Customized Size NN Nylon Conveyor Belt Abrasion Resistant Chevron Patterned for mining

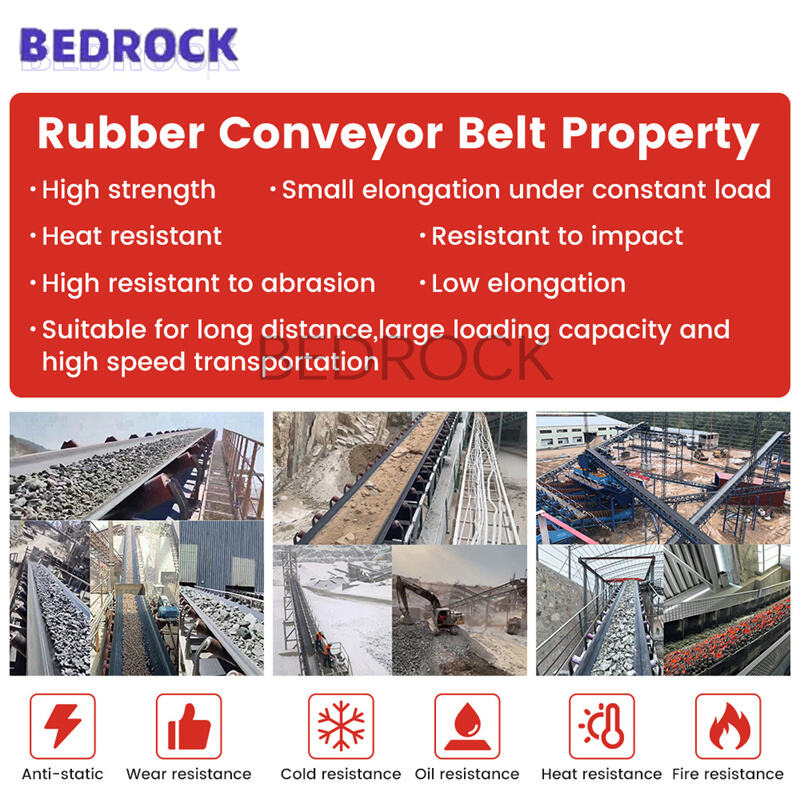

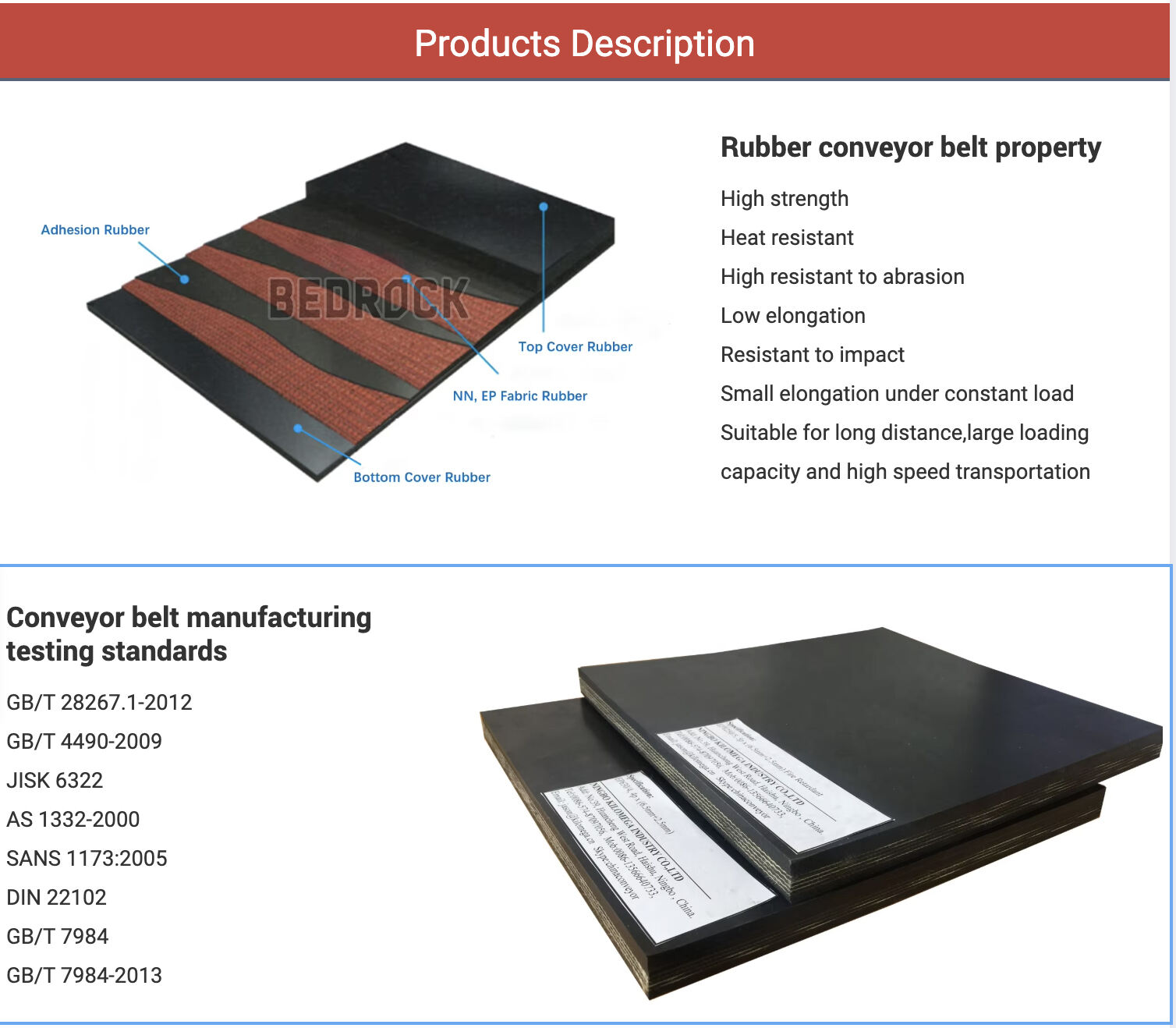

Nylon conveyor belts feature a high-strength nylon canvas skeleton, offering excellent abrasion resistance, tensile strength, and flexing performance for smooth operation with minimal deviation. The product resists oil and alkali, boasts high tear resistance, and is suitable for conveying various bulk materials and packaged goods. Operating temperature range: -25°C to 80°C.

Nylon (NN)conveyor belt has the characteristics of thin belt body,high strength,impact resistance,goodgroove formation,strong inter-layer adhesion,excellent fexibility and long service life.It is suitable for short and medium distances and high load capacity.,transporting materials under high-speed conditions.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

In addition, nylon conveyor belts are engineered to deliver consistent performance in diverse industrial environments. Their robust construction ensures a long service life, even under demanding conditions such as heavy loads or high-speed operations. The material's inherent resistance to abrasion makes it ideal for applications involving sharp or rough materials, while its flexibility allows for easy adaptation to different pulley systems and conveyor configurations. Furthermore, the belts' oil and alkali resistance properties make them particularly suitable for food processing, chemical manufacturing, and other industries where exposure to corrosive substances is common. Maintenance is minimal due to the durability of the nylon canvas, reducing downtime and operational costs significantly. These belts also exhibit excellent adhesion between layers, preventing delamination and ensuring reliable performance over time. With their ability to handle both wet and dry materials efficiently, nylon conveyor belts provide versatile solutions for material handling needs across multiple sectors. Whether used in mining, agriculture, logistics, or manufacturing, they ensure optimal productivity and safety, meeting the rigorous demands of modern industrial operations.

Specifications

| Fabric specs | Ply thickness (mm/p) | Strength series | Cover thickness | Widt h(m m) | ||||||

| 2ply | 3ply | 4ply | 5ply | 6ply | Top | Bottom | ||||

| NN-100 | 0.75 | 200 | 300 | 400 | 500 | 600 | 1.5–8 | 0–4.5 | 400–2500 | |

| NN-150 | 0.80 | 300 | 450 | 600 | 750 | 900 | 500–2500 | |||

| NN-200 | 0.90 | 400 | 600 | 800 | 1000 | 1200 | ||||

| NN-250 | 1.15 | 500 | 750 | 1000 | 1250 | 1500 | ||||

| NN-300 | 1.25 | -- | 900 | 1200 | 1500 | 1800 | 100–2500 | |||

| NN-400 | 1.45 | -- | -- | 1600 | 2000 | 2400 | ||||

| NN-500 | 1.55 | -- | -- | 2000 | 2500 | 3000 | ||||

| Core material | Adhesion strength | ||

| Between fabric layers (N/mm) | Between rubber and carcass (N/mm) | ||

| Thickness of Layer ≤1.5mm | Thickness of Cover ≥1.5mm | ||

| Nylon canvas | ≥5 | ≥4.5 | ≥5 |

| Extended performance | |||

| Full thickness longitudinal tensile elongation at break | ≥10% | Full thickness longitudinal reference force elongation ≤4% | |

| Cover Grade | Tensile Strength≥ | Elongation at break≥ | Wear loss≤ | Tensile Strength and Elongation at Break after Aging |

| Mpa | % | mm3 | % | |

| H | 24 | 450 | 120 | -25~+25 |

| D | 18 | 400 | 100 | -25~+25 |

| L | 15 | 350 | 200 | -25~+25 |

Applications

Widelyused in mining,coal fields,chemical industry,metallurgy,construction,ports and other departments.

Advantages

1.The belt body has good elasticity,impact resistance and wear resistance.

2.Good flexibility and easy to groove.

3.No mildew corrosion occurs.

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.