Customized Chevron Conveyor Belt Highly Durable Conveyor Belt for High-temperature Materials

Chevron conveyor belts are designed with a rubber layer featuring a patterned surface, a flat rubber layer on the non-working side, and a core. The patterns on these belts can be open or closed, and they come in high, medium, or low profiles. These belts are ideal for transporting powdered, granular, and small-block materials on inclines up to 40 degrees, as well as for moving bagged items.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

Chevron patterned conveyor belts represent a specialized category of bulk handling equipment, meticulously engineered to address the inherent limitations of conventional flat belts in steep-incline conveying scenarios. By integrating strategically designed protrusions onto the belt surface, these systems fundamentally overcome the persistent issues of material rollback and slippage, thereby enabling reliable transportation at angles previously deemed unachievable with standard conveyor systems. The operational excellence of chevron belts stems from their sophisticated structural composition, which harmonizes multiple functional layers into a cohesive, high-performance unit.

The foundational element of these belts is a high-tensile strength carcass, commonly manufactured from synthetic fabrics like polyester or nylon, which provides the necessary mechanical robustness to withstand substantial operational tensions and dynamic loading conditions. The underside of the belt features a uniformly smooth rubber cover, engineered for minimal friction and consistent interaction with conveyor idlers and drive pulleys, ensuring efficient power transmission and tracking stability. The defining feature, however, resides on the carrying side: a series of integrally molded, vulcanized chevron patterns. These patterns are not merely surface appliqués but are fused into the top cover, creating a permanent, wear-resistant profile that acts as both a non-slip surface and a physical barrier, effectively containing and elevating bulk materials.

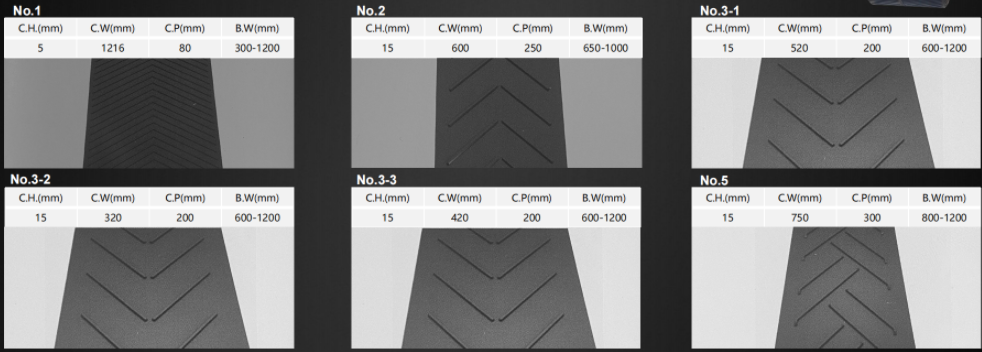

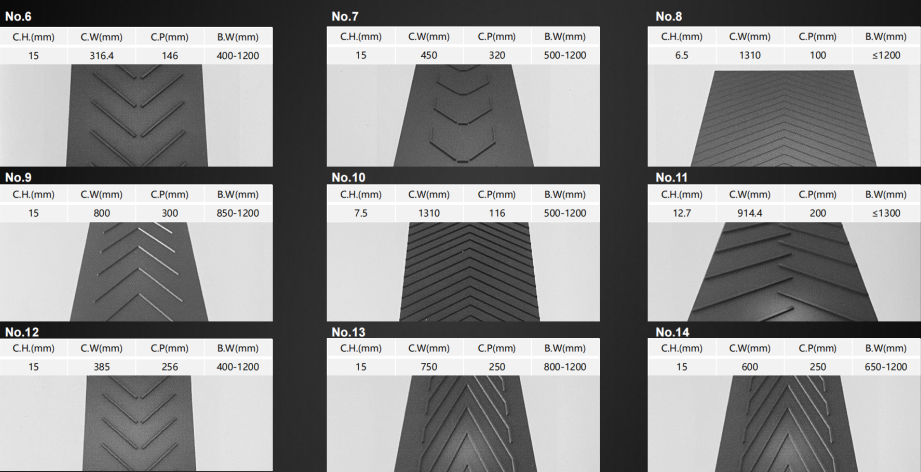

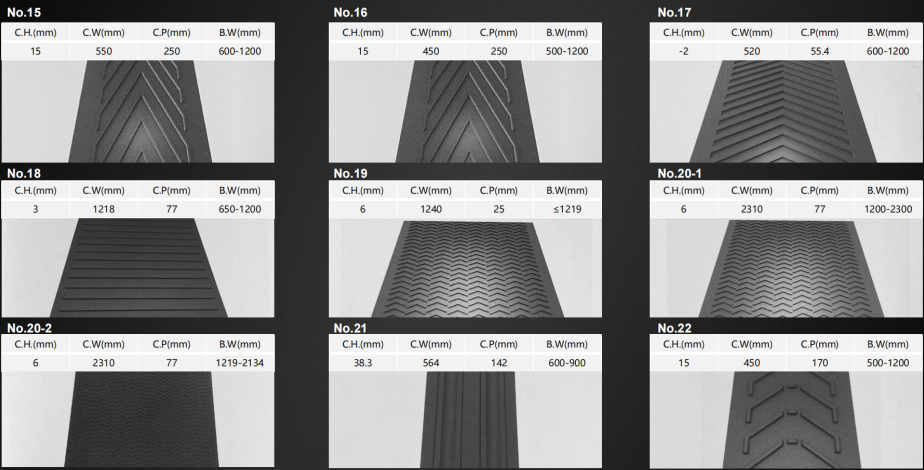

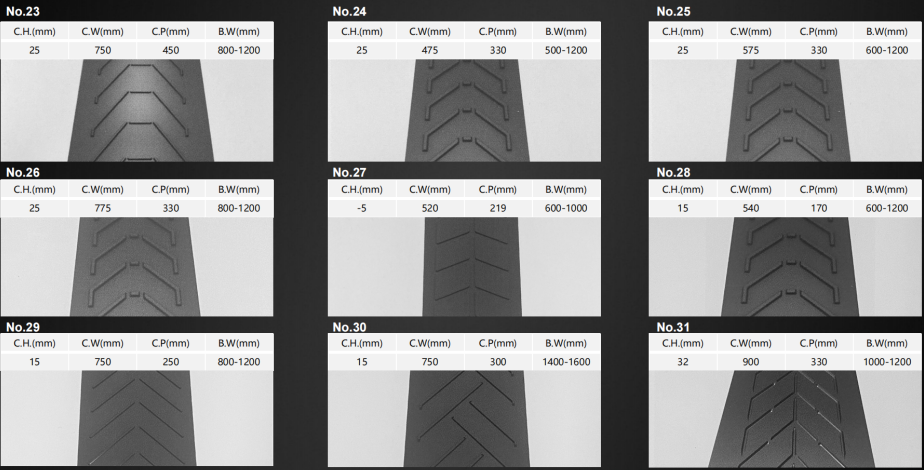

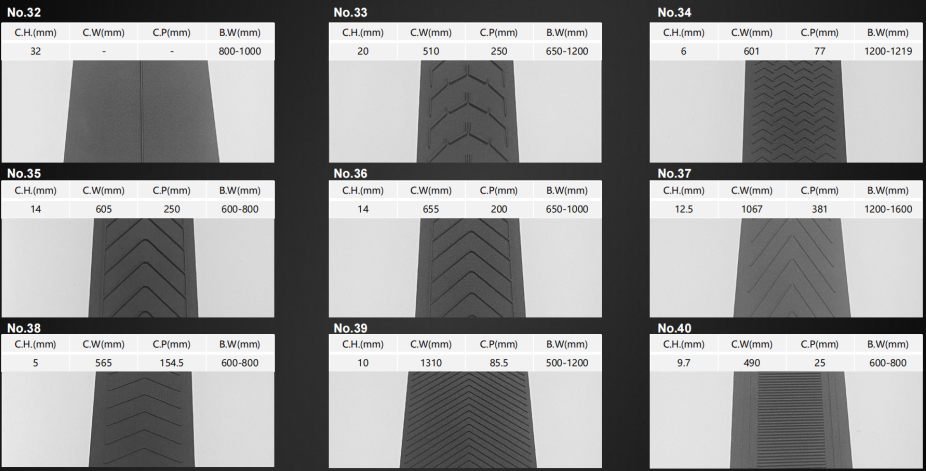

To accommodate diverse industrial requirements, chevron belts are available in a spectrum of pattern configurations, broadly categorized by their geometry and profile dimensions. The primary distinction lies between open-type patterns, which facilitate efficient cleaning and are ideal for cohesive or lumpy materials, and closed-type patterns, designed to prevent the seepage of fine, powdery substances. Each type is further offered in a range of profile heights—typically classified as high, medium, or low—allowing for precise selection based on the material's angle of repose and the conveyor's specific incline angle, which can extend up to 40 degrees or more in certain configurations.

This tailored design philosophy renders chevron belts exceptionally versatile in handling a vast array of materials, from free-flowing powders and granular aggregates like grain and plastic pellets to larger, irregular lumps such as mined ores and crushed stone. Their efficacy also extends to the transportation of unit loads, including sacks and boxes, by providing the critical grip needed to prevent downhill sliding. The principal benefits conferred by this technology are multifold: a significant enhancement in operational efficiency on steep gradients, a drastic reduction in material loss and spillage, and the opportunity for more compact plant layout design by reducing the conveyor's footprint. As such, chevron conveyor belts have established themselves as an indispensable component in sectors ranging from hard-rock mining and aggregate processing to agricultural logistics and automated warehouse systems, delivering a proven, cost-effective solution for the demanding task of inclined material conveyance.

Specifications

| Cover Rubber grade | 8MPA,10MPA,12MPA,15MPA 18MPA,20MPA,24MPA,26MPA | |

| Top+Bottom thickness | 3+1.5,4+2,4+1.5,4+3 | 3/16"+1/16",1/4"+1/16" |

| Belt thickness | 3mm,4mm,5mm,6mm,7mm,8mm,9mm,10mm,12mm,15mm,20mm,25mm | |

| Belt length | 10m,20m,50m,100m,200m,250m,300m,500m | |

| Belt edge type | moulded(sealed) edge or cut edge | |

| Belt width (mm) | 500,600,650,700,800,1000,12001400,1500,1800,2000,2200,2500 | 18",20",24",30",36",40",42"48",60",72",78",86",94" |

| Tensile strength | EP315/3,EP400/3,EP500/3,EP600/3 EP400/4,EP500/4,EP600/4EP500/5,EP1000/5,EP1250/5 EP600/6,EP1200/6 | |

Applications

Designed for steep-incline conveyance up to 40 degrees, this belt's unique corrugated surface securely contains materials, preventing rollback and spillage. It is the ideal solution for efficiently handling bulk materials like coal, sand, and gravel in mining, port, power, and construction industries.

Advantages

1. Outstanding large angle conveying function

2. Wide range of material applicability

3. Optimized space layout and significant energy saving benefits

4. Strong toughness and high reliability

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest