Mining belt conveyors are an important part of the mining process used to transport both large and rugged materials from the underground to the surface. Those conveyor belt employ the use of belts running on rollers or rolls and are a convenient and relatively faster method to transport large volumes of bulk materials across long distances. Large quantities of material (ore and waste) are mined because these deposits form the basis for thousands of square feet of your mine, yet transporting materials by hand or truck can be a very slow and expensive process. That’s why mining belt conveyors are popular, whether you’re trying to move a few tons of material over a long distance or some other application. At BEDROCK we are dedicated to protecting our brand reputation and are as committed to the quality of our conveyor products as we are to that of our one-piece polyurethane wear products.

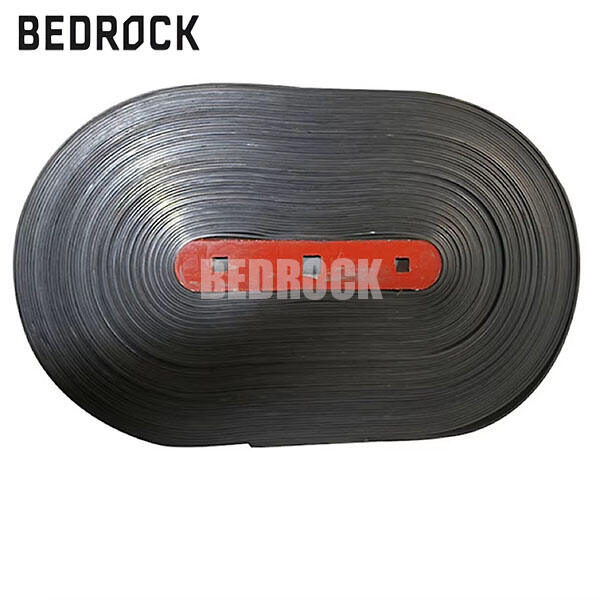

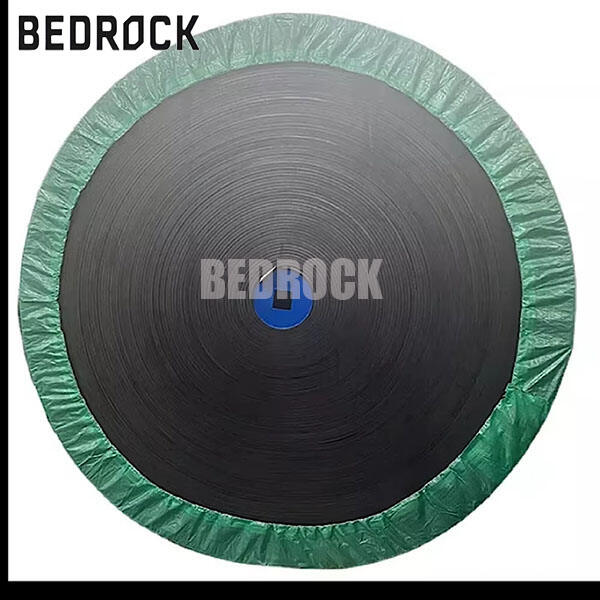

Mining belt conveyors are capable of operating heavy duty work even if under harsh conditions. These belts are fashioned from tough rubber or synthetic materials that wear well. It carries rock, ores or coal upon its bosom without shock or slip. The rollers and frames are made of sturdy steel; they can take the weight of your materials and maintain your supplies properly aligned. And, the conveyors can be very long often miles to connect different areas of a mine. This ability to carry loads for long distances without stopping is an enormous industry advantage. Some conveyor belts are equipped with cover s or cleaning devices to oppose dirt and damage or materials spills. When it comes to mining belt conveyors, their features and simple system handles them all well. That way they can be used on different sites, such as moving coal at a coal mine or crushed stone at a quarry. Quality, strength and long lasting conveyors translates into less down time and fewer repair costs, resulting in more money at the end of the day to keep the plant up and running on schedule. In addition, mining belt conveyors cut back inside trucks in mines which reduces fuel costs and minimizes pollution. It’s a recipe that can make sense when it comes to bulk material handling offering strength, efficiency and safety all in one machine.

When you purchase mining belt conveyor, finding a trustworthy manufacturer is very significant. Many buyers are looking for wholesale distributors to find good prices, but suppliers don't all offer the same helpful service or quality. At BEDROCK we are dedicated to creating strong customer relationships, and helping you with all your material handling needs for years to come. If you source from someone who knows mining challenges, the machines are designed for the task at hand, not merely belts. A trustworthy distributor will have a variety of conveyor sizes and configurations, allowing you to select the best one for your mine’s particular requirements. They also assist clients with installation assistance, spare parts and technical consultations. Sure there are some suppliers who will sell you cheap conveyors, but they do tend to break down regularly and mess up your optimisation. Instead, seek out the likes of companies such as BEDROCK that use only high-quality materials and offer expert engineering combined with real world testing to ensure their resistant belt hold up in harsh conditions. You can also have better warranty terms and faster delivery when you purchase wholesale from a reliable wholesaler. Another factor is to see if the supplier provides customized services, as mining sites have different layouts and material types. With BEDROCK, you have the flexibility to customize conveyors to your particular quarry. Such a service is rare and precious. Picking the best wholesale supplier can leave you with no surprises, good value and a mining operation that continues to run strong without any interruptions.

If you are in need of mining belt conveyor, it is advisable that you search for a place where you can find good quality machines at affordable prices. Belt conveyors are utilized to transport rock, coal or minerals in mining operation. The belt conveyors have to be very strong, and because mining is a dirty job, everything needs to be able to last. Of course, this is the reason that so many companies, particularly those who do any kind of mining work, prefer to buy the conveyor system they need from a company they buy home plan which will offer affordable prices. BEDROCK is a wholesaler that sells construction mining belt conveyor. When you buy wholesale, you'll have more conveyors being sold to you at a lower price by quantity. This makes it possible for mining operations to save money while acquiring high-quality machines. BEDROCK transfer conveyors are constructed of 12 ga. type 304 stainless steel, and have a rugged design suited for extremes in wet or dry environmental conditions. They also have clever designs for running their conveyor belts smoothly and not breaking down. When you purchase from BEDROCK you are not only buying a quality machine but the reassurance that we know machines inside and out – we will make sure to keep your bill low for service repairs! And in addition to bulk purchasing, with BEDROCK you’re able to purchase a high volume of conveyors at one time something that makes this practice particularly useful for mining operations. The company provides good service and consulting to chose suitable conveyor for your mine. In conclusion, for those looking to purchase sturdy and budget friendly minining belt conveyors, purchasing from BEDROCK on wholesale is the way to go! You get machines that perform what they are supposed to do, last forever and don’t cost much. This helps mining companies operate more efficiently and expand without having to make larger investments in new equipment.

Safety and longevity are two of the most important prerequisites in mining belt applications and as such, you can count on Transcor to provide enough belt strength and troughability to handle the toughest of jobs. These conveyors carry heavy loads, and anything wrong could lead to accidents or the work being stopped. Constant checks and maintenance are required to ensure the safety of the conveyor. First off, never overlook ensuring the conveyor belt is in good condition. Inspect for tears, cracks, or parts that are too worn to withstand operation. BEDROCK mining belt conveyors don’t need as much fixing as most other belts, which means all you really need to do is make sure they are working properly. The second stage is keeping the conveyor free of dirt, dust or anything else that could block it or damage it. If your machine runs smoothly, it is less likely to start fires or cause other dangers. Third, train workers well. All people who work around the conveyor need to be trained on how to operate this machine in a safe manner and also what procedures they should follow in an emergency situation. BEDROCK takes care of its customers with handouts and guides on how best to stay safe. Fourth, employ safety guards and emergency stop devices. These are devices that help stop the conveyor quickly if something goes wrong. All BEDROCK conveyors are built with safety in mind and included features that protect you, your employees and your equipment. To ensure your conveyor lasts, use it the way it is meant to be used. Do not overburden it or speed it up beyond its limit. Also, replace parts that are showing wear like chains or brake pads — before they cause more expensive problems. Oiling and maintenance on a regular basis keeps the parts moving well. The robust materials-based construction and intelligent design of BEDROCK’s conveyors enable them to outlast some brutal mining operations for decades. In conclusion, safety and durability are born from routine maintenance of equipment, excellent training and top quality gear such as BEDROCK mining belt conveyors. Why they really have to focus on doing these things, you know, is to protect workers and ensure machines remain running strong for any mining operation.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.