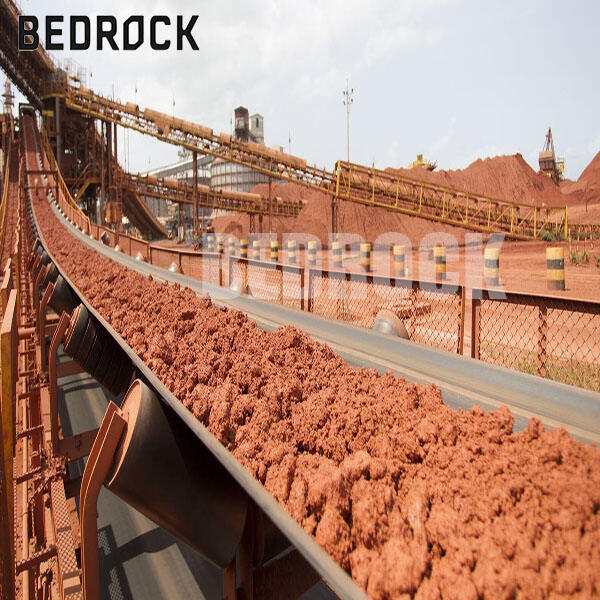

Mining Conveyor belts are of such great importance that they are used to transport rocks, coal and other form of minerals from one spot to another in mining sites. These belts transport heavy product more quickly and safely allowing the work to become easier and faster. There would only be hard and slow mining work without decent conveyor belts! Companies like BEDROCK ensure these conveyor belts are tough and reliable enough for the harsh conditions involved in mining. But when you’re selecting a conveyor belt supplier, price isn’t the only thing you have to consider. This article is going to discuss why conveyor belt suppliers are so critical and where you can get the very best ones for larger mining projects.

Mining Conveyor Belt Suppliers These mills are extremely credible and create a large amount of value for... Continue Reading → Imagine transporting rocks and dirt by hand, or even by small machines — it would take forever, and cost a truckload of money. Conveyor belts make it easy to move these materials which can help deliver products from one point to another continuously and save time and money. You have to know the mining environment if you supply this sort of belt because it’s nasty and tough. The belts must withstand tears, heat, cold, and occasionally chemicals. BEDROCK knows these challenges well. We develop belts that are durable and designed to work better in harsh conditions. It’s not just a matter of creating belt; it’s also about making sure that such a belt doesn’t break during the course of any busy day. When a conveyor belt breaks, production ceases, and that can be very expensive. Reputable suppliers can prevent this by providing a rough belt and speedy assistance if trouble arises. And good suppliers offer advice on the correct belt for various materials and machines. For instance, certain belts are best for sharp rocks and others do better on coal or sand. This sort of knowledge really matters. Masterbelts listens to what the mining company needs, then matches the belt to them. Sometimes the belts are even designed with special features such as extra layers or stronger edges to prevent wear. “Once a supplier has access to these kind of details, they’ll be able to save your mine wasted expenditure when it comes to belts wearing out quickly or being the wrong fit for the job. Mining conveyor belt suppliers are not just vendors, but also an essential part of many businesses and organisations.

It Can Be Hard To Find A Good Supplier For Mining Conveyor Belts It can be really hard to find a good supplier when you have a big project and you need lots of conveyor belts that work well. And in the case of big mining projects, there's often a need for belts that can carry heavy loads around the clock. Because we specialize in belts that work for these tough needs, you can consider BEDROCK one place to check. But how can you tell if a supplier is reputable? One is to see if the supplier has a history of doing large mining jobs. A firm that has worked with large mines in the past will understand what is required and what can easily go wrong. Another way is to consider the belts themselves. Are the belts of durable materials? Do they come with guarantees? Also - dead important to have support services. When something doesn’t work, you want fast help to make it right. The flexibility to provide this kind of rapid support is something that BEDROCK offers because we understand the cost of downtime. They sometimes have custom designs to fit special machines, or odd materials. This can be a real asset, as no two mining locations are the same. You may look for such suppliers online, speak with other mining companies or attend industrial trade shows to find them. It’s also helpful to speak to others who have worn the belts. At BEDROCK, we believe in no nonsense talk so the clients can be assured, they have made the right choice. It’s worth to ask about how the belts are constructed and what sort of testing they undergo prior to being delivered. This helps avoid surprises later. But for big projects, it is wise to plan ahead and order belts with a bit of leeway. This allows the supplier to prepare and ensure everything comes when it’s needed. Going with a provider like BEDROCK is about more than just product; it is having your supplier also be a true partner that understands the massive scale and pressure involved in big mining.

If you are planning to purchase a set of mining conveyor belts, there are certain issues that you will need to be aware of. Conveyor belts are critical in mining, which is why they move tons of rocks and minerals from one place to another. A poor belt can break or fail, leading to delays and a hefty bill. A common problem is purchasing belts that are not strong enough for the kind of mining you do. Some vendors may provide belts that might seem cheap but are not so strong for carrying heavy loads, or handling the rough shipboard environment. This led extremely quickly to the destruction of the belt, if not of a terrible accident and shutdown in operations. Another issue is the failure to inspect the quality of belt material. Mining operations require they must be made of a rugged material that can withstand the rough use of mining, sand, gravel and crushed stone conveyor belts. If the belt is not tough enough for the brutal mining environment, it won’t last long. And do also try to avoid companies which offer unclear product info. Some suppliers even fail to describe critical features such as belt thickness, strength or safety capabilities. Without this information, you have no way of knowing whether the belt will be appropriate for what purpose you intend to use it. Lastly, bad customer service from vendors can create lots of headaches. Your time and your money are lost if the supplier doesn’t assist you in installing or correcting problems. But at BEDROCK, we keep the belts running where they should. And we provide straightforward information and assistance so you can select the correct belt for your production needs and keep your mining project running on time and on budget.

Purchasing a mining plant means you have to be very careful where you buy them because the advancement in technology and keeping up with safety standards is essential. Mining conveyor belts must be strong enough to stand up to a large load of heavy materials, which are also known as Muck you can get more information on muck conveyors here. While trying to find a supplier, you should select one that uses modern technology in the construction of belts. For instance, contemporary conveyor belts come with specific layers that ensure protection from cuts and heat respectively. Some belts also include sensors to know when the belt is frayed or something is amiss. This also help in avoiding accidents and to keep the mining area safe. These standards are stringent because safety is a very big deal in the mining business. These rules help ensure that the conveyor belts do not start fires, lead to slips or pose other hazards. A good supplier will test their belts numerous times before it is shipped out to ensure they are safe to use. At BEDROCK, we are concentrating on technology freshly.Constructed conveyor belts that support belts can be achieved with safety. Our belts are safety accredited, to AFNOR CDG 5580-7101 at industrial level and tested effective in harsh mining conditions. When you purchase from us, that’s just what you are purchasing—belts that work for your workers and equipment, ensuring that mining work can be done as fast and safe as possible. Be sure to ask your supplier about the safety features and technology incorporated into their belts. This will ensure that you are purchasing the base belt for your mining needs.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.