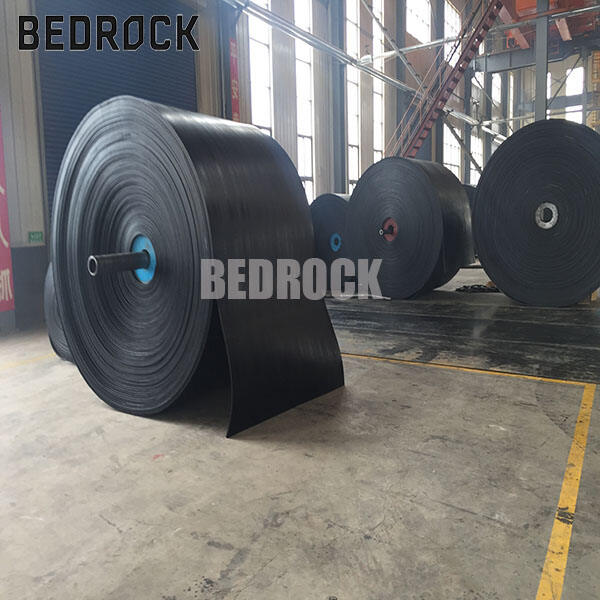

Purchasing in bulk is a wise idea for businesses that require rubber conveyor belts. There are ways for companies like yours to save money. At BEDROCK we have EXCELLENT prices for volume buyers. The more you buy, the less each belt costs. Meaning you can purchase high quality conveyor belts but don’t have to pay the price. That is, if you usually purchase a set of five belts, but then choose to buy 20 instead, the price for each belt may be much lower. Our sales team is available to illustrate and inform the best option for you. Colpitts: Buying in bulk also keeps all those belts in stock for your regular work needs. This is extremely effective when you have a lot of materials to get up and going. We’re here to discuss with you about what you need and to give a quote. We are proud of the fact that we are flexible and do whatever it takes to make deals work for you. Just a reminder, that when you purchase wholesale you are saving money and never have to worry about any interupptions in your business. You can concentrate on your work without fear of running out of belts.

Preventative maintenance can help alleviate these problems. “Basically you want to keep belts in sight,” Mays says. Inspect for any damages, like cracks or chipping. If you catch the problems early enough, you can often solve them before they become big problems. And make sure the belt is properly sized for whatever you’re moving. A belt that is too small for the load can slip. We also recommend here at BEDROCK good training for your employees. They can be expected to understand how best to load items on a belt and when it needs maintenance. It’s about team work, and knowing the equipment. By being diligent and proactive, you’ll keep your conveyor belts running smoothly for a long time, and be able to bypass many unnecessary problems.

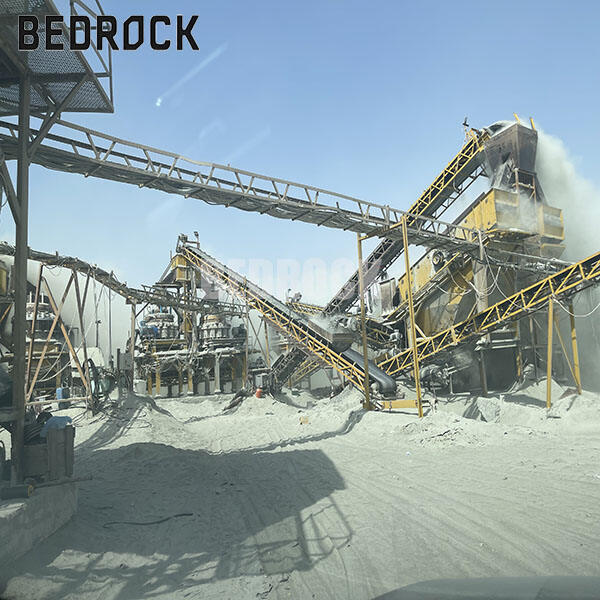

Rubber Belt Conveyors Rubber belt conveyors are quite a popular material handing solution for several materials in various industries. Just imagine working in a factory where boxes and heavy parts needed to be moved speedily and safely. Rather than carry each box by hand into a truck, workers can occupy rubber conveyor belts that move the stuff for them. The belts are both strong and flexible, enabling them to carry all sorts of materials, from heavy rocks on construction sites to small packages in stores. The reason you will like rubber conveyor belts is that they grip the items and keep them from slipping during transportation. It is particularly helpful in uneven floor conditions or when the belts are traveling uphill.

Another need for rubber conveyor belts is that they are capable of transferring heavy materials. Rubber is a powerful material, so these belts can carry heavy loads without breaking. This saves time and money for businesses, which can move shipments to their destination in greater quantities rather than sending them over in layers. In a mine, for instance, rubber conveyor belts are employed to take ores and minerals to the surface. Without the belts, it would have taken longer and more people to move the same amount of material. Even companies like BEDROCK know how useful these conveyor belts are, so the create premium rubber belts that they feel can meet their customers needs. It helps that rubber is also durable, which means these belts last a long time and businesses do not need to replace them as frequently, cutting down on waste and saving money.

Rubber Conveyor Belts Are Safe To Fit In addition to being tough and durable, the rubber material helps prevent accidents due to slipping as it provides much more grip. They are the most durable and safest for the environment, because they are manufactured from special materials that do not wear out. This means that when rubber conveyor belts finally wear out, they don’t do much damage to nature. Companies that outfit their workers with these belts can feel good about their choices, knowing they are being responsible while still getting the job done. In general, rubber conveyor belts help to greatly improve efficiency in material handling processes by accelerating and simplifying the movement of items. In many sectors they are an absolute necessity, without which the whole operation would grind to a halt - and that is where brands like BEDROCK come in.

When it comes to finding eco-friendly rubber conveyor belts, the key is to find certification that shows sustainable materials are used. This could mean recycled rubber or eco-friendly materials from companies that work to minimize their environmental footprint. In addition to certifications, there are other ways to verify that the company you’re purchasing from has a transparent supply chain and is producing its products soundly. That’s why BEDROCK prides themselves in selling conveyor belts that their customers can rely on and making certain each meets high environmental standards. And customers can feel proud of the fact that they are doing their part in contributing to a healthier planet when opting for eco-friendly products.

Yet another source of environmentally friendly rubber conveyor belts is to establish connections with those suppliers who specifically concentrate on recycling and putting again into use customers’ old conveyor belting. Businesses can call their local suppliers or look online for firms that sell green products. It can also help to visit trade shows or events related to the industry. At these events, companies frequently feature their new eco-friendly products which you can ask the manufacturers about. "Striking events such as this have a strong impact especially when well planned," says BEDROCK, which frequently gets involved in these to emphasize that they practice an environmentally responsible business.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.