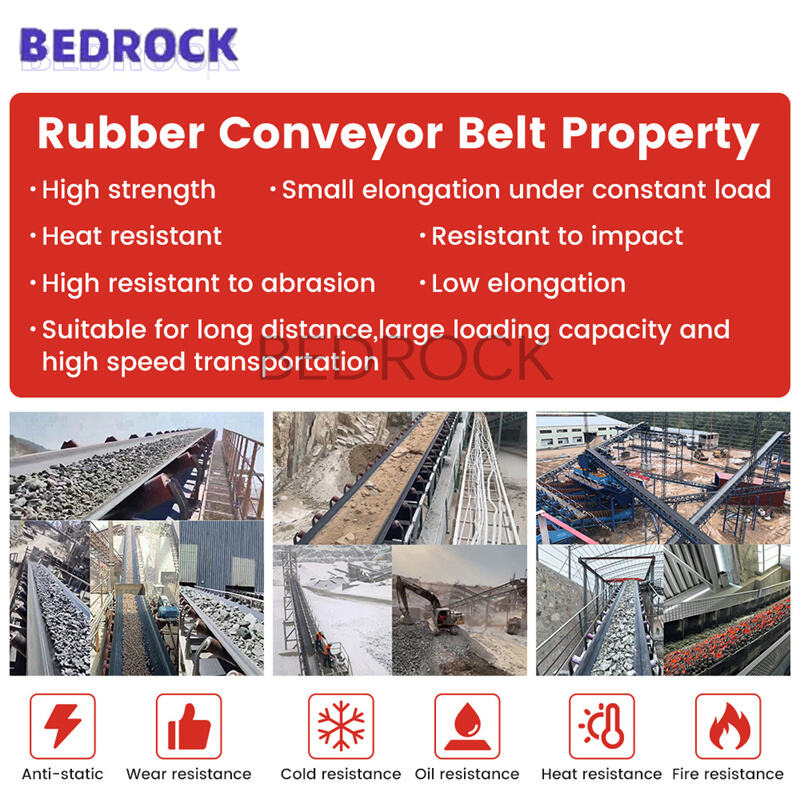

Manufacturer-Designed Oil-Resistant Conveyor Belts Adjustable Speed New

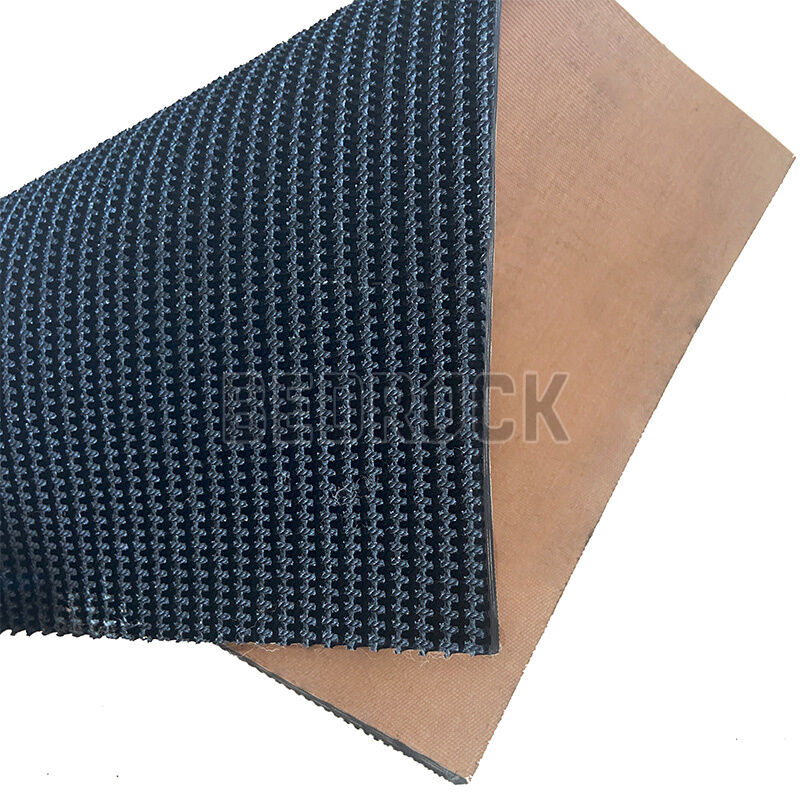

Oil-resistant conveyor belts are made of nylon canvas and polyester canvas through processes such as calendering,moldingand ulcanization.They have relatively good oil resistance and aresuitable for conveying oil-containing materials,as well as in somesituations where oily and chemical solvents may occur.Specificvolume changes occur.It has the advantages of low efficiency,high strength and wide range of use.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

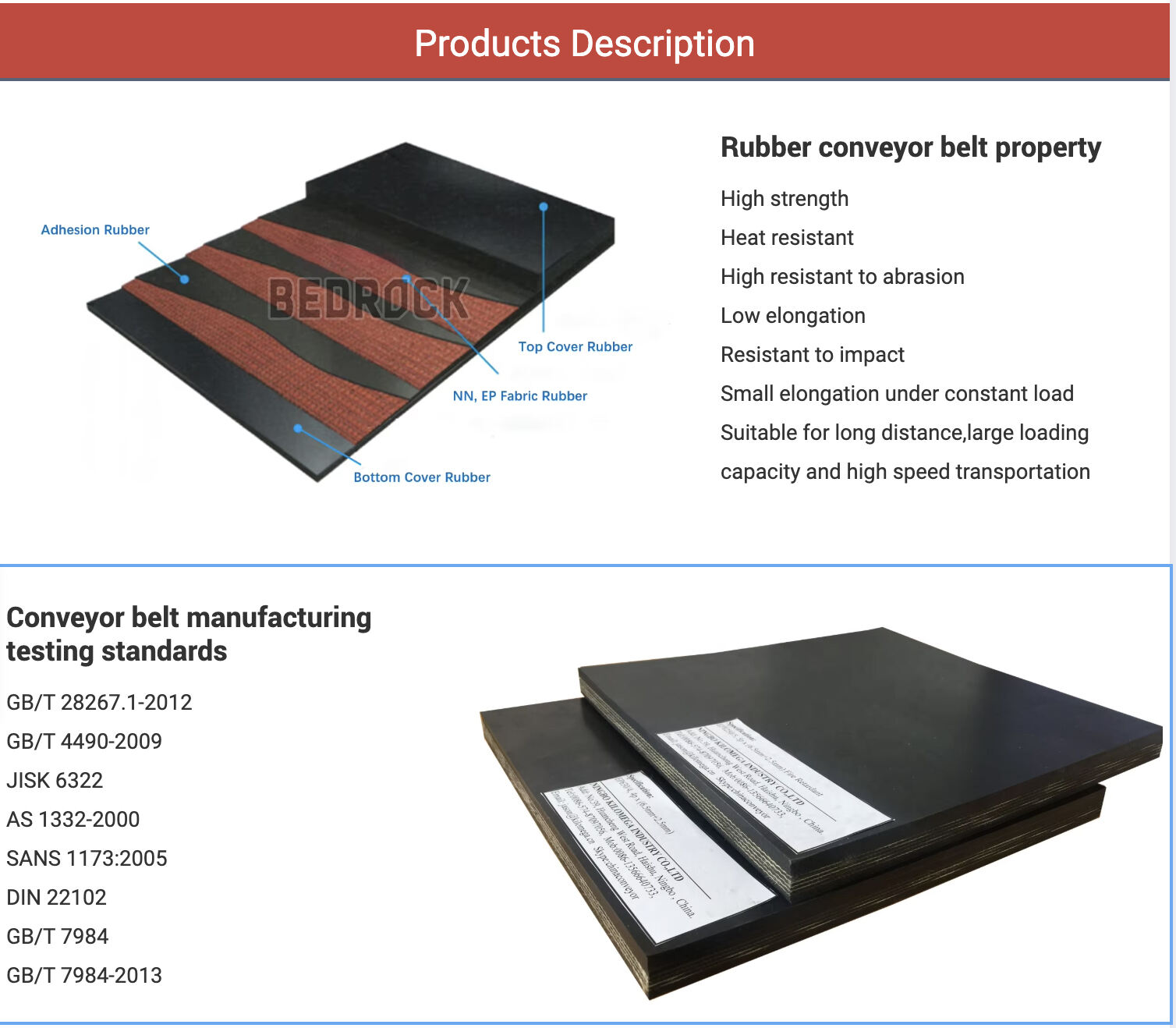

Description

In various industrial settings, these conveyor belts can effectively prevent oil penetration which might otherwise lead to material degradation or reduced service life.In chemical manufacturing facilities, they offer reliable transportation of materials even when exposed to aggressive substances.

The low volume change rate ensures that the belt dimensions remain stable despite prolonged contact with oils. This characteristic is crucial for maintaining consistent operational efficiency and preventing issues such as misalignment or slippage during use. High strength retention further enhances the durability of the belts, allowing them to withstand heavy loads without significant wear or deformation.

Moreover, the broad application scope of oil - resistant conveyor belts extends to mining, agriculture, and logistics sectors. In mining operations involving oily ores or lubricants, these belts provide a dependable solution for material handling. Within the agricultural domain, they facilitate the smooth transport of oil - rich crops or by - products. And in logistics centers dealing with packaged goods that may contain oils, the belts ensure seamless movement along assembly lines while safeguarding product quality throughout the process.

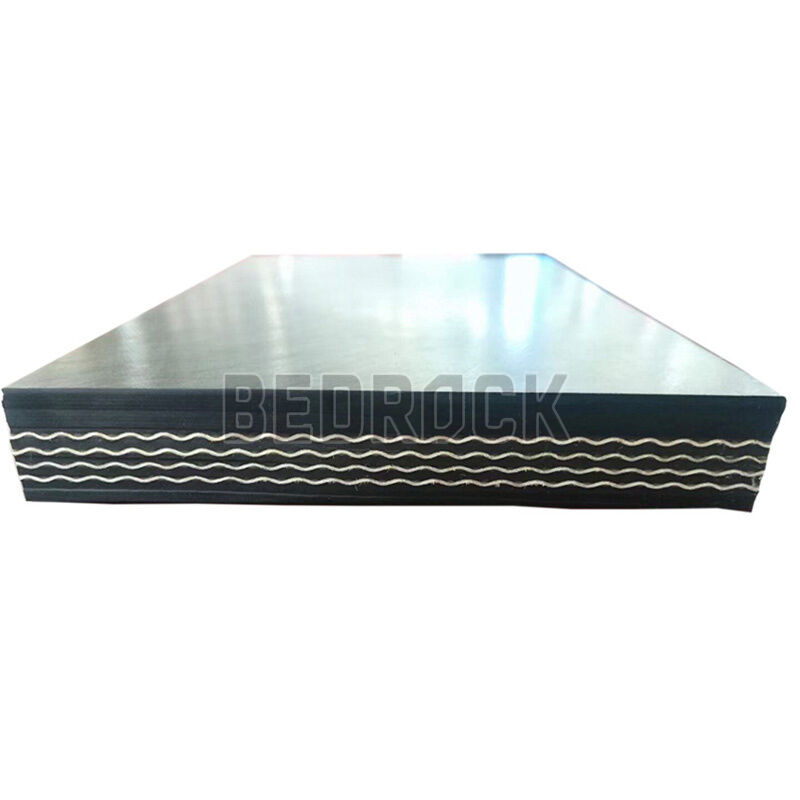

Technical Specifications 1. Oil-resistant conveyor belts are classified into two types based on the performance of the covering rubber: wear-resistant (D) and standard (L). The oil resistance is rated at two levels: Y1 and Y2.

Specifications

| Fabric specs | Ply thickness (mm/p) | Strength series | Cover thickness | Widt h(m m) | ||||||

| 2ply | 3ply | 4ply | 5ply | 6ply | Top | Bottom | ||||

| NN-100 | 0.75 | 200 | 300 | 400 | 500 | 600 | 1.5–8 | 0–4.5 | 400–2500 | |

| NN-150 | 0.80 | 300 | 450 | 600 | 750 | 900 | 500–2500 | |||

| NN-200 | 0.90 | 400 | 600 | 800 | 1000 | 1200 | ||||

| NN-250 | 1.15 | 500 | 750 | 1000 | 1250 | 1500 | ||||

| NN-300 | 1.25 | -- | 900 | 1200 | 1500 | 1800 | 100–2500 | |||

| NN-400 | 1.45 | -- | -- | 1600 | 2000 | 2400 | ||||

| NN-500 | 1.55 | -- | -- | 2000 | 2500 | 3000 | ||||

Applications

Oil-resistant conveyor belts are suitable for petrochemical applications (crude oil extraction, refining, chemical production), rubber tire manufacturing (compounding, molding, vulcanization), and port terminals (bulk cargo, oil product handling). They resist oil corrosion, ensuring stable material conveyance, equipment durability, and production hygiene and safety.

Advantages

1. Effectively resists corrosion from various oils

2. Combines high abrasion resistance with tensile strength

3. Smooth surface resists dirt buildup

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.