Sand transport machine is a wonderful thing among the great things that enable sand to move from one place to another. These are the conveyor belts that people use when they want to move sand quickly and at a safe distance. The content of the frames run approximately as does a belt in reference to its sand load carried thereon. It is a great saving of time and energy that would otherwise be spent on human labor or trucks

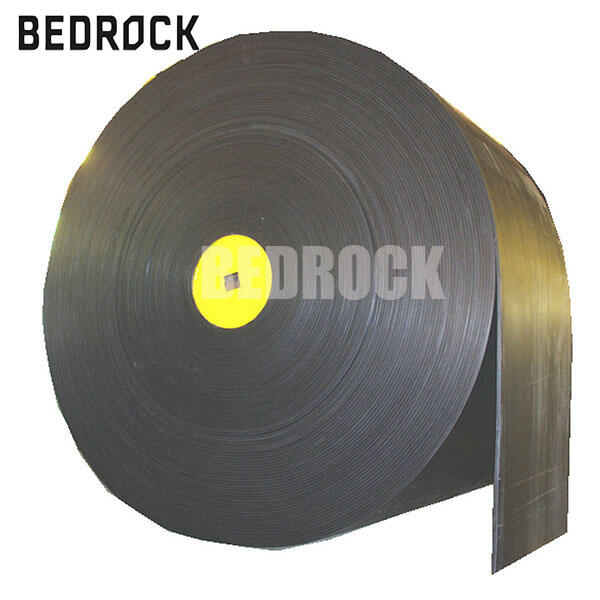

BEDROCK produces a tough and durable conveyor belt that is strong enough to be used even in difficult situations, like sandy beaches or a rough desert environment. These are heavy-duty belts built to carry loads and keep working, even when they don’t break down so easily. Through the use of a sand conveyor belt, the job can be accomplished in less time and less energy, as the workers are freed from the heavy lifting, thus a safer working environment is created.

Good conveyor belts for sand may not be easy to come across. You surely want to have belts that will live long without tearing or breaking in any way. BEDROCK delivers heavy duty belts for you to be able to carry loads of sand without any problem. The search of belts to buy in bulk should make you think of the need for a supplier who understands your needs. Besides, belts can be cheap-looking in addition to falling apart, thus costing more over all for blood. We TEST each belt for STRENGTH & DURABILITY – therefore you are going to be equipped when that old machine fails

From a large volume of belts, as they can manufacture, and with no waste of materials, it is also possible to get good rates. A great price combined with belts which are the perfect fit for your machines is what you will get if you buy from BEDROCK! For example, some of his customers had to have belts performing in the hot, dry areas where the sand was coarse and dusty. BEDROCK fabricated especially concrete conveyor systems with extra layers to stop the wear. However, there were other customers who were looking for belts that wouldn't slip if they got wet. We put better grip on the belts for them. It is clear from this example that BEDROCK communicates with different needs and provides a solution for each of them.

There are times when sand conveyor belts are accompanied by issues that make them less than a laughing matter. Such issues are at times the reason for the belts being slowed down or even stopped. A very frequent issue of such kind is a belt slipping. As an example, sand being wet or sticky may cause the belt to slip on the rollers. It is in fact the belt that is promptly worn out when it is slipped, and the energy is lost too. Heat resistant conveyor belt of BEDROCK has a surface that gives more grip, but anyhow, belt and roller cleaning will still be required quite frequently. Another problem arises when the belt is torn or cut. Sand is harsh on the edges, and the belt will be damaged if there is a sharp object or rock. BEDROCK, in solving the problem, suggests the use of belts that have thicker layers or are made of special cut-resistant materials. In addition to that, you may install metal detectors or magnets before the sand is delivered to the belt to get rid of the sharp objects that way

At times the belt goes off track or mis-tracking is the expression that is used for this case. The word "mis-tracking" refers to the belt moving to one side and, therefore, rubbing against the frame, which causes injuries. To prevent this problem, BEDROCK, through different programs and activities, imparts knowledge and skills to workers so that they can be competent in the right way of adjusting the belt and rollers.

In case your conveyor belts are the ones that are carrying sand, it is extremely important that you dedicate some time to proper handling. Conveyor belts are the ones that deliver sand to a particular place, while the big machines are the ones that do the heavy work at, for example, a construction site or a factory. If the belt breaks or gets worn out even if only slightly, your work will be delayed, and the repair or replacement will cost you a lot of money

To be able to keep a conveyor belt in the best possible condition, regular maintenance of the belt is a must. The most important thing is that you have to inspect the belt daily for any obvious damages such as rips, cracks or areas where the belt is worn out. Any parts that are in bad condition should be fixed immediately to stop further damage. In addition to that, she also mentioned that the belt should be cleaned regularly since sand and dust that are left will make the belt movement more difficult. One can safely clean the belt by using gentle brushes or an air blower, which is BEDROCK's suggestion. This way, the dirt is removed without the belt being harmed.

If changing sand is your everyday work routine, then purchasing conveyor hosing in bulk might be a more suitable way for you to go. These belts are constructed to be tough and long-lasting to be able to take heavy sand loads without tearing or being replaced within a short period of time again. Bulk buying means you have a large number of belts at once — usually for a lower price and also that you can have spare belts locally when a replacement is needed. We are very enthusiastic about purchasing from BEDROCK because they are committed to manufacturing the best sand transportation conveyor belts. BEDROCK belts, being so strong that they can be used practically in any environment like mines and construction sites, are made with durability as the first and foremost intention.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.