What are mining belts? They are used to transport rocks, coal, and other substances from place to place. These belts need to be durable: They bear heavy loads and operate in harsh conditions. A quality mining belt conveyor will continue to drag, run and pulls machines without stopping. BEDROCK creates mining belts designed for the harsh and intensive conditions of everyday use. They chew through wear and tear, however they’re the dependable choice if your working environment requires one to operate machines smoothly and safely.

Mining belts suppliers, but it is also important in the kind of work you will have. Great supplier provides belts -- just right for whats needed and delivers on time. BEDROCK provides the support that mining companies need from suppliers. They supply the belts which pass through quality controls and bring good customer service. We believe in fostering close relationships with users, so we assist in response to questions and technical support whenever you need. Another important point is price. Low-cost belts may seem like a money saver at first, but they can prove more expensive if they break frequently or wear out quickly. BEDROCK’s belt mining is built for reliability and fast response to keep you up and running. When it comes to choosing a supplier, you need to consider the quality grade, price, delivery time and support. It’s worth it in terms of reduced downtime and safer working conditions. This isn’t something to rush into, so take your time finding a supplier that you trust for all of your mining belt needs

Carrying the right tools can make any job easier and more efficient, but when all of those tools need to be transported across a worksite or mine it can be troublesome. When we say mining belts operating in brutal mining settings, we are referring to locations that are tough and hard. These locations can be extremely hot or cold, wet or dry and filled with dust and dirt. For a mining belt to be effective in this tough environment, it must be durable, safe and long-lasting.

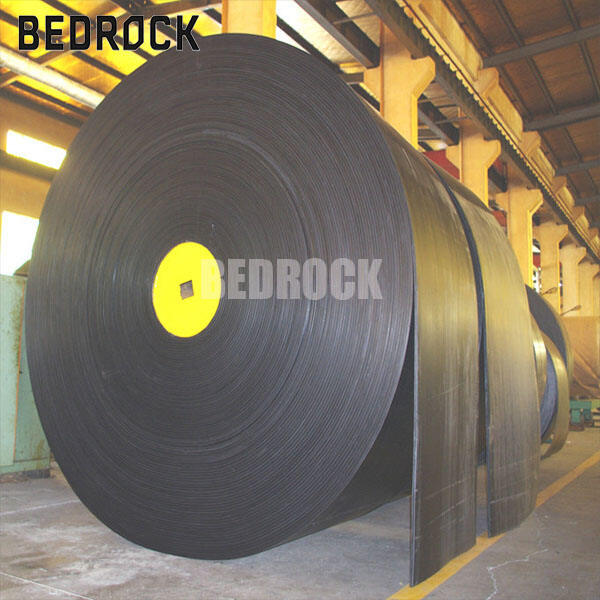

Another important feature that makes a mining belt tough enough for the hard places are what they are made of. What doesn’t break readily is reinforced by the strong materials via the BEDROCK's mining belts. These are tear, stretch, and wear resistant materials. This is a great feature as mining belts typically carry heavy loads; these could potentially damage lesser belts. Add to that the need for the belt surface to be rough or textured enough that it can hold onto minerals without their slipping, even if water gets on the belt or dust covers its surface.

For one, they pay less per belt because purchasing in bulk is more cost-effective. This is to help mining companies keep their costs low, which is so important in mining because a mine can be really expensive to operate. Second, a large stock of belts at hand enables the mine to keep operating without waiting for fresh belt to arrive. If a belt breaks, workers can readily swap in one of their spares. That means less downtime and more work every day.

While doing all of that work, mining belts can get damaged or develop defects. Defects include issues such as tears, holes or worn spots that can cause the belt to cease functioning properly. If mining firms don’t notice these defects early, conveyor belt can snap and lead to delays and expensive repairs. This is why it’s so important that we take a look at mining belts regularly and address problems immediately.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.