Concrete pumping station, also known as concrete will be transported to the high place with the help of pump. These conveyors are convenient to load, unload and move, and will not damage wet or dry floors during movement of concrete. Rather than carrying concrete to the location or pouring it from a bucket, a conveyor system brings along the ready mix and pours it where needed. Words such as strong and reliable are already used to describe BEDROCK’s well-built concrete conveyor systems, which most importantly also perform well under the harshest conditions. Whether you’re in the business of making roads, buildings or bridges, these conveyor belt systems are an integral aspect that is sure to keep your projects on track without any sort of major issue.

Choosing the perfect concrete conveyor system for wholesale means considering a lot of different things all at once. Firstly, the conveyor size is of great significance. Too small a conveyor belts and it can’t carry enough concrete, which delays the job. Too large, and it could be difficult to maneuver or fit in place. BEDROCK has different sizes allows you to find one that is right for you. Then, the type of material used in constructing the conveyor makes a huge difference. Concrete is heavy and tends to be abrasive, so the conveyor has to be constructed with tough metal that won’t break or abrade. Also think about how this system is powered.

Concrete conveyor systems give trouble sometimes– this is only natural since they are in continuous operation every day. One frequent problem is the belt slipping or not going. This is the case when ther isn't enough tension on the belt or parts are damaged. If the belt skips, inspect for proper tension first. Tighten it slightly and see if the test works. Other times the motor is running, but not very well — listen also for weird noises or no sound. If that motor is shot, it may just need fixing or a new one replacement. Another issue is the concrete adhering to the components of the mining belt conveyor. Dry concrete can coat the system, or the belt becomes weighted. To remedy this, clean out the conveyor after each use. Smooth BEDROCK conveyors do not stick as much, but cleaning is still essential.

The concrete conveyor operates efficiently to deliver the concrete where it needs to go. These systems make it possible to move concrete fast and safely from one place to another. At BEDROCK we are well aware these conveyors make your job easier and quicker. You can see concrete conveyor when you visit big buildings, bridges, roads and tunnels. In areas workers can’t drive to, or in other hard-to-reach places, conveyor systems transport wet concrete between and over obstacles without spilling an ounce of it, letting it into the hands of their work-ready colleagues more quickly. For instance, when building high-rises, concrete needs to reach dozens of stories into the air. Dragging it by hand or on trucks is slow and hazardous.

If you want them to last for a long time, taking good care of the concrete conveyor systems is crucial. We at BEDROCK support our buyers that rely on conveyor systems for large-scale projects by continually being available for any questions they would have regarding taking care of their equipment. The best maintenance comes down to cleaning the conveyor machine every time you use it. Concrete is gummy and dries quickly. If you don’t clean it, the concrete will accumulate and cause issues. Workers should scrub away all remaining concrete with water and brushes. Next, it is crucial to make sure that the moving parts work. Conveyor belts, rollers and motors should be inspected regularly. Any worn-out or broken parts should be repaired or replaced immediately. This prevents the system from crashing ‘in the middle of a project’.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

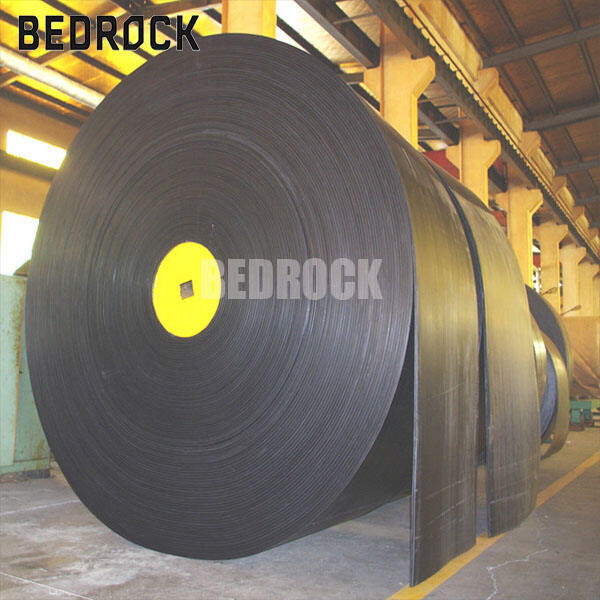

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.