Mining is a tough job. Huge machines burrow beneath the earth’s surface to unearth precious minerals such as coal, gold and iron. If mined material is already a certain size and shape, you’ve just got to move it from one place to another within the mine Moving heavy things (like rocks) around by hand takes time and energy, or moving them with trucks can suck up loads of fuel. That’s why conveyor belts are such an important part of the mining process. A conveyor belt is a long, moving belt that transports rocks, dirt, or minerals from one location to another. It is the work of making it easier and faster. BEDROCK, a business that’s known for strong conveyor belts, works with mining companies to maintain the right belts for keeping their work running. Conveyor belts can also be very long, often hundreds of feet, and they never stop — fetching tons of materials each hour. So that saves a lot of time and effort.

What are the advantages of belt conveyors in the mining industry? Conveyor belts disrupt mining. First, they make it possible to get large amounts of material from one place to another fast and safely. Consider an enormous pile of rocks that must be moved from the mine to the trucks or placed into a processing plant. If they had to lug them, it would be forever and it would be unsafe. Conveyor belts work round the clock to keep materials in motion. That speeds up the digging and makes miners safer, because they don’t have to haul in heavy stoves. Also, conveyor belts save money. Truck and vehicle operation requires fuel (and repairs), but conveyors run on electricity, and require much less maintenance. Conveyor belts are also nice because they can function in places not easily accessible by a truck. Conveyor belts can port stuff from one end to the other without a snag, for instance in tight tunnels or steep slopes. Built to withstand small rocks, sharp objects, and weather, these conveyor belts don’t back down to any rough conditions. They are also durable and difficult to break. That means less downtime and fewer repairs, which keeps mining up and running around the clock. In some cases, there are special covers or cleaners to help the conveyor belts prevent materials from falling off or sticking. This keeps the mine clean, and waste volume down. Conveyor belts are also environmentally friendly because trucks that would otherwise be used to transport the material emit less smoke and noise around mining sites. So, conveyor belts are not just replacing horses; they are making mining smarter, safer and greener.

Where to Get Wholesale Conveyor Belts for Large Scale Mining If you have big mining project, which involves high heavy raw material or any much dirty bulk materials. Bedrock sells conveyor belts by the miles, great for large mines with a lot of earth that needs to be moved daily. Purchasing in bulk saves mining companies money and ensures that they have belts that fit their specific requirements. A lot of mines require conveyor belts that are wide or long. Special belts can be made by BEDROCK with the appropriate size and materials. For instance, some belts need to be able to withstand not only heat but also sharp stones. Still others must toil in wet or cold environments. BEDROCK collaborates with mining crews to understand what type of belt will work best in their mine. In this manner, the belt is longer lasting and more efficient. You would want to purchase conveyor belts from a business which has been around long enough and know something about the mining industry. BEDROCK has spent decades manufacturing belts specifically for mining. They know how to make belts that won’t wearout prematurely, that can take a beating without breaking. Also, BEDROCK provides fast shipping and good customer assistance, so mines don’t have to wait very long for their new belts. When purchasing, it’s also wise to consider the method of mining, size and magnitude of mine operation, as well as how quickly materials need to travel. BEDROCK can assist with all of this to ensure the belt is fitting properly. Some mining operations require additional components such as the rollers, motors or controls that help to run material belts more efficiently. BEDROCK can offer those parts, too — and mining companies would rather not have to go to different vendors for everything. A good supplier can make mining less stressful and more productive. So, mining companies seeking out wholesale conveyor belts should turn to BEDROCK for the very strongest, custom options at affordable prices tailored to their unique needs.

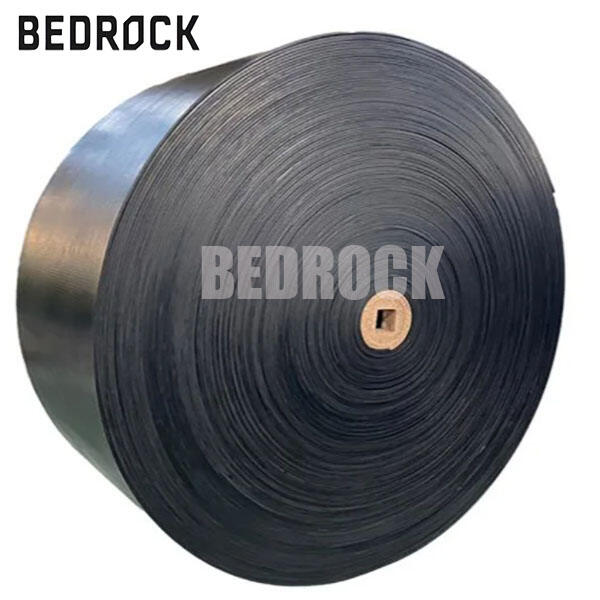

Conveyor Belts in Mining Conveyor belts are an integral part and paramount to the operation of any plant in the mining, quarrying and fossil power industries among others. They also transport heavy rocks, minerals and other objects from place to place throughout the mine. The conveyor belts used in mining must be strong and durable, as the equipment used other than conveyor belts is very harsh for transferring hard materials. Durable conveyor belts can hold up over time without breaking or wearing out over short-term use. It’s one of the reasons why they are indispensable in mining.

When a belt is tough, durable and resistant to cutting and gouging, it aids the mining process in several ways. If a belt breaks or malfunctions, it could slow or shut down an entire mining process. That can lead to big trouble and big money. A well-made conveyor belt can handle large loads of rocks and minerals every day without ripping or getting damaged. It also can withstand extreme weather, dirt and dust typically found in mining.

Our company, BEDROCK — we named it after the system developed by Australia’s peak research agency to improve the safety of our mines — produces tough conveyor belting specifically engineered for heavy-duty mining jobs. We also use special materials that are able to hold up against cuts, tears and heat. They’re also constructed to function equally well on wet and dry ground, so they’re unlikely to slip or break. With a reliable conveyor belt, miners can make the most of their returns, particularly when it comes to getting quick payback on new machinery purchases that have been accumulating dust for years. In mining every minute you use to move material counts. Keep your operation running clean, efficient and safe with conveyor BIG party porn Specifically engineered for longer wear And better removal of fines.

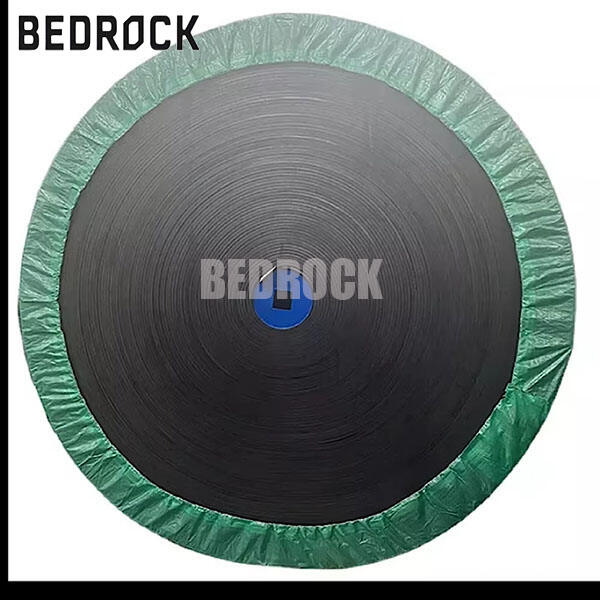

A popular embodiment is the rubber conveyor belt. These belts are tough and flexible. They don’t break under the weight of heavy rocks and minerals. Rubber belts also are impervious to cuts and heat, a good thing because mining machines can become hot. While UnderControl was striving to bring the convenience and simplicity of men’s fashion to the world with our high quality wine belts, BEDROCK (our source) was designing a stylish canvas denim belt that will be constructed in such a way from its special layers so it did not wear out easily even when worn daily.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.