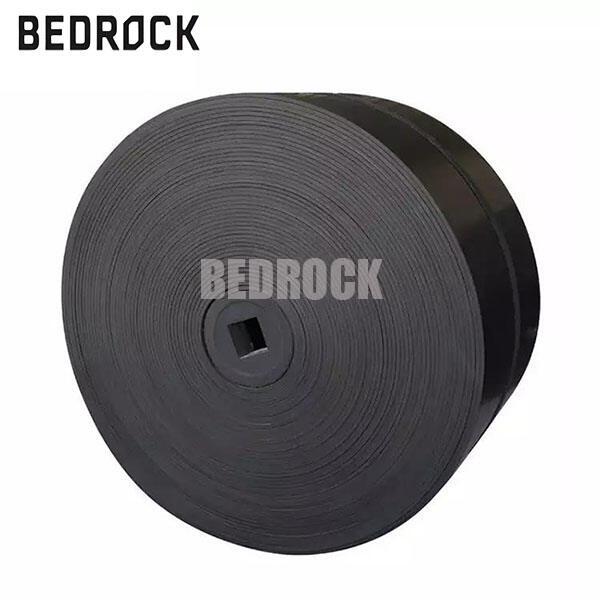

Conveyor belts are highly used in mining. They are used to help transport heavy materials such as coal, minerals and rocks. Instead of workers carrying all the materials by hand, which is exhausting and risky, conveyor belts can get it done much more quickly. This is why mining becomes simpler and safer. At BEDROCK, we are dedicated to creating long-lasting conveyor belts that make mining operations run more efficiently. Miners save time and resources using these systems and are also able to provide even more protection for their crew.

Conveyor belts are an even more efficient way to work in mining. When you put it that way, the process of moving heavy things up from deep below the ground can be awfully slow. They can only be transported over very limited distances, but material can be moved rapidly on a conveyor belt. Visualize a group of miners sweating away, hacking holes in the ground to extract valuable minerals. Rather than stopping frequently so workers can carry these materials to trucks or processing plants, the belt never stops. In a few hours, it can transport tons of material. Additionally, using a flat belt system can enhance the efficiency of mineral transportation further.

Moreover, technologies have made today’s conveyor belts ever smarter. Some belts can also automatically adjust their speed depending on how much material they have. This prevents jams or overloads and keeps everything running smoothly. BEDROCK’s conveyer systems also have things like sensors that alert workers when something is awry, to reduce the number of accidents. All these improvements make conveyor belts the perfect accessory to assist in making mining more efficient, safer for staff members and an all around clearer operation.

The mining industry is also something averagely similar like the newspaper industry, not necessarily a conveyor belt where everything that comes in one end goes nicely around to all the places that want it coming out of the other. For example, belts tend to become worn or damaged through the presence of abrasive materials. When one of these breaks, work at the mine can come to a halt, contributing to delays and lost income. In order to address this, it requires a little bit of maintenance. Like at BEDROCK, we suggest closely monitoring conveyor systems to catch any future issues sooner rather than later. Even simple tasks like cleaning or tightening can have a major impact. Regular checks for abrasion conveyor belts can prevent unexpected downtimes.

Mining relies on being able to move plenty of material from one place to another, and conveyor belts are a key part of that. But to maintain their efficacy, it’s important to take good care of them. So, to begin with, don’t forget to inspect your conveyor belts. This includes checking for wear and tear, such as cracking or holes. You should do what you can to repair damage when you see it. Regular maintenance will also help ward off bigger problems down the line. Another important part of maintenance is keeping the conveyor clean. Dust, dirt and such other small objects can accumulate on the belt. If the belt is dirty, it may slip or run poorly. Hosing it down with a water hose or special cleaning tools can help keep the conveyor belt clean.

Another key point of maintenance is to see how tight the belt rides. If the belt is too loose it can fall off the rollers. If it’s too tight, it can stress the system and cause it to fail. Setting the tension of the belt at the right manner is crucial to ensure everything works symptom free. Regular inspections by trained professionals are a good idea, too. These are professionals who know what to look for and can help you catch issues before they’re major. Good maintenance is something you’ll want to keep in mind as the upkeep of your home can save time, and money in the long run. Taking care of the conveyor belts makes it last longer and be more efficient. For mining purposes that's exactly what you're looking for! At BEDROCK, we specialize in keeping your conveyor belts efficient day-to-day.

FINDING THE BEST CONVEYOR SYSTEMS FOR SALE When it comes to a place that you can trust to purchase your conveyor systems from some of the best manufacturers call Capital Bearing Supplies Pty Ltd. Not all conveyor belts are created equal, so quality is paramount. 1) Research Sellers / Manufacturers The first step in our online shopping guide is to do your research. You need a company that’s established for manufacturing durable, strong belts created to support heavier materials. Check out other customer reviews to see what others think. You can also have a look at other companies that are satisfied with the conveyor belts as there is a good chance you will be too.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.