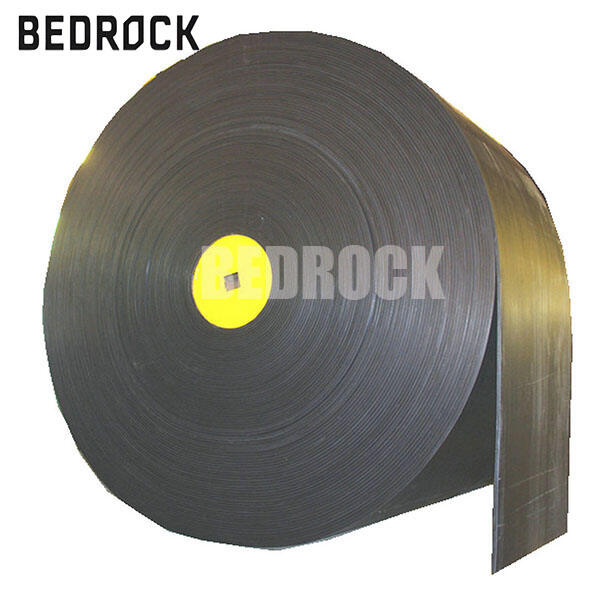

Heavy conveyor belts they are really important in lots of industries. They move heavy stuff from one spot to another easy. You see them in factories, warehouses and construction places. Think about like a big moving road that carry rocks, boxes or even food sometimes. At BEDROCK, we know these belts are super vital for keep work going smooth. They save lots time and effort, make jobs quicker and less hard. When company use heavy conveyor belts, they can pay more attention to important things, like produce good products and take care customers.

Heavy conveyor belts is great for so many reason. First thing, they carry very much weight and dont break that easy. Like in factory, the belt move big metal piece, keep worker safe and lower chance get hurt. Instead lifting heavy thing with hand, worker let belt do the tough job. This save energy and avoid accident too. Also these belts make everything faster because material move automatic, so worker can do other task. For example if belt take boxes from production to shipping area, people can pack and send quicker. Especialy in busy season like holiday, this help a lot. And they can bend around corners, fit in tight space no problem. At BEDROCK we make belts that suit perfect to any place, so productivity go up. Last, heavy conveyor belts reduce waste becuase product move careful, less damage happen. Less broken stuff mean save money. Company who use them usually see profit increase, move more product in short time. So overall heavy conveyor belts make work much easier and effective. For high load applications, consider our Multi Ply Rubber Conveyor Belt for High Load Conveying System to maximize efficiency.

Even if heavy conveyor belts are mostly reliable, sometime problem come up. Know how to fix them is key to keep operation smooth. One usual issue is belt slipping. This happen when belt not tight enough or something stuck there. To solve, check tension and tight it if loose. If object block way, just remove it. Another thing is strange noise from belt. Maybe rollers or bearings got issue. Listen good to find where noise come from, then replace worn part so it run quiet again. Sometime belt get tear or hole. For small one you can use special glue or tape fix it. But if damage big, better replace whole belt. Regular maintenance is the most important to stop these problem. Check belt often and keep clean help prevent many trouble. At BEDROCK we suggest make maintenance schedule so catch issue early. Being proactive save money and time. Troubleshooting can feel hard but with right knowlege and tool, you keep conveyor belts in good shape.

If your business need heavy conveyor belts, know where get best one with good price matter. Start by find supplier specialize in industrial stuff. Company like BEDROCK sell high quality heavy conveyor belts that last long. Search online is good idea, many have website show product, review and price compare. This way you find best deal. Also check local supplier sometime, buy near save shipping cost.

When you pick supplier, ask about bulk buy. Larger quantity order usually give better price. BEDROCK give discount for wholesale, help business save. Ask too about material use in belts, good material mean product last longer. Supplier should explain why their belt worth it. Dont forget look at warranty, good one show company trust product. If problem happen you want support easy. Customer service important also, choose company easy contact when need help. After find right supplier, order and start use new heavy conveyor belts. With good one, they fit your need and make business run smooth. For transporting materials in challenging environments, you might want to look into our Heavy Duty Rubber Conveyor Belt for Mining and Quarry Applications.

Heavy conveyor belt world change fast with new tech. Company like BEDROCK always try improve product. One big change is use stronger material. New one handle more load and last longer then old. Some belt now use special rubber or strong fabric make more durable. They work in hard place like factory or construction without break easy.

Another cool thing is new design, some belt lighter and easy install. This save time money becuase setup faster. Also advanced tech for monitoring, many belt have sensor track performance. If issue, sensor alert so fix quick. This prevent accident and keep run smooth. Automation more common now in conveyor system. Machine do more work with less people. Automated belt move item nonstop, make operation efficient. BEDROCK lead in use automation for faster reliable system.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.