Rubber Rough Top Conveyor Belt

The Rough Top conveyor belt is designed for transporting lightweight materials such as bags, boxes, and packages at 35-degree inclines. Its rubberized top cover provides wear-resistant and anti-slip performance, delivering cushioning, shock absorption, and stable operation—particularly effective in preventing material slippage.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

The Rough Top conveyor belt is an industrial transportation solution designed based on tribological principles. Its specially treated anti-slip surface significantly enhances material handling efficiency. This product demonstrates excellent adaptability under various inclined working conditions, effectively resolving industry pain points such as material slippage and rolling that plague traditional smooth-surfaced conveyor belts.

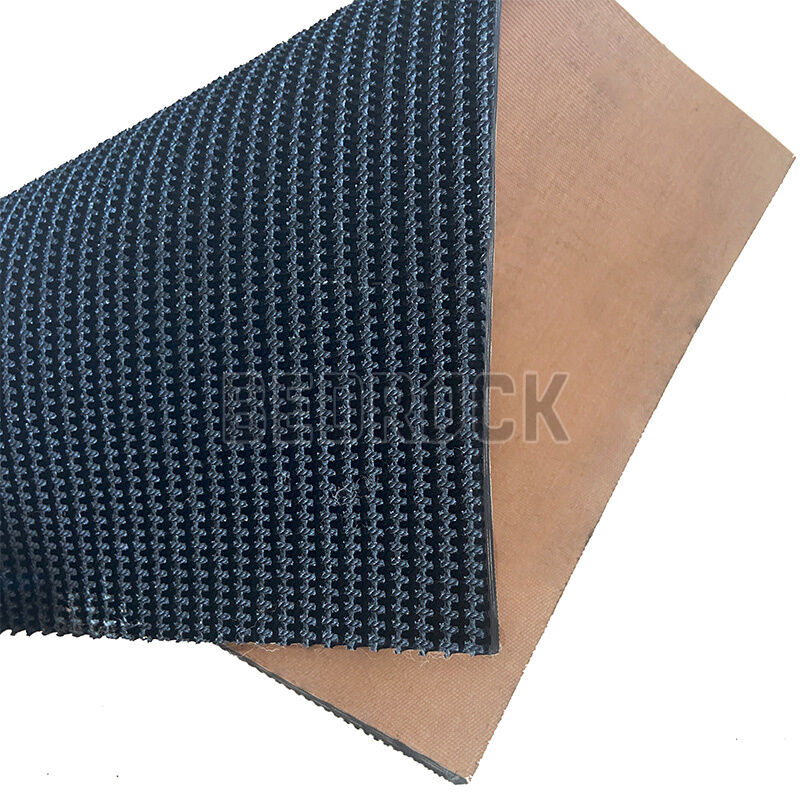

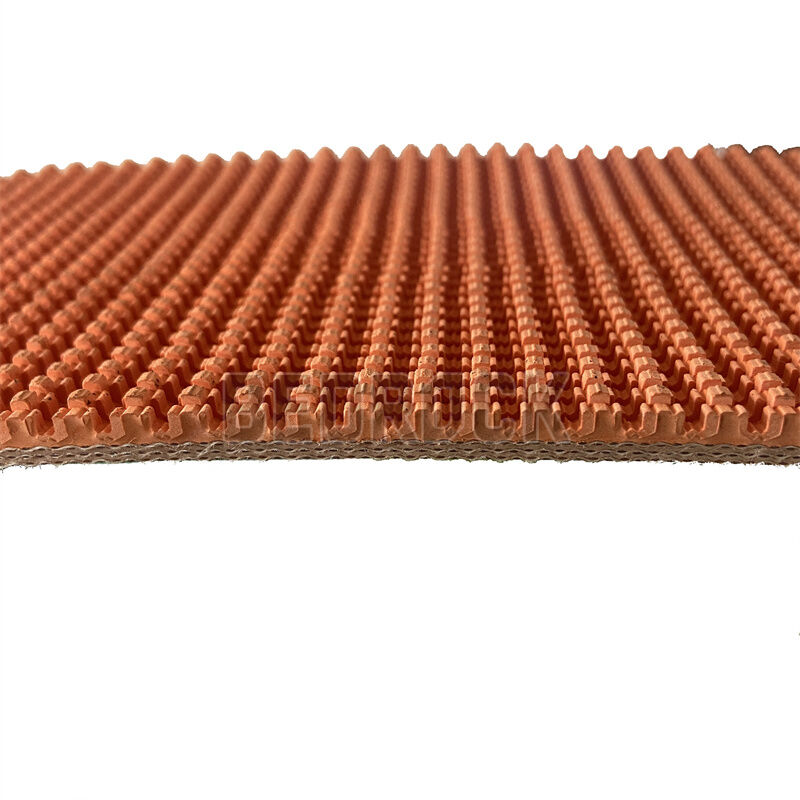

Structural Features:

1. The anti-slip surface layer employs either compression molding or specialized coating technology to create a uniformly textured raised pattern on the conveyor belt's working surface. This design achieves a 40%+ improvement in surface friction coefficient compared to conventional belts, while maintaining rubber hardness within the optimal range of 65±5 Shore A.

2. Reinforcement Layer: The skeleton layer is reinforced with high-strength polyester canvas EP100-EP600 or steel wire rope ST630-ST3500. These materials, after special adhesive treatment, exhibit excellent dimensional stability and fatigue resistance.

3. The bottom cover glue of the bottom protective layer adopts a low friction coefficient formula to effectively reduce the running resistance with the roller, and has excellent anti-tear and wear resistance characteristics.

Specifications

| Cover Rubber grade | 8MPA,10MPA,12MPA,15MPA 18MPA,20MPA,24MPA,26MPA | |

| Top+Bottom thickness | 3+1.5,4+2,4+1.5,4+3 | 3/16"+1/16",1/4"+1/16" |

| Belt thickness | 3mm,4mm,5mm,6mm,7mm,8mm,9mm,10mm,12mm,15mm,20mm,25mm | |

| Belt length | 10m,20m,50m,100m,200m,250m,300m,500m | |

| Belt edge type | moulded(sealed) edge or cut edge | |

| Belt width (mm) | 500,600,650,700,800,1000,12001400,1500,1800,2000,2200,2500 | 18",20",24",30",36",40",42"48",60",72",78",86",94" |

| Tensile strength | EP315/3,EP400/3,EP500/3,EP600/3 EP400/4,EP500/4,EP600/4EP500/5,EP1000/5,EP1250/5 EP600/6,EP1200/6 | |

Applications

Mining: inclined conveying of various ores and coal;

port handling: material transfer of bulk cargo ships;

building materials production: lifting and conveying system for cement and sand and gravel;

grain processing: grain storage and out of warehouse operations.

Advantages

1.The maximum conveying angle can reach 30, which is 50%

2.higher than the ordinary conveyor belt. It effectively prevents the sliding

3.phenomenon of powder and granular materials during the conveying process.

4.The unique drainage groove design ensures continuous and efficient operation in a humid environment.

5.The service life is more than 1.5 times that of the ordinary conveyor belt

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.