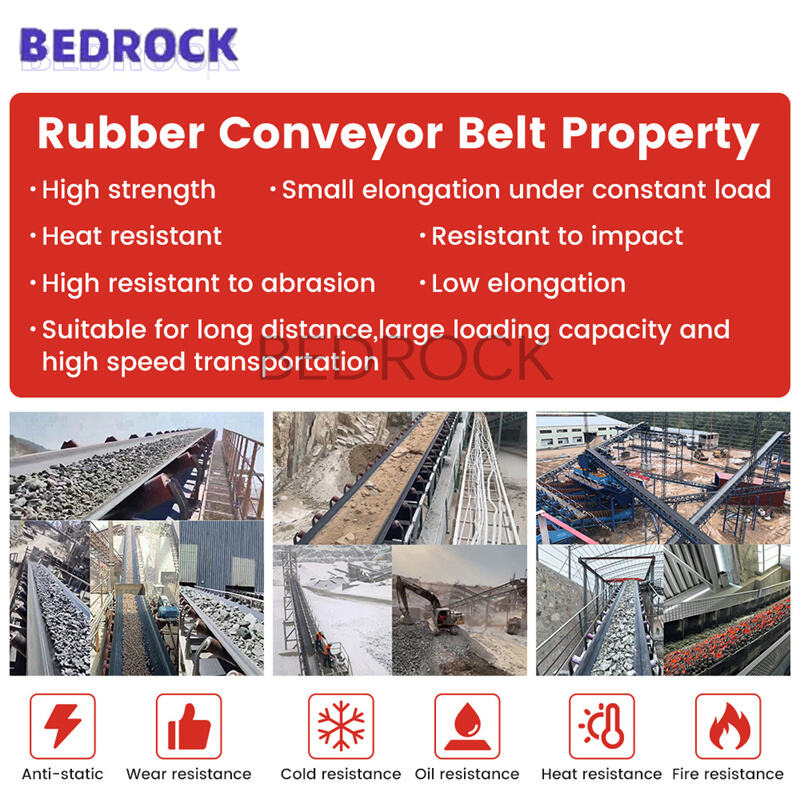

Custom Anti-Tear Polyester/Nylon Conveyor Belt for Quarry Crushing Line for Manufacturing Plant and Retail Industries

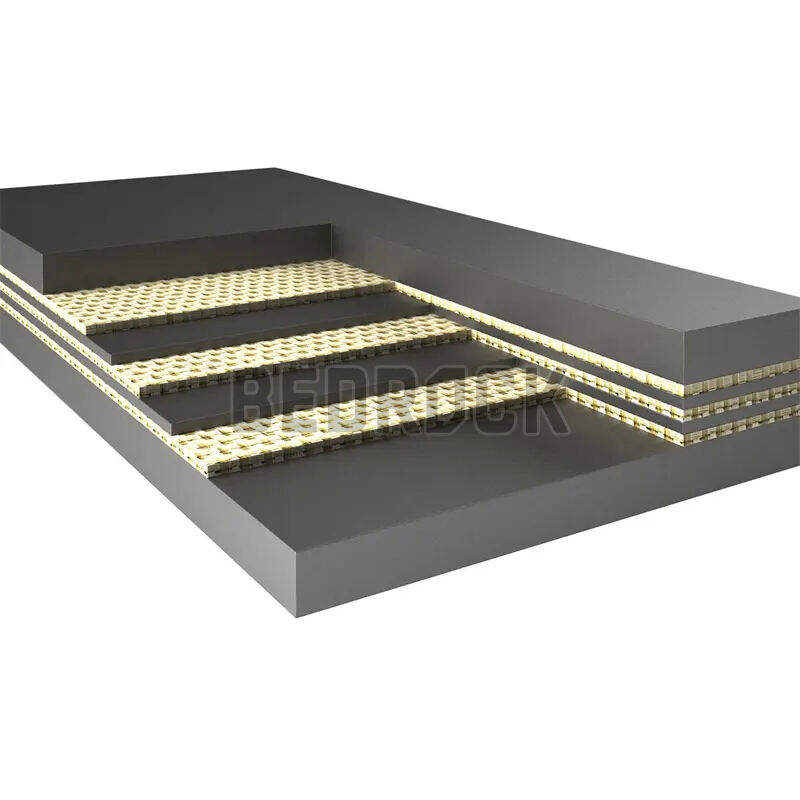

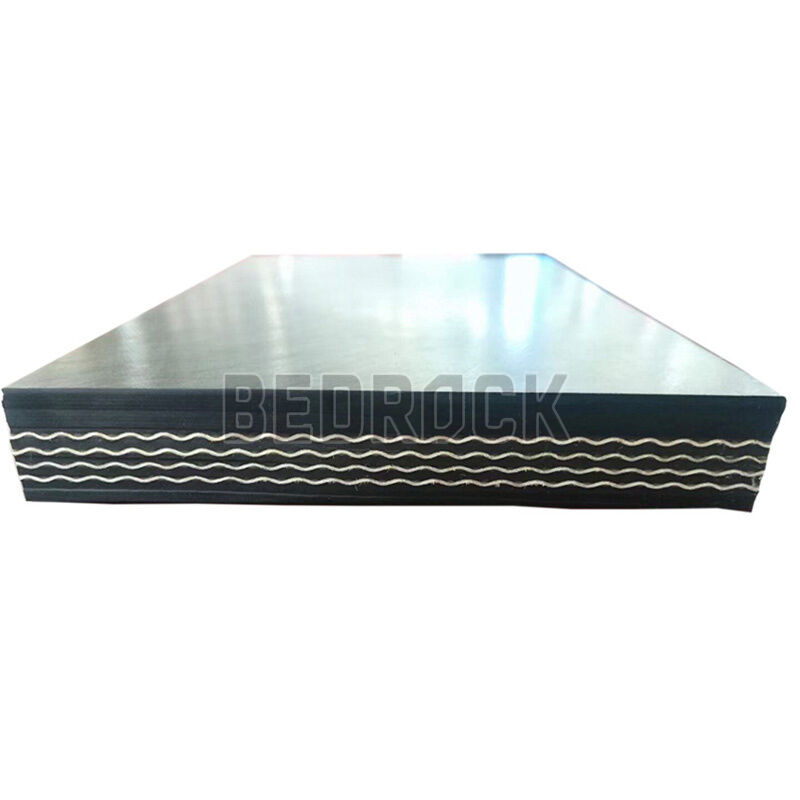

The conveyor belt is provided with transversely uniformly arranged high-extension steel wire ropes orhigh-strength and high-extension chemical fiber ropes on(or above and below)the steel wire rope coreor fabric core as the tear-resistant layer,and the tear-resistant layer is perpendicular to the runningdirection of the conveyor belt.When the conveyor belt transports hard and sharp materials,the anti-tearlayer can prevent the sharp and hard objects from being punctured.Once punctured,it can also generateenough resistance to resist the sharp and hard objects from tearing the tape,thus effectively preventingthe conveyor belt from tearing.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

Tear Alarm Protection System: During the normal operation of the conveyor belt, if external sharp objects penetrate or cause structural damage to the precisely embedded electromagnetic induction coil, the integrated monitoring system will immediately detect this abnormal condition. The coil's damage signal is rapidly transmitted through shielded cables to the central control console's processing unit, which analyzes the signal parameters and simultaneously activates two critical emergency responses: an immediate full-system emergency braking action to halt all mechanical movement, and the triggering of both visual strobe lights and audible sirens to alert on-site personnel about the belt tearing incident.

Belt Misalignment Alarm Mechanism: In the event that the conveyor belt experiences lateral displacement during operation due to mechanical imbalance or other factors, causing the positional relationship between the installed sensor coil and the fixed-position detector to exceed the safety threshold pre-programmed in the system (typically 5-10mm deviation range), the real-time monitoring circuit will capture this deviation. The system automatically converts this spatial displacement into an electrical signal that travels through industrial-grade communication lines to the central control console. Upon signal verification, the console executes a coordinated emergency protocol that includes activating the hydraulic braking system to safely stop belt movement while simultaneously illuminating warning indicators and sounding distinct alarm tones to notify maintenance teams about the misalignment condition.

Material Blockage Detection and Alarm System: When the conveyor system encounters material accumulation or jamming during transport operations, resulting in measurable speed abnormalities detected by the high-precision velocity sensors installed along the belt path, the sensor array immediately registers this operational anomaly. The detected speed variance data is processed by the onboard microprocessor and transmitted via the industrial network to the central control station. The station's intelligent analysis module evaluates the severity of blockage based on preset algorithms and initiates a comprehensive response sequence: first engaging the emergency stop mechanism to prevent equipment damage, then activating both flashing beacon lights and pulsating alarm horns to warn operators about the material flow obstruction situation, while also logging the incident details in the system's maintenance database for future reference.

Specifications

| Model | Level | Transportation inclination angle<20℃ | |||

| Tensile strength≥,N/mm | Elongation at break≥,% | ||||

| vertical | horizontal | vertical | horizontal | ||

| 680S | CET-4 | 680 | 265 | 15 | 18 |

| 800S | CET-5 | 800 | 280 | ||

| 1000S | CET-6 | 1000 | 300 | ||

| 1250S | CET-7 | 1250 | 350 | ||

| 1400S | CET-8 | 1400 | 350 | ||

| 1600S | CET-9 | 1600 | 400 | ||

Applications

This corveyor belt is suitable foruse in mining.docks,metalurgy,building materials,coal and otherplaces where sharp and hard objects are conveyed and the material drop height is large.

Advantages

1. Improve production efficiency and reduce downtime.

2. Reduce operating costs and minimize maintenance expenses.

3. Enhancing Security

4. Suitable for demanding operating conditions

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.