High temperature belting is an essential for in most factories and industries. These belts help machines run better, especially when they’re hot. These are designed to withstand high heat, so you will find them in bakeries, steel mills and other such places. The proper belt can help keep machines operating efficiently, a plus for any business. A belt that breaks or doesn’t function properly can cause things to move at a glacial pace. That’s why it is vital to select the right high temperature belting for what you need. Companies like BEDROCK create strong and tough belts that can withstand all heat condition.

It may be difficult to find the optimal suppliers for high-temperature belting, but it is not impossible. First off, you might consider searching online. A great many companies do business through their websites, some with special pages for wholesale. Search for sellers that have good reviews and deliver quality belts. You might also consider trade shows or industry events. There are usually many suppliers at such events in one place, so it takes little effort to see what people have and speak to them directly. You may also be able to find places in your field for which other people have positive recommendations. Other companies may have leads on suppliers they trust. You can also get lucky, and find people who know others - which can help you land those gems in the rough.

Do not overlook the location of the suppliers, by all means. So if they are nearby it might be easier to get products cut quickly. You may have to shell out for shipping too if you’re ordering from a distance. Be sure to obtain bids from several suppliers so you can compare prices. Some businesses may have bulk-order offers, so inquire about any discounts. And finally, when you find a supplier you like, don’t be afraid to ask questions. Ask them about the materials of their belts, heat performance and what kind of warranty they have. You want to have a supplier that will be happy to educate you on what you are driving.

Selecting the correct high temperature belting is a challenge. You need to figure out what you will use the belt for. Different industries have different needs. If you’re working in a bakery, for instance, you can wear a belt that’s great at withstanding high heat from ovens. And in a metal-making factory, the belt must even withstand hotter temperatures. Feya says that’s why it’s essential to consider the situation in which she belt will be warning.

You should also take into consideration the size of the belt. Be sure to measure the spot where the belt will sit. If it is too long or too short, you will not be able to get it to work right. You also want to consider the texture of a belt. Other belts are fabricated of rubber or metal, or from special heat-resistant materials. Each has its positives and negatives. For instance, rubber belts may be more flexible but may not have as long of a lifespan at very high temperatures. Metal belts are likely to be more durable but can also be heavier and more difficult to install.

High temperature belting material is a common application in the food processing and manufacturing industries because machines are required to cook and process very hot foods. But there are issues of utilization when it comes to this kind of belting. Another major problem is that the belting can wear prematurely if it’s not manufactured from the proper materials. If the belting is too soft, it can break or become damaged and disrupt production on the factory floor. Another issue is that high temperatures can lead to stretching, or loss of shape in the belting. That can force the machines to labor less efficiently, which can slow production down. Both of these problems can be solved by selecting the proper high temperature belting. Just be sure to find belting that’s designed for high heat and made up of sturdy materials.!BEDROCK provides solution for belts food that can withstand high temperature and is dependable. It’s also wise to inspect the belting periodically for any sign of wear. If the belt shows any damage, it’s probably best to change the belting as soon as possible so you don’t end up with more serious problems down the road. Proper installation is also important. Misinstalled belting may be the result of increased stress and quicker wear. Be sure to follow the manufacturer's instructions. With careful attention and selection you can ensure that your machines will keep on running without problems brought on by hot-tex belting.

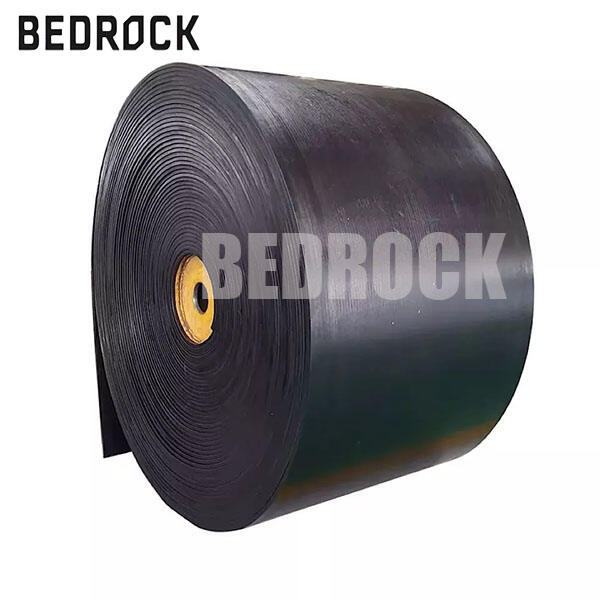

This sort of high temperature belting at wholesale prices is difficult to find, but necessary for many businesses which use such products. Some of the best sources to purchase the high temperature belts are directly from manufacturers. BEDROCK is your high temp belting of choice at competitively low wholesale prices. You can cut costs by purchasing directly from manufacturers who give you better prices without the middleman. Or, you can try online marketplaces for industrial supplies. These sites also tend to have a greater variety of products and can more easily price-compare between different sellers. Just make sure to research and check ratings before buying so you can get it from a trustworthy source. Another option that may benefit you is to purchase belting by the roll if you have a large quantity of use for it . Purchasing in bulk can save you money over time. There are also some companies that may provide discounts to first time buyers or if one is buying in bulk. And do not forget to inquire about warranties or guarantees. A strong warranty will provide you with peace of mind that what you’re buying is a quality product. Don’t forget to factor in shipping costs, too — those can add up just as quickly. With a little bit of research and shopping around, you can find quality high temperature belting at prices that won't break the bank.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.