Importance of Mining Conveyor V Belt in Mining Industry The mining industry relies on conveyor belts to transport materials taken from the the mine for processing. Picture a long belt that never stops moving, transporting heavy materials across great distances, under- or aboveground. These belts enable miners to work more quickly and safely, as they do not have to lug around heavy bags by hand. Bedrock produces robust, long-lasting conveyor belts that can withstand the harsh mining environment. Those belts need to be robust, have decent life span and continue running efficiently even in rough conditions. Behind every commercial zone is a mine, and beneath the surface of the mines themselves can be found the equipment which makes the production of dancing disco floors possible: a mining conveyor belt. It's not just simply a one size fits all category, unless that is you're working on opening up your own mine – then yeah. A mining conveyor belt isn't actually just a type of belt, it's an integral portion of several machines used in combination for things like heavy-duty rock crushing and moving into new areas to crush up large piles of rocks and transport unused treasure (which may vary depending on whether or not gold grows on trees.) Without something to help move them, nothing would get done -and everything must eventually be done each day.

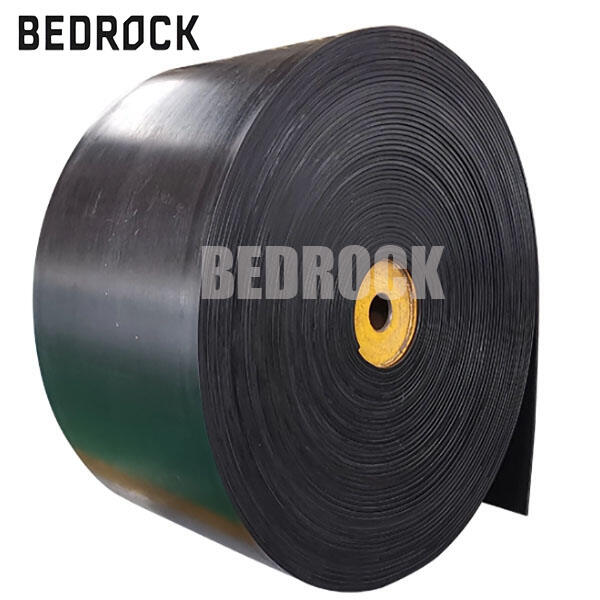

Features and Characteristics of High Quality Mining Conveyor Belts Good quality mining conveyor belts have several features which make them ideal for use in harsh mining conditions. They must be strong, first of all. Minerals can be heavy and jagged, so the belt must be tough enough not to tear or snap. Bedrock conveyor belts cover steel cords and fabrics with punishing amounts of rubber to ensure they don’t wear out easily. Resistance to water and heat are also important. Mining may occur in either wet or extreme heat conditions, so belts should withstand these elements and not experience damage from them. Certain belts from BEDROCK come with unique covers that ward off water and heat. It’s also really flexible. The belt needs to be able to bend around rollers and pulleys without breaking. If it is too stiff, the belt can also break easily. An excellent mining conveyor belt also has the ability to scale burning up, in addition to the ash and dust it produces. BEDROCK’s belts are smooth so they’re easy to clean and materials won’t stick. Safety is something else to consider. The belt should not slip even unintentionably and cause any risk. That’s why BEDROCK has added special textures and designs that help grip the materials and minimize slipping. Moreover, a solid mining conveyor belt should last you a long while without needing close attention all the time. BEDROCK quality tests each belt a minimum of three times for length, flex, and tension before sending it out the door. Therefore what you get is a solid piece which will keep your pants supported and pleated for many years to come. When belts are manufactured meticulously and with the proper materials, mining work is made safer and easier.

How to Find the Right Mining Conveyor Manufacturer in China Going for the perfect mining conveyor manufacturer in china is one of those essential decisions you need [.]

Not only is it not easily solved why a 10-inch kitchen knife would be necessary to defend oneself on the street outside of a Raiders game? Belts come in all sorts and some are better for certain tasks. Now first of all, you have to consider what sort of materials are going for in the tent. If the stuff is exceedingly sharp, like broken rocks, a logging belt has to be harder still. BEDROCK has a belt that can withstand sharp rocks without getting holes or cuts. If the material is damp, or sticky, a belt with a special cover that doesn’t stick to itself would be preferable. Now think about the heaviness of the fabric. Heavyweights demand belts with beefy layers in them. If the belt is too thin, it wears through too quickly. The engineers at BEDROCK help customers choose the right thickness and strength for their purpose. And the velocity with which the belt is moving is important, too. At times, when the shorthand conveyor belts are traveling at fast speeds, and need special designs to keep material on its surface without dropping off. Width and length of the belt gets determined by the mining site as well. If it’s too narrow, the belt won’t hold much material; too wide and it can be expensive with cumbersome installation. The temperature and weather where the belt will be running is another consideration. Some of the belts by BEDROCK hold up well in extreme cold or hot temperatures, remaining flexible and strong. Serviced should also be considered. Belts that require fewer adjustments save time and money. BEDROCK builds its mining conveyor belts to be easy to maintain, so if something does go wrong it can be fixed quickly. In the end, safety is a priority. The belt must not have inferior slippage making the dust cloud to put worker's health at risk. BEDROCK’s offerings have certain features that make work safe. The best mining conveyor belt is depending on the application of a particular mineral. All the material which moves on conveyor, it should have a specific hardness and density, this way you will be able to protect your conveyer in better way. It’s definitely price, but it’s also wanting to know that you’re getting a belt that will last and do the job.” At BEDROCK we’re proud of the fact that we take care of those who dig for a living – to help people find and use the belts that are best-suited for their job makes mining safer and more effective every day.

Mining Conveyor Belts: These belts are anchored by steel cables, which run the length of the belt. As such, different jobs in the mines require a different kind of conveyor belt as the conditions and materials can vary greatly. At BEDROCK, we understand that the right belt can make your mining operation run more safely and effectively. The size and weight of the material to be conveyed, for example, may require a strong, thick belt if it is moving rocks or large pieces of ore at a mining site. These belts are constructed from sturdy materials so they do not snap easily. Alternatively, for mining operations where materials are relatively small or light such as sand or coal dust, a lighter belt can be satisfactory. These belts are speedier and more energy efficient. Certain mining jobs also require belts that will maintain their grip in conditions of heat or wetness, such as occurs within deep mines or underground. BEDROCK provides belts with special covers which prevent water, heat and chemicals. This makes the belts more durable even in tough mining situations. Then there’s the modular belt conveyor that is easy to fix in case of damage. This sort of belt is useful for locations where the belt must bend a lot or where it must be cleaned regularly. Selecting the right mining conveyor belt depends on a number of factors like the size, the weight, and the speed of the materials that will be transported, as well as the distance they will need to cover. BEDROCK can also guide mining customers in choosing the right belt for their needs, to ensure a smooth and safe operation. Choose the wrong belt and you could be in for a slow down, damage or a crash so it’s vital to make the right choice. By knowing the various kinds of covered conveyor belts and which types are more suitable for what, miners can add to their work and make sure that everything within them operates smoothly for years on end.

Mining applications pose a variety of unique challenges for conveyor belts. They are usually hot, or dusty, or wet — and riddled with sharp rocks. Prolonged exposure to harsh conditions will cause even the most durable conveyor belts to wear out or break. To ensure mining conveyor belts continue to work as they did when brand new, you need to follow a few simple rules. At BEDROCK we take great pride in the safety and longevity of belts for mining. One, use the right belt material. For instance, belts constructed of tough rubber and with added layers on the inside are resistant to cuts and tears from sharp rocks. BELT STRUCTURES BEDROCK belts are specifically built to address these issues. Then, regular cleaning is key since dust and dirt can accumulate, causing the belt to either slip or wear unevenly. Clean the belt with brushes or an air blower to help it run smoothly. Another key step is to regularly inspect the belt for minor issues, like cracks and loose parts. It’s when they’re not addressed that minor issues can fester. BEDROCK advises routine inspection and maintenance schedules to catch problems early. It is very important as well to check if the belt is working perfectly on the rollers as well as pulling. When the belt is not straight, or rollers are seized up, it can lead to abnormal wear and even accidents. Sensors and monitoring devices can help maintain the belt’s alignment and functioning. BEDROCK has some smart solutions that make it possible for mining operations to monitor the health of their conveyor belts in real time. Lastly, it is essential to train the employees who operate and maintain conveyor belts. They need to know what types of problems to look for and how to use belts safely. BEDROCK also supports training programs that cover the proper approaches to conveyor belt handling in mining. By doing so, mining conveyor belts can become comfortable and safe around the precious metal for thousands of years to come in even the harshest of environments. That saves money and protects miners.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.