Factory Direct Sale of Biscuit Transportation Accessories Cotton Conveyor Belt

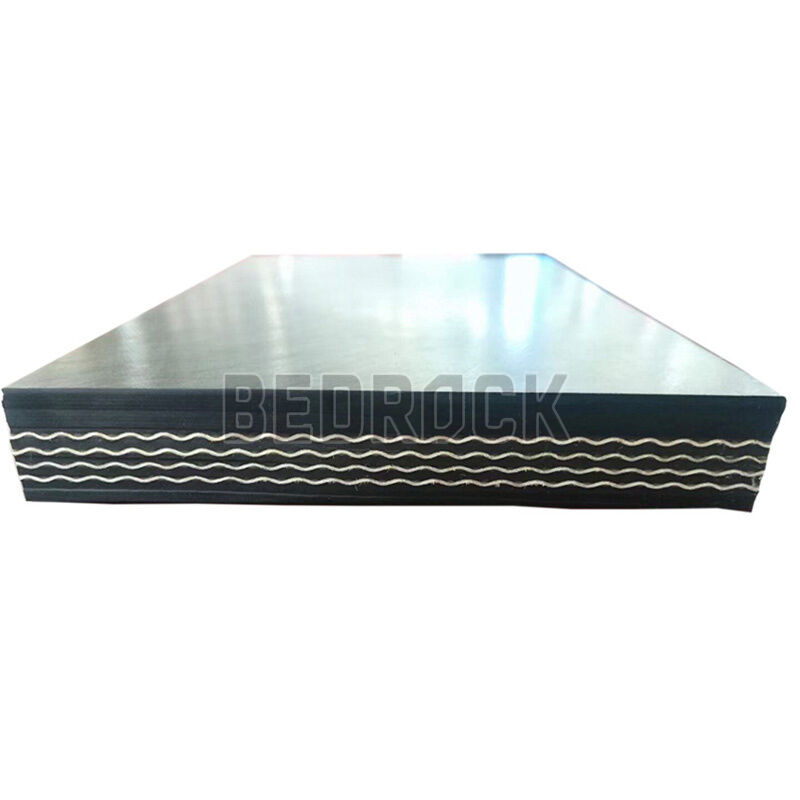

Primarily composed of natural cotton fibers (such as long-staple cotton), these fabrics are woven into high-density layers (single-layer or multi-layer composites) through interlacing warp and weft threads. The surface may be coated with rubber (natural/synthetic) or other abrasion-resistant coatings to enhance protective properties. Certain models undergo impregnation treatment (e.g., rubber emulsion impregnation) to improve overall strength and tensile resistance.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

This construction not only ensures durability but also provides a balance between flexibility and robustness, making the fabric suitable for various demanding applications. The weaving techniques employed, such as plain weave, twill, or satin weave, determine the texture and performance characteristics of the final product. For instance, a tighter weave increases resistance to tearing and punctures, which is critical in industrial or outdoor settings.

In addition to structural integrity, these fabrics often undergo additional treatments to enhance specific properties. Water-repellent finishes are applied to prevent moisture absorption, ensuring that the material remains lightweight and functional in wet conditions. Similarly, flame-retardant coatings can be integrated for use in environments where fire safety is paramount. These specialized treatments expand the versatility of cotton-based fabrics.

The breathability of natural cotton fibers further complements their engineered enhancements. This inherent quality makes them comfortable against the skin while maintaining protective features. Moreover, advancements in textile technology have led to eco-friendly variants, incorporating recycled materials or sustainable production methods without compromising performance.

Overall, this combination of natural fiber composition, advanced weaving techniques, and tailored surface treatments results in fabrics that meet stringent industry standards. offering both reliability and adaptability across diverse sectors. Their continued evolution underscores a commitment to meeting modern demands for durable yet sustainable solutions.

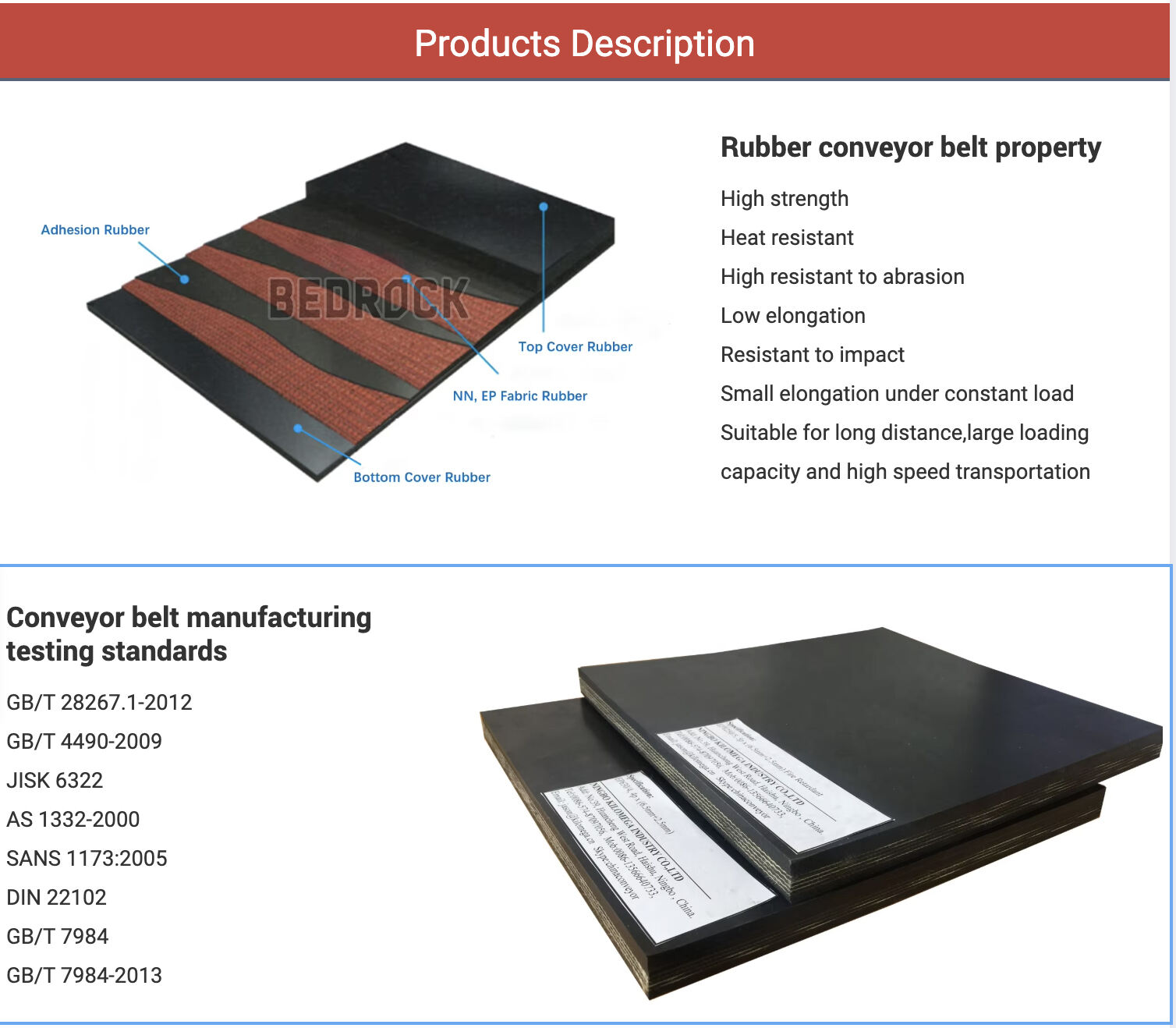

Specifications

| Fabric specs | Ply thickness (mm/p) | Strength series | Cover thickness | Widt h(m m) | ||||||

| 2ply | 3ply | 4ply | 5ply | 6ply | Top | Bottom | ||||

| NN-100 | 0.75 | 200 | 300 | 400 | 500 | 600 | 1.5–8 | 0–4.5 | 400–2500 | |

| NN-150 | 0.80 | 300 | 450 | 600 | 750 | 900 | 500–2500 | |||

| NN-200 | 0.90 | 400 | 600 | 800 | 1000 | 1200 | ||||

| NN-250 | 1.15 | 500 | 750 | 1000 | 1250 | 1500 | ||||

| NN-300 | 1.25 | -- | 900 | 1200 | 1500 | 1800 | 100–2500 | |||

| NN-400 | 1.45 | -- | -- | 1600 | 2000 | 2400 | ||||

| NN-500 | 1.55 | -- | -- | 2000 | 2500 | 3000 | ||||

Applications

Cotton Conveyor Belt is suitable for light-load, low-speed conveying applications. In textile mills, it can be used for transporting cotton yarn and fabric rolls; in agricultural processing, it conveys cotton bales and grains; in light industrial workshops, it handles small parts, paper sheets, and other sheet-like or granular materials.

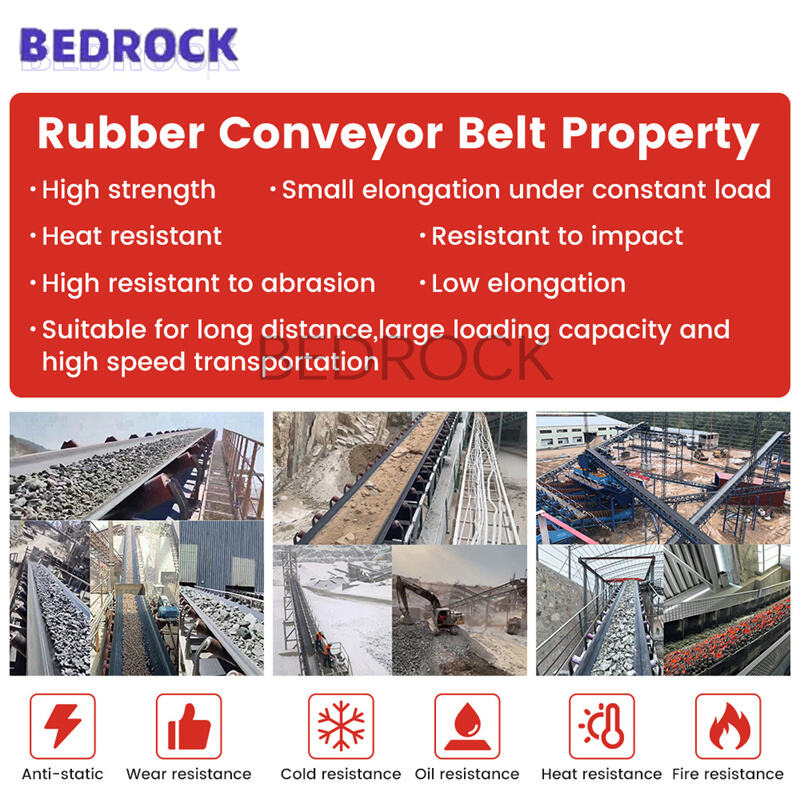

Advantages

1. Lightweight texture with moderate spreadability

2. Skin-friendly and low corrosion

3. Routine maintenance requires only cleaning or spot repairs, with moderate service life

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.