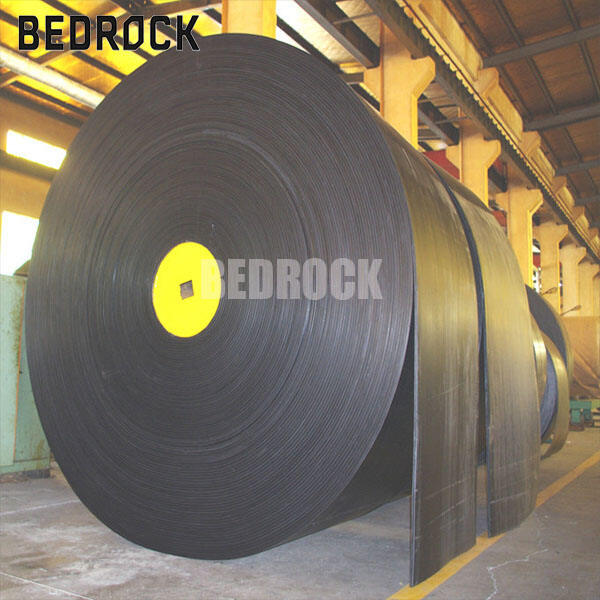

Rubber conveyor belts are quite essential in most of the places. They help transport heavy items, like coal, grain or packages, from one place to another. Factories and warehouses couldn’t work quickly and safely without good conveyor belt. The manufacturers that produce these belts need to be very careful when producing to ensure they come up with a strong material and an excellent design. BEDROCK is one such company that specializes in producing durable rubber conveyor belting. These belts need to function well on a daily basis, often in tough conditions such as rain, heat or dust. That’s why the choice of manufacturer makes a big difference. When those belts break or wear out prematurely, work can come to a halt and money can be lost. So it is in businesses’ interest to know about the various rubber conveyor belt manufacturers and what they offer.

It can be hard choosing a dependable rubber conveyor belt manufacturer, particularly when purchasing several at once. There is a lot to consider before making up your mind. The manufacturer’s experience The first thing you need to do is, check if the manufacturer has good experience. BEDROCK has been making Belts for years so they know what works best. Experience equal less mistakes and better product. Then, focus on the materials they use. Not all rubber is the same. Some low-quality belts are easily worn and torn from cheap rubber. The rubber is decent quality and holds up well to hard use. Also, consider what goes on in the factory. Do they test every belt? Does some kind of machine exist that can do belts properly? Using meticulous measures, BEDROCK’s factory insures that every belt is strong and safe. Another point is customer service. When making a bulk purchase, you want to talk to someone who responds quickly to questions and solves problems.

As a businessman, when you are in need of rubber conveyor belt, selecting the excellent manufacturer is very important. It is a known fact that having a good rubber conveyor belts manufacturer like BEDROCK for your products ensure that you can be certain of quality and smooth operation as well as safety. But what makes a supplier the right one? First, it is about experience. BEDROCK has had many years of experience in making rubber conveyor belts. This makes them conversant with what passes and does not in such matters. They put all of those result to good use in the belts that they manufacture. Second, what the materials are matters a lot. BEDROCK uses the finest rubber and studiest fabrics in their belts. These keep up the wear and tear, even when laden with large or sharp materials. Thirdly, good manufacturers are good listeners.

Rubber conveyor belts have to be strong and durable for several years. Companies like BEDROCK use unique processes that ensure their belts are not only tough but also perform well. First up, they pick the best raw materials. BEDROCK utilizes high-end rubber that is capable of withstanding the heat, cold, oil and other harsh elements. This helps the conveyor belt fabric endure harsh environments. Second, the type of belt also counts.

BEDROCK employs state-of-the-art machinery and tests belts in production to identify weak spots early. That way only the best belts make it out of the factory. Special finishes are applied to increase the surface quality of the belt. Some belts have additional layers of rubber to protect them from cuts, chemicals or rough materials, for example. That means the belt works as it should: even while loaded up with pointy or heavy stuff. Fifth, manufacturers put the belts to work in real or simulated workplace settings to see how they fare under pressure. BEDROCK does this to ensure that their belts can stand up to the daily rigors of many industries. Finally, good makers will give you instructions on using and maintaining the belts. BEDROCK gives cleaning advice, checks for damage and an indication of when to replace a belt. This helps customers ensure a long life and healthy operation of their conveyor belts. Throughout every step of the process, including engineering and design; longer belt life is achieved by managing specified tension during operation.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.