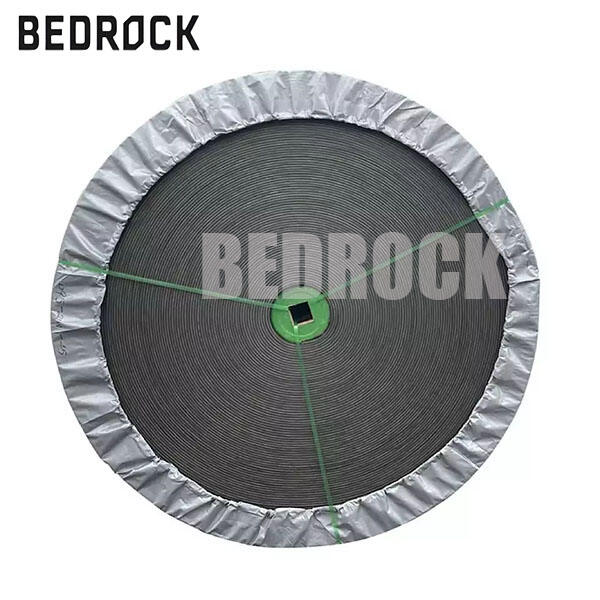

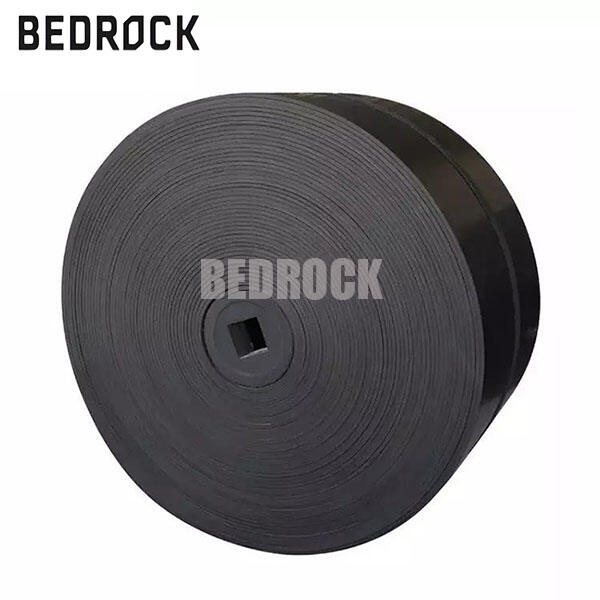

Flame-resistant conveyor belts are elements that every factory and warehouse must have. These belts support the transportation of materials from a place to another and protect staffs from fire hazards. At BEDROCK, we know how essential safety is to industrial facilities. It’s that commitment that we have put into our flame resistant conveyor belts. These belts are able to withstand tough conditions and can hold up against heat, flame, and wear. These belts not only protect from potential fire hazards, but also make workers feel confident that they have a tool they can trust when working hard everyday.

The flame retardant conveyor belt plays a vital role in the industrial safety process as this will prevent the possibility of occurrence fire accidents on the place. Many types of materials are highly flammable, particularly in places such as factories, warehouses and mines. For ex‐ ample, if a spark or fire is brought into contact with flammable matter, it will cause an explosion. And this is where flame resistant conveyor belts are employed. They are manufactured with certain materials that do not readily burn. This enables them to continue moving around materials, even in dangerous situations. For example, using an Fire Retardant Conveyor Belt is crucial in such environments.

Coal mines are a good example, where risk of fire is very high. Flame Resistant Conveyor Belt is an absolute necessity in environments where high flame resistance is required. They keep coal moving as well as make sure a possible fire does not turn into a disaster. We are proud to bring you the best in class, tested and certified products to help make your business a safer place for everyone. Knowing that you have a flame retardant conveyor belt in place for your operation would be assuredly provide workers with peace of mind, removing the concern from fire hazards so that they can concentrate on their work.

Selecting the correct fire resistant conveyor belt is also critical for maintaining safety and efficiency during operation. First, consider what kind of stuffs you are going to carry. Different materials have different risks. That’s because some tasks require more flame resistance than others: Transporting coal or chemicals, for example, requires a stouter level of protection than carrying heavier items like metal parts. That’s why it’s important to know what you’ll be carrying. You may also consider using a Sidewall Conveyor Belt for specific material handling needs.

Finally, don’t neglect safety certifications. Search for belts that are industry compliant. This is to see that the belt has undergone testing and proven itself as effective as possible, in preventing fires. We at BEDROCK care about safety, and we make sure our products meet all of your safety needs (and then some). By putting these factors into play, you can select the ideal flame resistant conveyor belt for your company and keep your personnel safe while ensuring that productivity never misses a beat.

If you’ve decided that conveyor belts with flame-resistant properties are exactly what you need in your operation, it is crucial to know where to find the best quality ones at wholesale prices. One big winner will be industrial supply stores or warehouse and factory material websites. Such places offer a lot of variety including the fire resistant conveyor belts those that are products intended to be long-lasting. Another good alternative is finding manufacturers through direct contact. Companies like BEDROCK manufacture conveyor belts and sometimes provide volume discounts. This is a benefit in that more belts can be had for less money. Online marketplaces are also helpful. Websites that connect buyers and sellers mean you can compare prices and choose the best deals. You can also check out other customer reviews to see which belts are the highest quality. It’s also wise to request samples before you shell out a lot of money. This will enable you to verify that the belt fits your requirements. When purchasing fire resistant conveyor belts always take into account the size and type of your conveyor system. Various systems might require different sizes or style of belts. BEDROCK offers choices across industries, ensuring that there’s a fit for your specific workplace. Search for belts that have been safety tested, as these are able to hold out well at high temperatures and against flames. Safety is always going to have the upper hand. Also think about the seller warranty. Insurance A good warranty is now an even more important insurance against something going wrong and having to fork out extra money. By following these steps, you'll be able to find a good quality flame resistant conveyor belt for a decent price – that and your factory will remain working without issue.

Flame resistant conveyor belts are essential in various industries, but they can also be problematic. One problem is simple wear and tear. The belts can get damaged over time from heavy use or from exposure to high heat. The only way to rectify this is regular inspections. Frequent checks of the belts can enable you to catch issues before they turn critical. If there are any cracks or the belt is fraying, it’s best to replace this belt straight away. Another problem is that the belt becomes coated with matter. Sometimes, materials can adhere to the surface and reduce efficiency of the belt. The belts need cleaned to fix this problem. With the right tools and cleaning solutions, that belt can be kept in good shape. Also, it’s critically important that the conveyor system is properly maintained. If the system is not in line, it will wear the belt out fast. This can be mitigated by regular maintenance. Also the use of an appropriate flame resistant conveyor belt specifically used for the service proposed is mandatory. BEDROCK provides multiple belts for diversified use. Opting for the right one now can save you time and money in the future. Another common problem is overheating. And if the conveyor belt gets too hot, it can become a fire hazard. To avoid over-heating, ensure there is no overload in the system. Observe the weight limits recommended by the manufacturer. If overheating is a problem time and time again, then change up your usage or buy better cooling. If you want to get the most out of your flame retardant conveyor belt then addressing these common problems is a must and can also keep your workplace safe.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.