Manufacturing Supplier Heavy-Duty Steel Cord Rubber Conveyor Belt for Mining Industries

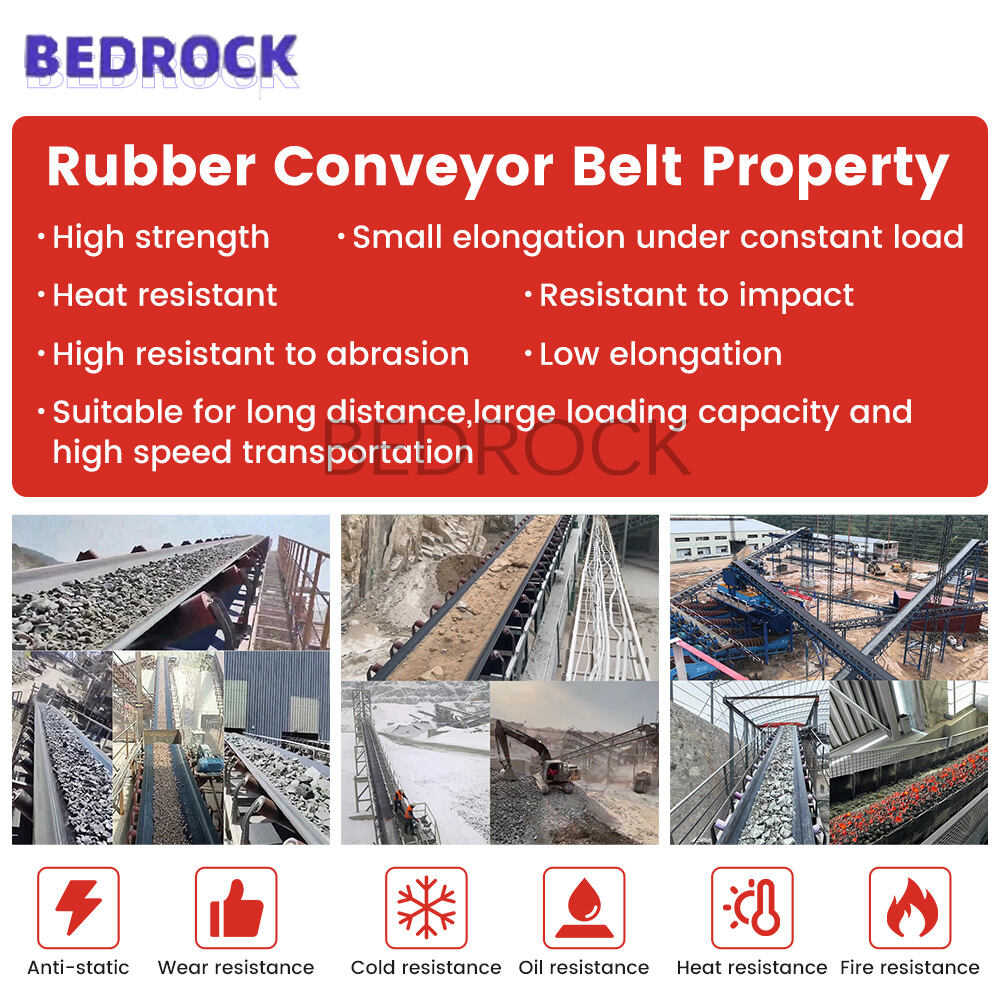

Steel cord conveyor belts are high-performance rubber transport belts that utilize steel cords as their primary reinforcement material, providing exceptional mechanical properties and durability. These specialized belts are characterized by their outstanding tensile strength, which enables them to withstand heavy loads and high tension during operation. Their excellent impact resistance makes them particularly suitable for handling abrasive materials and withstanding sudden shocks in demanding industrial environments. The steel cord construction grants these belts an extended service life compared to conventional fabric-reinforced belts, significantly reducing maintenance costs and downtime. Additionally, they exhibit superior flex resistance, maintaining structural integrity even under continuous bending and flexing movements. These combined advantages make steel cord conveyor belts the ideal choice for long-distance transportation applications, where reliability and performance are critical factors in bulk material handling systems.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

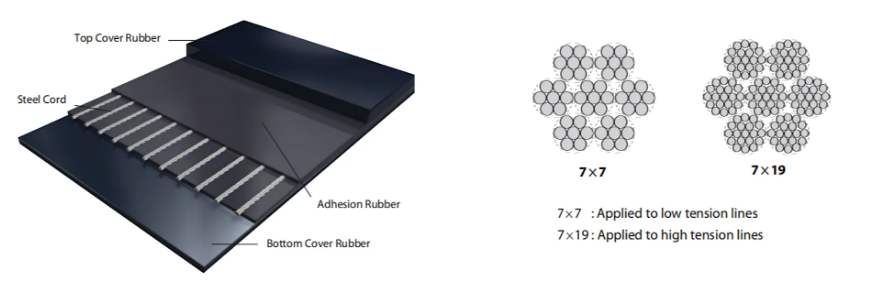

Steel cord conveyor belts represent an advanced class of rubber-based transportation systems that incorporate high-tensile steel cables as their primary reinforcement. These specialized belts feature a sophisticated multi-layer composite construction where high-grade steel cord reinforcements are precisely positioned and fully encapsulated within premium quality rubber matrix materials. The steel cords are typically arranged in parallel arrays, with each individual wire coated in a protective zinc layer to prevent corrosion and enhance bonding with the surrounding rubber. This engineered structure provides an optimal balance between flexibility and strength, delivering unparalleled tensile properties capable of supporting exceptionally heavy loads while enduring extreme operational tensions without deformation or failure.

The belts' robust design grants them remarkable impact absorption characteristics that effectively dissipate the energy from sudden material drops and dynamic loading stresses during continuous operation. Their advanced material composition, which includes specialized rubber compounds with optimized elasticity and wear resistance, ensures superior fatigue resistance when subjected to constant flexing around conveyor pulleys and idlers. This enables extended operational lifespans that significantly outpace conventional conveyor belt solutions, often lasting three to five times longer under comparable working conditions. The durability improvements translate directly into reduced maintenance requirements and lower long-term operational expenditures, as the belts require fewer replacements and repairs over their service life.

Additional performance benefits include exceptional dimensional stability, with minimal elongation under load and consistent thickness retention throughout their operational cycle. The belts maintain their structural integrity even when exposed to temperature variations, moisture, and chemical contaminants commonly found in industrial environments. Their low rolling resistance characteristics contribute to energy efficiency, reducing power consumption during operation.

Demonstrating consistently reliable mechanical performance even under demanding conditions, steel cord conveyor belts maintain dimensional stability and operational efficiency across a wide range of environmental challenges. Their exceptional performance characteristics make them the ideal choice for high-capacity, long-distance material conveyance in heavy industries including large-scale mining operations (handling ores, coal, and aggregates), bulk material handling at major ports (transporting grains, minerals, and containerized cargo), and continuous material transport in power generation facilities (moving coal, biomass, and ash). These belts continue to deliver dependable performance in complex working environments involving variable speeds (from slow-moving heavy loads to high-speed sorting systems), high throughput demands (up to several thousand tons per hour), and challenging material characteristics (abrasive, corrosive, or irregularly shaped), making them a cornerstone technology in modern industrial material handling systems. The adoption of steel cord belts in these sectors has proven to enhance productivity while maintaining strict safety standards and operational reliability.

Specifications

| Model | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 |

| Tensile Strength at Break (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 |

| Diameter (mm) | 3 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 |

| Spacing (mm) | 10±1.5 | 10±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 16±1.5 |

| Upper Adhesive Thickness (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 |

| Lower Adhesive Thickness (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 |

Applications

Steel cord conveyor belts are widely used in long-distance, high-capacity material handling applications across industries such as mining (including coal and metal mines), ports, power generation, and building materials.

Advantages

1. High strength with a high safety factor

2. Minimal elongation and short tensioning travel distance

3. Secure wire rope-rubber bonding with excellent dynamic performance

4. Flexible belt body with superior grooving capability and outstanding straight-line running

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.