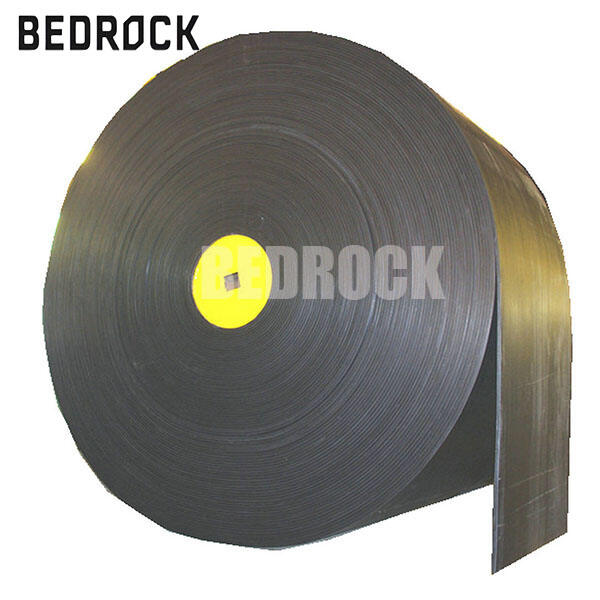

Mining Belts Are Extremely Valuable Products Used To Move Heavy Matter Such As Rock And Ore From Mines And Also To Use For Crushing Machinery. They function like long, strong conveyor belts made largely of rubber. Mining companies want these belts because they can carry massive loads safely and quickly over long stretches. With weak belts, mining work is slow and unsafe. BEDROCK produces durable rubber mining belts while maintaining the same uncompromising quality that you have come to expect from manufacturers. These belts are not the type that break, and they can work with heavy weight every day. Mining operations can be rough on belts, which might be exposed to weather and sharp objects that cause damage, but BEDROCK’s products were built to withstand those conditions. This, in turn, allows miners to be confident that these belts will work without interruption — ultimately saving time and money.

Rubber mining belts can be difficult to find a good supplier for. There are many companies selling belts, but not everyone is as sturdy or long lasting. Wholesale suppliers are the way to go if you’re purchasing a lot of belts, as they provide cheaper prices and, typically, better quality. If you purchase from a supplier who doesn't know what’s required in mining, belts might break soon or wear out fast — and that’s hugely problematic on a worksite. BEDROCK markets its belts via a network of reliable wholesale suppliers that understand what mining firms want. These suppliers guaranty high quality of belts before sending to the market. They maintain an inventory of belts so miners don’t have to wait long, even if they order lots at once. It’s worth it to see if the supplier offers support after purchase. Occasionally belts tear or need to be replaced, and smart suppliers assist with such issues promptly. One of the methods you can use to get reliable suppliers is by inquiring within the mining community or reading up on reviews from other buyers. Plus, suppliers who work closely with manufacturers like BEDROCK have a better understanding of the product and can provide good advice. It’s a good idea to avoid those suppliers that sell all kinds of things without any special knowledge on mining belts. When I buy in bulk, prices count, but quality counts more. A cheap belt that breaks constantly costs more in the long run. The finest suppliers are going to sell high quality goods at fair rates. Occasionally, suppliers provide samples or trial order so buyers could test the belts before making a big purchase. This helps avoid surprises. Great update, I had a laptop stolen on Ratac so it is worth doing. Good suppliers will also give you the size of the belt and material plus warranty details. This data will allow buyers to better prepare their mining efforts. Picking the best wholesale supplier removes the hassle and produces better results overall. For instance, consider looking into a Sidewall Conveyor Belt for enhanced material handling.

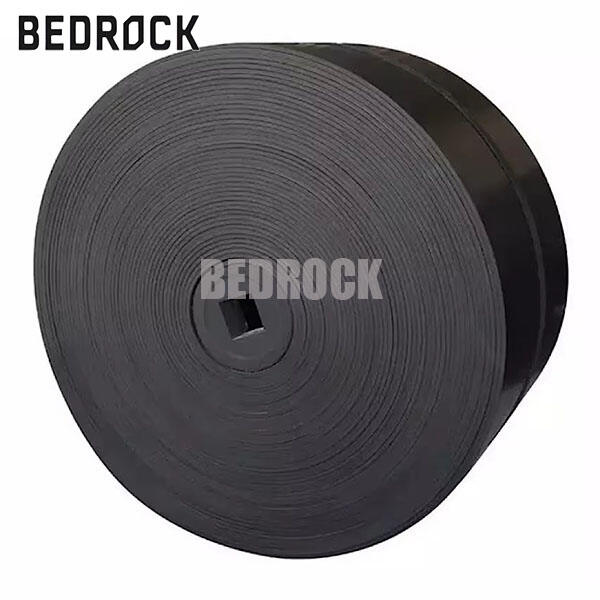

If you are amassing rubber mining belts, it is important to understand what makes a belt strong and valuable. A good belt should be strong but still pliable. It has to be able to withstand cuts, tears and wear because mining sites have sharp rocks but also heavy loads.” BEDROCK’s belts include special rubber layers that protect them from harm yet allow them to bend around rollers and pulleys without breaking. The belt grip is also another important factor. Good belts, on the other hand, have a surface that grips materials and prevents them from sliding off while being conveyed. This prevents wastage and maintains order on the work place. Some belts are also flame-resistant, because mining sometimes takes place in hot places or machines can make belts warm. If a belt melts or stretches, it is not effective. The thickness of the belt is also important. Thicker belts can carry heavier loads, but they also are more expensive and may be more burdensome to handle. Thickness should be selected to suit individual mining machines and loads the buyers operate. Bulk purchasers also seek out for belts that will last a good long while. It’s why the belt can run for many hours or even days before it has to be replaced. This saves money on replacing belts frequently. Another point: The belt’s weight. Heavy belts can require more energy to operate, so BEDROCK designs its belts to provide a balance of strength and lightness. The inner structure of the belt is also very important. Tough cords or fabric inside the rubber help this long belt hold its shape and prevent stretching. Loose belts can shut down machinery or dump material. Some belts also have effective resistance to water, oil and chemicals often present in a mining environment. These designs prevent the belt from wearing out fast. Consumers should also consider ease of installation and repair. Some belts can be repaired easily if they get small cuts. This reduces downtime. Finally, safety is key. Belts should not generate hazardous dust or discharge sparks in dusty mines. BEDROCK specializes in producing belts that keep workers safe working hard. Combine all of these features together and you have a winner, not to mention having more than one for this price is too good to pass up! The right belt makes mining more streamlined, safe and most importantly – more economical.

Rubber mining belts are very useful in mining and other such places which helps transport rocks, minerals etc.IntervalSince1971 Like long, strong conveyor belts made of rubber, they can pick up dust and transport it for thousands of kilometers before dropping the charge. They are meant to be workhorses hauling materials around the mining site. Employing rubber mining belts among the mining companies speeds the work, and provides better protection to workers. Miners don’t have to carry heavy loads by hand, which can be both dangerous and slow, when using these belts. Instead, the belts glide materials along speedily but in a controlled manner, allowing workers to get more done in less time.

Rubber mining belts help to increase productivity by working non-stop. In other words, the belts are not stopped and started again, which allows material to keep moving without delay. This slow trudge is crucial for large mines that must move tons of rock per hour. The belts are very flexible and strong because they’re made of rubber. They are resistant to heavy and abrasive materials and protect the screen sections without easily breaking or damaging. It’s a great time-saver, and anything that helps minimize the amount of time spent repairing equipment also enables your work to move along without being constantly interrupted.

Another reason that rubber mining belts are beneficial is safety. Mining can be dangerous, as workers handle heavy objects and sharp tools. With materials travelling along rubber belts, workers can be safer because they don’t have to heave, carry or even tote heavy loads themselves. It’s not just for structure though, rubber is really good because it holds onto the rocks and stuff; nothing slides out super easily. This minimises rockfalls or falls of materials accidents. The slip resistant rubber belting protects the workers from crushes and abrasions during extraction processes.

One key aspect is the rubber quality. The better quality of rubber also is sturdier and more pliable. It’s strong enough to withstand rough surfaces and heavy loads without tearing or cracking. For the soles of the boots, BEDROCK deploys a special rubber that’s able to resist cuts, heat and chemicals found in mines. This type of belt, then, can continue to work effectively when conditions are tough. Its the same kind of rubber, just its stiffer(hardness-wise)If your rubber is too soft or bad then it will break down fast and not last very long.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.