It gets rocks and ores from one place to another, making processing easier and quicker. This includes high quality steel cord rubber conveyor belting are strong and durable. BEDROCK Companies such as BEDROCK manufacture very high end rubber conveyor belts which they use almost exclusively in-situ at their mining operation facilities.

They have the ability to be flexible and navigate around corners, tight spots which is especially useful in mines as the site layout can evolve over time. This flexibility is beneficial in facilitating movement of materials in various directions. Another reason is the diversity of materials a sidewall conveyor rubber belt can transport. From wet dirt to sharp rocks, these belts can hold everything. In mining, this can be very useful, because the material being moved can vary greatly. In addition, rubber belts are known for their traction. This means the materials stay in place on a belt moving along at a steady clip, and spills and accidents aren’t likely. Safety is a concern in any mining operation, and the Conveyor Belt will keep employees safe: because when workers are working with, near, or around machinery that is heavy and powerful they can be injured by it.

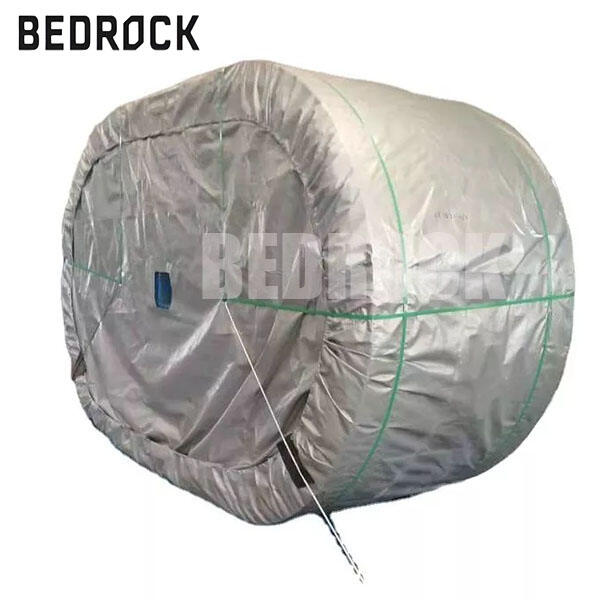

These providers often carry samples and are able to assist you with selecting the proper belt for your mining business. If you’re part of a mining operation, talk to your team about what you’ll need. They can even help you choose the best type of belt for the materials you work with. You can also go to mining trade shows. Such events typically feature a variety of companies displaying their products, such as BEDROCK’s rubber conveyor belts. It’s a brilliant opportunity to not only see the belts close up but also talk directly to the team of experts. getting High quality steel cord rubber conveyor belt is not a difficult task. When you need quality equipment to keep your operation running smoothly, you can get the most reputable products on the market at BEDROCK.

The wear resistant ep200 rubber conveyor belt can change if it rains a lot or if it’s too hot. This can degrade the belt so it is not as effective. To address these issues, companies such as BEDROCK need to pay close attention to how belts are used. Regular inspection and maintenance can also help you catch problems before they become big ones. It is also imperative to properly train your employees on how to use the belts. By taking these steps, your mining facilities can operate more smoothly and won’t need to deal with any delays that don’t absolutely have to happen.

The second thing is the fact that rubber conveyor belting can be very useful for mining, as it allows materials to move quickly and safely. In the mining industry, there is plenty of heavy material rocks and minerals which needs to be transported from one place to another. The reinforced rubber belting are strong enough to transport these heavy materials. They’re crafted from special rubber, designed to withstand the toughest conditions, including heat and heavy weight. That means they can work in mines where other kinds of belts would quickly break, or wear out. Another thing that makes rubber conveyor belting so important is because it also saves time.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.