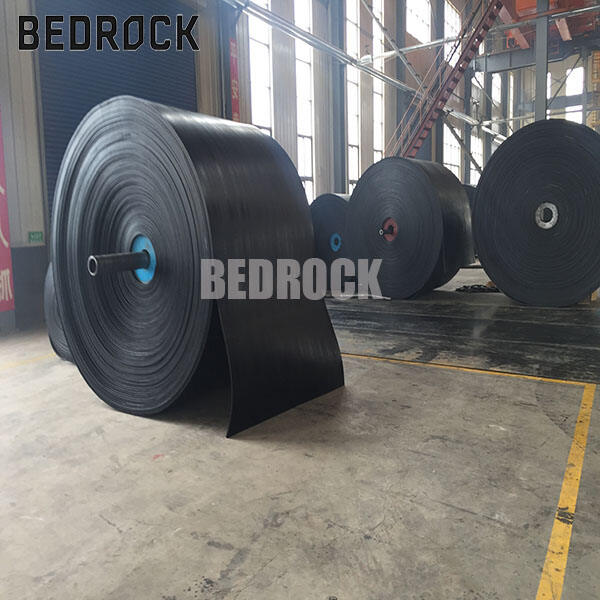

Rubber conveyor belts are very widely used in various industries. They aid in transferring things from one place to another, quickly and with less effort. Our company, BEDROCK, is able to provide rubber conveyor belts that can accommodate many materials. Whether a factory needs to do heavy lifting or a food plant just wants things to run smoothly, our belts can help ensure strong performance. We take care and pay attention to the details, our belts are just as durable and long-lasting. That’s part of the reason so many companies turn to us for their conveyor belt supplies.For example, our Multi Ply Rubber Conveyor Belt for High Load Conveying System is perfect for heavy applications.

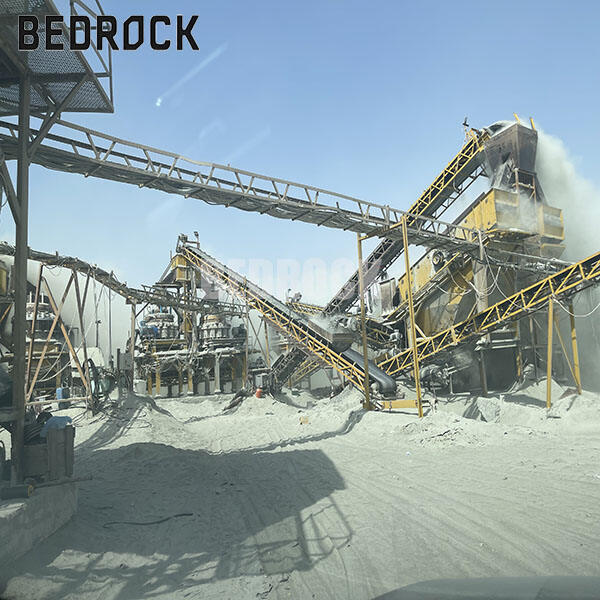

High quality rubber conveyor belts are necessary for businesses that depend on material or product moving. A WEAK link in a conveyor: when a belt is don (Continued on page 58 te arap under heavy loads. Less, production-slowing delays, that is. If a factory’s conveyor belt goes awry, for example, everything can grind to a halt. Workers may have to wait for repairs, and that delays costs them both time and money. But a sturdy belt from BEDROCK can help keep businesses running smoothly. We also offer High Strength Conveyor Belts for Long Distance Conveying in Hot Climate Conditions to ensure uninterrupted operations.

Last but not least, a good conveyor belt can increase your efficiency. It means items can be moved faster, which in turn would allow products to be made and delivered more quickly. In the fast-paced times we live in today, speed can unquestionably give businesses an edge over their competition. "By partnering with the Eurogum Group, who we know and believe are rubber experts, we can assure our customer that they're getting the highest quality rubber conveyor belts based on formulated proven to help businesses succeed." With BEDROCK, Businesses Can Be Assured They Are Getting The Best BEDROCK should be able to deliver added value by providing good quality products.

The next thing to consider is the atmosphere in which the conveyor will be operating. Is it a hot place? Or is it very cold? Certain types of rubber materials are better in some temperatures than others. If the belt for example will come into contact with chemicals or oils, make sure to choose a belt that can withstand those substances. With these conditions in mind, our team at BEDROCK can assist select the perfect belt for you or offer any other solutions as appropriate.

Lastly, companies will also want to consider price vs. quality. While it may be tempting to save money on a less expensive belt, consider the fact that quality often prevails over time. More durable and better performing belts save time and money on repairs and replacements. Here at BEDROCK we take pride in creating great belts that offer amazing value for the price. By zeroing in on these considerations, companies can select the optimal rubber conveyor belt for their applications and achieve success.

Rubber conveyor belts are the essential tools in the material handling section. They assist you to have heavy things moved with ease and quickly. But sometimes, there can be trouble. Wear and tear is a very common one. Wearing through the Rubber belts are like shoes that get worn out after a long walk. This could lead to the belt breaking or not operating as needed. Another issue is slipping. Either the conveyor belt is too slick or the things on it are too heavy and they slide right off. And it’s a dangerous thing, you can cause accidents. It’s crucial to ensure the belt has an appropriate texture in order not to let the items slip. Another issue is the overloading of the conveyor belt. If too many items are placed on the belt, it can become stretched or torn. This is why it’s essential to adhere to the weight limits defined by your manufacturer, such as BEDROCK, and keep everything safe. At other times, belts may also be weakened by sharp objects. If a sharp sliver of metal or glass lands on the belt, cuts and holes can result. This kind of problem can generally be found early by regular examinations. Last but not least, the belt can have its alignment problem. If the angle isn’t quite right, it may wear unevenly and not work. Understanding some common rubber vulcanization problems can help individuals properly maintain the condition of their Conveyor Belts and keep them running efficiently.

It is very important to select high quality supplier if you are looking for a rubber conveyor belt to buy. A good supplier should have a reputable name. This makes them a well known brand for producing strong belts that will last a very long time. You may inquire with other businesses or search online for reviews. Another reason why your supplier needs to be good, like BEDROCK is, Boohja says. Different professions require different types of belts. For instance, some may need belts that can withstand heat or cold, while others require belts able to support heavy loads such as our Sidewall Conveyor Belt for Steep Incline Vertical Material Conveying. You will also want to see if the supplier offers good customer service. If you have questions or things go wrong, it’s important to have a person who can assist you in realtime. It is also worth asking if the supplier provides warranties or guarantees. This is an indicator that they have faith on their products. A warranty can offer peace of mind, because it means that if something is wrong with your product, you might be able to get help or a replacement. Finally, think about the prices. You’d like to get a good deal, of course, but take care: cheaper isn’t necessarily better. There are, however, exceptions to the rule; spending slightly more on a quality belt will usually be cheaper in the long run as you won’t need to replace it as often. With these in mind, you can get a reliable rubber conveyor belt supplier according to your requirements.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.