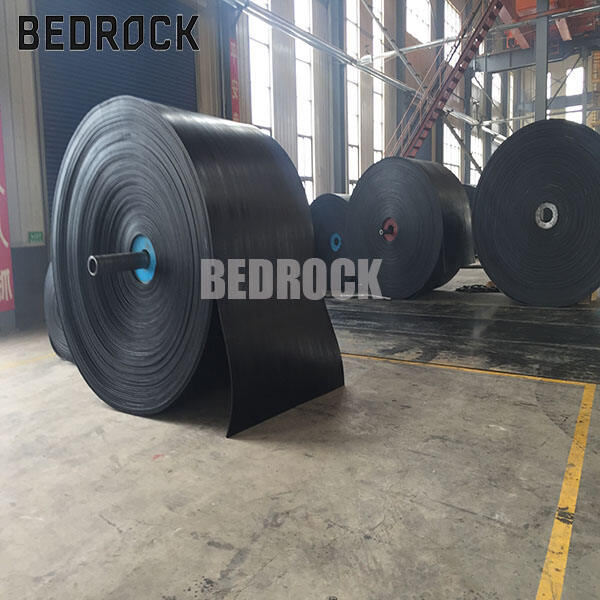

Steel reinforced conveyor belts are valuable conveyance tools utilized in factories, warehouses and other locations where objects need to be moved. These belts feature steel cables inside, which is an added strength that helps the belt last longer. They’re capable of carrying heavy loads and are efficient over long distances. This robustness allows them to lift large boxes, heavy machine parts or just lots of stuff without breaking. With steel reinforced conveyor belts, companies are able to get the job done as quick and secure. BEDROCK is a business that understands the value of those belts in order to move materials efficiently. With our steel reinforced conveyor belts, businesses can greatly improve their efficiency.

Efficiency in material handling using steel reinforced conveyor belts Steel Reinforced Conveyor Belts by Implicit definition are a belt of taking an action, because they do generally numerous benefits like you x91ll added actions drag and pull over time and stronger return than others. First, they are very strong. That is, they can bear heavy loads without risking a break. For instance in a warehouse, these belts can help shift pallets of goods from place to place in short order. If a belt breaks, workers can be delayed and forced to stop work. But with a belt reinforced with steel, these stops can become less frequent meaning more of the work in question will get done in a shorter time. Additionally, for specific applications such as high load conveying systems, our Multi Ply Rubber Conveyor Belt for High Load Conveying System can provide enhanced performance.

Steel cord conveyor belts are strong and very stable, but can have issues when worn in certain environments. One common issue is wear and tear. These belts are designed to handle heavy loads, but if used excessively or in rough conditions they can begin breaking down. To prevent this, you should keep an eye on the belts for any damage. If you notice any cracks or fraying, it’s best to just swap out the belt before it breaks all together. Another issue is misalignment. The belt is just not going straight sometimes. This occurs when the rollers aren’t arranged properly. This misalignment may lead to belt early wear and, even worse, accidents. To correct the problem, ensure that the rollers are lined up properly and adjust them if necessary. Frequent maintenance and inspections will help keep the belts running smooth. Furthermore, for industries that require belts capable of withstanding tough conditions, our High Strength Conveyor Belts for Long Distance Conveying in Hot Climate Conditions are ideal.

Another problem is binding or skipping. If the belt sticks to the rollers, it may cause material delays. This may occur if the belt becomes too dirty or they experience too much friction. To maintain the belt clean, occasionally you should clear away any dust or dirt particles. Using a belt cleaner can also help to limit sticking. Slips can occur when the belt is too loose or on a slick surface. To rectify this, simply verify if the belt is up to its tensed strength. If it’s too slack, you should adjust it so that the chain will move freely. BEDROCK suggests that, as in all such things it is best plan to adhere to a maintenance schedule that can help you prevent such damage and help your steel-reinforced conveyor belts last longer and work better.

Several industries rely on steel reinforced conveyor belts because they are strong and tough. Construction is one of the largest industries that uses these belts. In the field of construction, heavy materials such as stone, sand and bricks need to be transported from one place to another. These heavy loads can be conveyed via steel reinforced conveyor belts without breaking. This speeds up and makes the work safer. Mining is another industry to profit. In mining, workers have to get minerals and ore up the ground from deep underground. Such belts are also steel reinforced and capable of withstanding both the weight and the work conditions in mines, thus essential for this occupation.

Steel Reinforced Conveyor Belts The industrial sector also uses steel reinforced conveyor belts. Factories often must convey items swiftly from one part of the production line to another. By making Istona the strong belts, make you not to break your products in transportation. Similarly, steel reinforced belts are utilized in food processing plants as they can be manufactured to comply with food health and safety regulations. This can help them carry food products without worry, and still make them easy to clean. BEDROCK conveyor belts suitable for wide range of applications - the perfect solution for all varying needs.

Finding high quality steel reinforced conveyor belting for sale can be a difficult process, however, much like other product purchasing you have to put in some time and effort. The best place to start is, of course, the internet. Most companies, like BEDROCK, provide their complete conveyor belt range on their website. You can compare various options, read reviews and learn about the quality of the belts before making a purchase. It’s crucial to opt for a company that is known to produce products that are reliable. This will ensure that you are making your money’s worth.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.