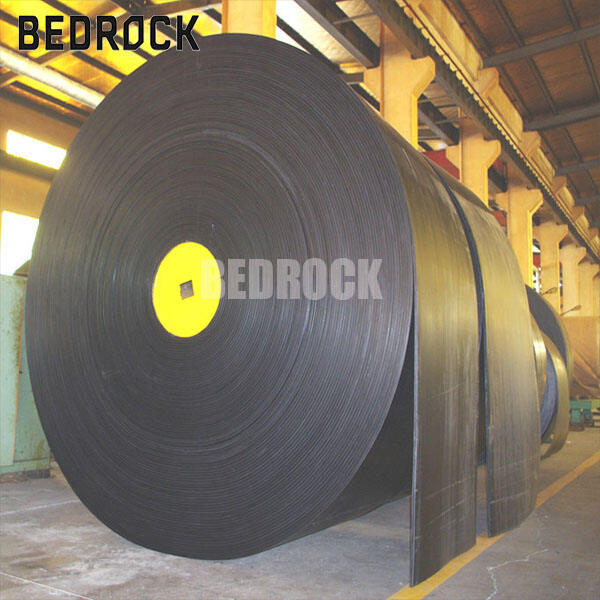

Rubber is material we see alot in different places, but it play very important role for conveyor belts. Conveyor belts they use in factories, mines and many industry to move stuff from one spot to another. Using rubber for these belts make them work much better. Rubber is strong, flexable and can handle various condition. In our company BEDROCK, we make sure our rubber have high quality, so conveyor belts can works good and last long time.

The way how rubber is made, its composition, is really key for how good conveyor belt perform. Different rubbers can mix with other stuff to become stronger or more bendy. For exemple, if use rubber that resist heat, it will be perfect for carrying hot items. On other hand, if rubber make for cold place, it stay tough even when freezing outside. This is why we offer a variety of conveyor belts, including heat-resistant conveyor belts and cold resistant conveyor belts.

Even rubber have many good thing for conveyor belts, there still some problem can happen. One big issue is wear and tear. When belt use alot, it start to breakdown. This happen quicker if rubber not suit for the job. For example if carry very heavy item but rubber not strong enough, it wear fast.

Rubber popular for conveyor belts because have many great quality. First it very strong and flexable. This mean can carry heavy load without breaking. When factory or warehouse move thing around, need material handle weight but still bend and stretch. Rubber do that! It adapt to different shape and size, important for various item. Besides strong, rubber also have good grip. This keep item from slip off while moving. Imagine carry stack of book without drop, you need grip! Rubber help with that.

Another reason rubber best is resist wear and tear. Belts use all day every day, get damage from constant use. Rubber handle this pressure and last longer than other material. Company save money because not replace belt so often. Also rubber withstand different temperature and condition. Hot, cold or wet, it keep working well. This make great for food processing, mining, construction. BEDROCK know importance of high-quality rubber for conveyor belts. Our product design to meet need of industry, make sure conveyor system run smooth and efficient every day. We also provide sidewall conveyor belts to help with specific handling needs.

Also use right kind rubber for job. Different industry have different need, choose correct type make big difference. Some rubber resist chemical, other for high temp. BEDROCK offer variety option to meet industry need, so our belts durable and effective. Finally right installation technique crucial. If not install proper, problem come later. Best follow manufacturer instruction careful, and if need hire pro to help. This ensure belt work as should and last long.

Finding eco-friendly rubber for conveyor belts become more important as people care about environment. Eco rubber make from natural or recycle product, help reduce waste and pollution. One best place is company specialize in sustainable stuff. BEDROCK committed provide high-quality eco option for customer. We choose material better for planet, so customer feel good about choice.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.