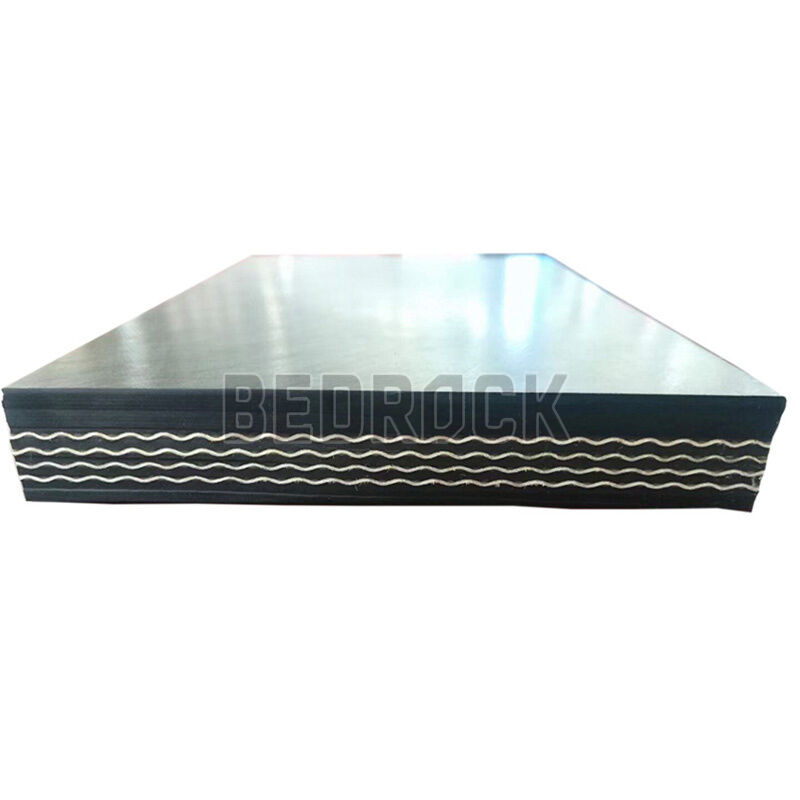

In open-pit mines located in arctic or cold regions, low temperatures can cause standard conveyor belts to become hard and brittle, drastically reducing their impact resistance. The Cold Resistant Conveyor Belt utilizes compounds based on natural rubber or BR (Polybutadiene), which have a very low glass transition temperature (the temperature below which rubber becomes hard and brittle). This allows the belt to retain its flexibility and impact strength in extreme cold as low as -40°C to -60°C, ensuring reliable startup and operation of the conveyor system.