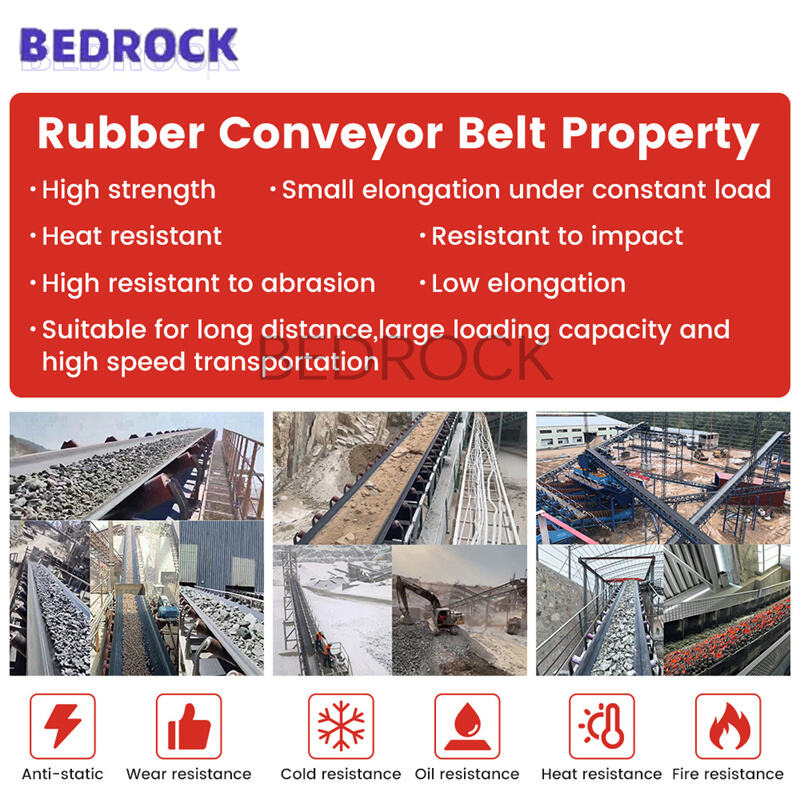

EP Flame Retardant Conveyor Belt Fire retardnt conveyor belt for Coal Mine and Manufacturing Plant

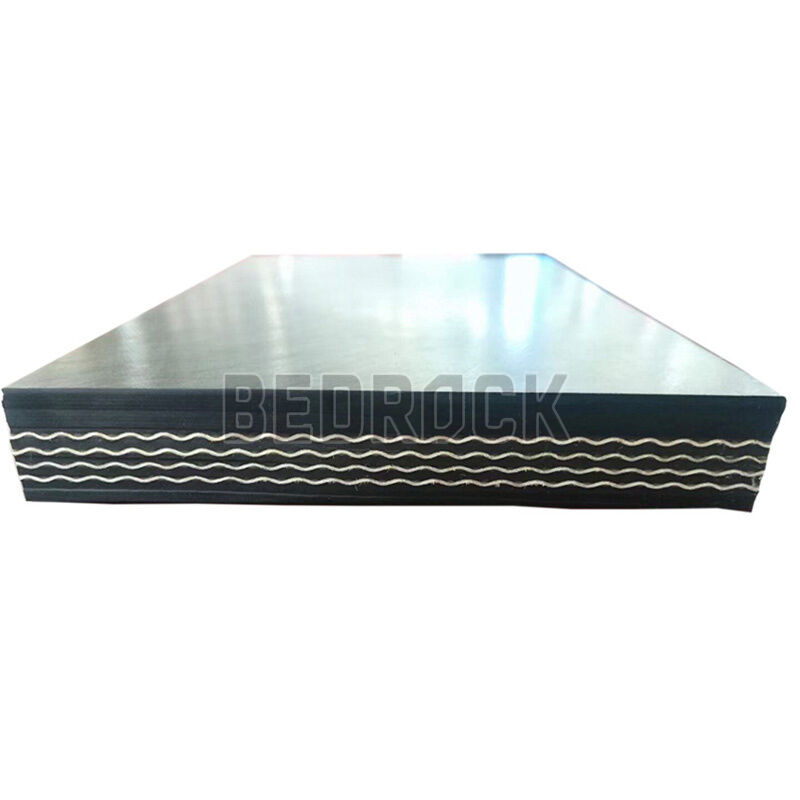

This product is meticulously manufactured from polyester canvas and nylon canvas through processes including calendering, molding, and vulcanization. It is suitable for conveying non-corrosive, non-sharp bulk materials such as coal, as well as granular and powdered substances, in flammable and explosive environments like coal mine shafts. It can also transport packaged goods.

A variety of mateials in the form of lumps,granules,and powders without spikes,such as coal and other bulk materials or finished items.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

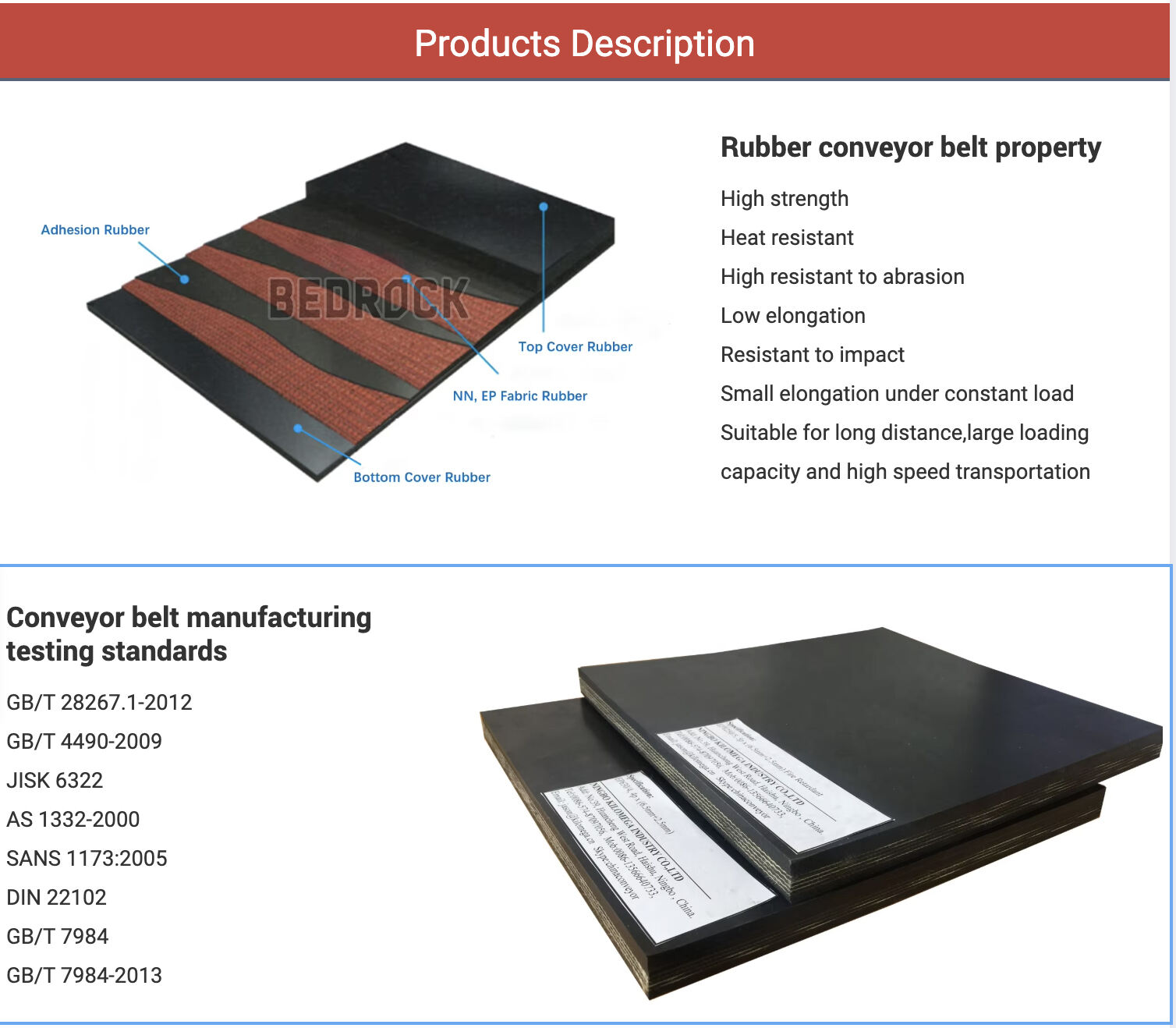

Description

Coating Performance

| Project | Unit | Level L | Level D |

| Tensile strength | Mpa | ≥14 | ≥18 |

| Elongation at break | % | ≥400 | ≥450 |

The performance of flame-retardant conveyor belt coverings directly determines their safety and durability in industrial transportation. First, the coverings must possess excellent flame-retardant properties to effectively suppress flame spread in high-temperature or open flame environments, thereby reducing fire risks. Second, they should demonstrate superior wear resistance to withstand frictional wear during prolonged material handling, extending the conveyor belt's service life. Additionally, the coverings need strong tear resistance to prevent damage from sharp materials or sudden tensile forces. Flexibility is equally crucial, as it requires maintaining appropriate elasticity across varying temperature conditions to adapt to complex operational environments. Finally, the coverings must exhibit chemical corrosion resistance to withstand erosion from acids, alkalis, and other chemicals, ensuring stable operation under special working conditions. These combined properties form the core competitiveness of flame-retardant conveyor belt coverings, providing reliable safeguards for industrial transportation.

Safety Performance

| Project | Flame retardancy rating | |

| K2 | K3 | |

| Flame duration | The total flame duration of six coated samples should not exceed 45 seconds, with no single sample exceeding 15 seconds. | The average flame duration of three coated samples should not exceed 60 seconds. |

| Static electricity discharge | ≤3*108Ω | |

| Reignite | No flame should reappear on any sample | |

The safety performance of flame-retardant conveyor belts extends beyond material fire resistance to encompass electrostatic dissipation, tear resistance, and stability in extreme environments. In high-intensity transportation scenarios, conveyor belts are prone to tearing from material impacts or foreign object entrapment. To enhance safety, these belts should utilize high-tensile materials and incorporate tear-resistant layers in structural design, thereby improving durability, extending service life, and reducing accident risks. To ensure safety, these belts must undergo specialized treatment to maintain non-softening properties under high temperatures, non-burning characteristics, and non-brittle performance under low temperatures, thereby ensuring stable equipment operation. According to industry standards, flame-retardant conveyor belts must meet specific flame retardancy ratings (e.g., UL94-V0 or GB/T standards). This requires the belts to rapidly self-extinguish upon flame contact without producing toxic gases or excessive smoke, minimizing hazards to personnel and the environment. The belts must also demonstrate sufficient tensile strength, wear resistance, and fatigue resistance to withstand prolonged high-load operations, preventing safety incidents caused by breakage or wear. Beyond fire resistance, conveyor belt materials must comply with environmental protection requirements, free from harmful substances (such as heavy metals or halogen compounds) to avoid threats to both the environment and human health during use or disposal. The safety performance of flame retardant conveyor belt needs to be comprehensively considered from many aspects, including material selection, structural design, process optimization and adaptability to the actual application scenario, so as to ensure its reliable operation under various complex working conditions and maximize the production safety.

Specifications

| Fabric specs | Ply thinkness s(mm/p) | Strength series | Cover thickness | Widt h(m m) | ||||||

| 2ply | 3ply | 4ply | 5ply | 6ply | Top | Bottom | ||||

| EP-80 | 0.6 | 160 | 240 | 320 | 400 | 480 | 2.0–8 | 0.4–5 | 400–2500 | |

| EP-100 | 0.75 | 200 | 300 | 400 | 500 | 600 | ||||

| EP-150 | 1.00 | 300 | 450 | 500 | 750 | 900 | 500–2500 | |||

| EP-200 | 1.10 | 400 | 600 | 750 | 1000 | 1200 | ||||

| EP-250 | 1.25 | 500 | 750 | 1000 | 1250 | 1500 | ||||

| EP-300 | 1.35 | 600 | 900 | 1200 | 1500 | 1800 | 800–2500 | |||

| EP-350 | 1.45 | -- | 1050 | 1400 | 1750 | 2100 | ||||

| EP-400 | 1.55 | -- | -- | 1600 | 2000 | 2400 | 100–2500 | |||

| EP-500 | 1.70 | -- | -- | 2000 | 2500 | 3000 | ||||

Applications

Flame-retardant conveyor belts are commonly employed in high-temperature or low-temperature environments such as metallurgical plants, mining operations, and cold storage facilities.

Advantages

1. Excellent flame-retardant properties

2. Meets the demands of harsh environments

3. Minimizes fire damage to production facilities, products, and surrounding areas

4. Long service life with superior safety performance

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.