Customized Chevron Conveyor Belt Highly Durable Conveyor Belt for High-temperature Materials

A high-temperature conveyor belt is a specially engineered industrial conveyor system specifically designed to maintain optimal performance and durability when operating in extreme high-temperature environments. These specialized belts are constructed using heat-resistant materials and advanced manufacturing techniques to withstand prolonged exposure to elevated temperatures that would degrade or damage conventional conveyor belts. Unlike standard conveyor belts that might warp, melt, or become brittle under thermal stress, high-temperature conveyor belts feature reinforced structures and specialized coatings that preserve their structural integrity, flexibility, and functionality even when continuously exposed to intense heat conditions commonly found in industries like metal processing, glass manufacturing, or foundry operations.

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

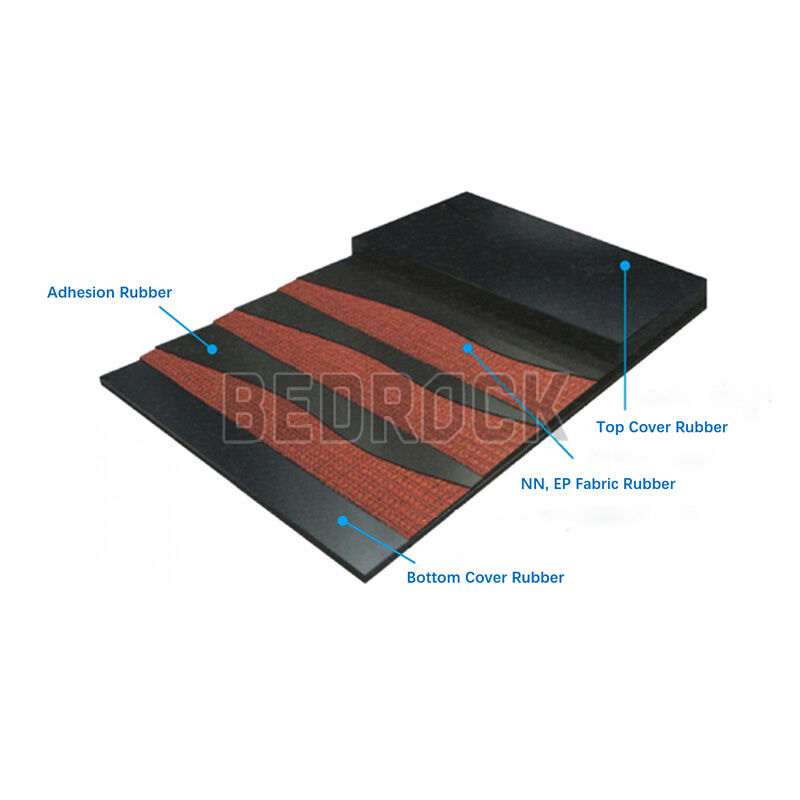

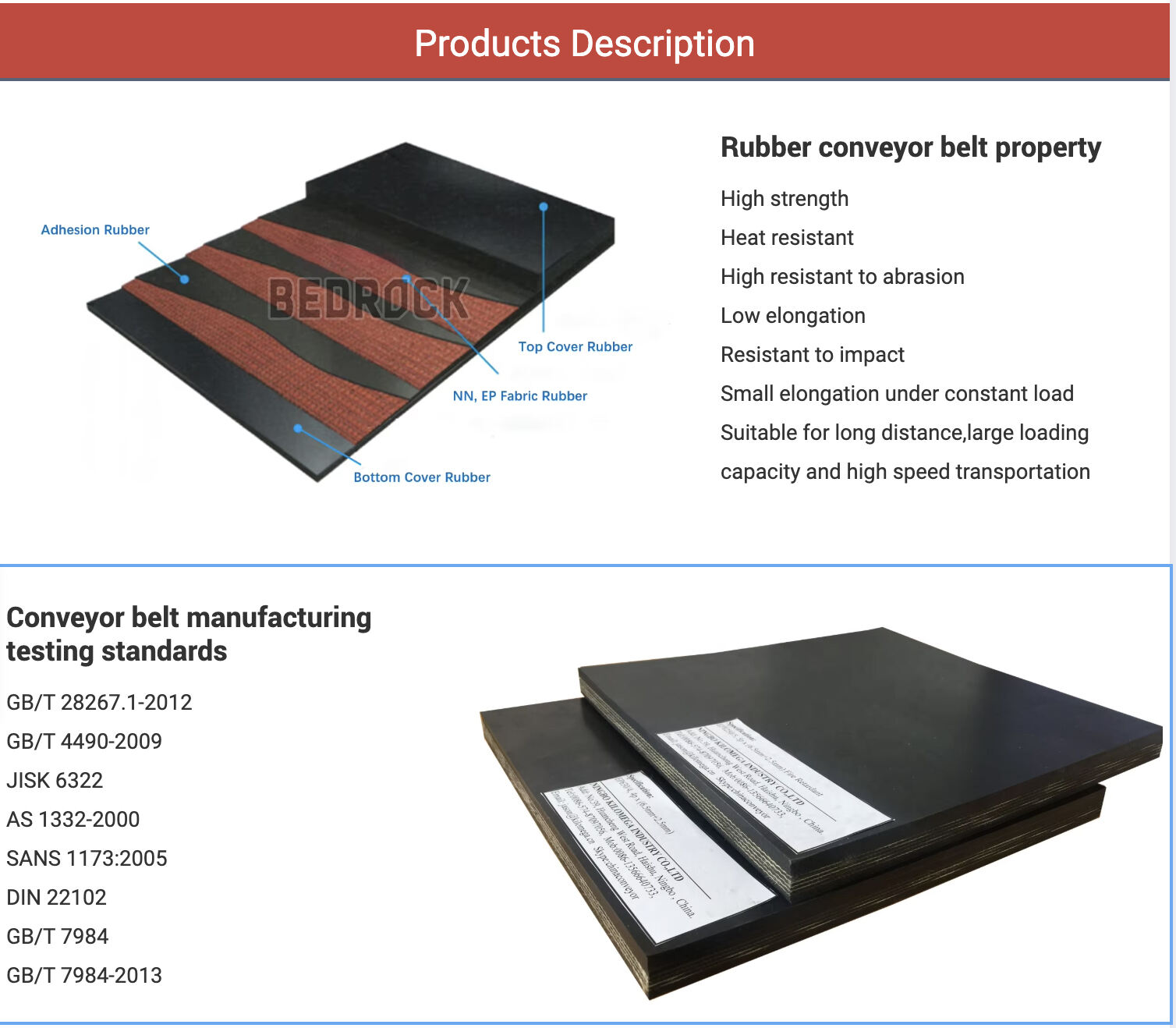

The sophisticated product core is meticulously crafted using a premium-grade, high-modulus, low-shrinkage polyester canvas fabric, which has been specifically engineered to exhibit exceptional tensile strength properties. This robust fabric forms the foundational layer, ensuring the product can withstand significant mechanical stress without compromising its structural integrity. The outer cover compound is expertly formulated with either EPDM (ethylene propylene diene monomer) or chlorinated butyl rubber, both renowned for their superior resistance to high temperatures. These advanced rubber compounds are meticulously processed through a series of precision lamination, controlled vulcanization, and other specialized manufacturing steps, all utilizing high-temperature resistant materials to ensure optimal performance.

To further enhance the product's durability and reliability, the core undergoes a proprietary impregnation and setting treatment process. This specialized treatment significantly increases the bonding strength between the layers, creating a cohesive and resilient structure. When subjected to normal operating conditions with temperatures below 180°C (356°F), the product demonstrates remarkable dimensional stability, exhibiting minimal elongation deformation. Additionally, it boasts exceptional abrasion resistance, ensuring longevity even in harsh operational environments.

Primarily designed for high-demand industrial applications, this versatile product is extensively used in the metallurgical and construction industries. It is specifically engineered to handle the challenging task of conveying high-temperature materials such as sintered ore, metallurgical coke, and cement clinker. These materials are often abrasive and can generate substantial heat during transport, making the product's superior high-temperature resistance and wear resistance characteristics indispensable. The meticulous selection of materials and the precision manufacturing processes employed ensure that the product not only meets but exceeds the stringent requirements of these demanding industries, providing reliable and consistent performance even under continuous high-temperature exposure conditions. This combination of advanced materials and expert craftsmanship results in a durable and dependable product that stands up to the rigors of extreme operating environments while maintaining its structural integrity and functionality over extended periods.

Specifications

| Cover Rubber grade | 8MPA,10MPA,12MPA,15MPA 18MPA,20MPA,24MPA,26MPA | |

| Top+Bottom thickness | 3+1.5,4+2,4+1.5,4+3 | 3/16"+1/16",1/4"+1/16" |

| Belt thickness | 3mm,4mm,5mm,6mm,7mm,8mm,9mm,10mm,12mm,15mm,20mm,25mm | |

| Belt length | 10m,20m,50m,100m,200m,250m,300m,500m | |

| Belt edge type | moulded(sealed) edge or cut edge | |

| Belt width (mm) | 500,600,650,700,800,1000,12001400,1500,1800,2000,2200,2500 | 18",20",24",30",36",40",42"48",60",72",78",86",94" |

| Tensile strength | EP315/3,EP400/3,EP500/3,EP600/3 EP400/4,EP500/4,EP600/4EP500/5,EP1000/5,EP1250/5 EP600/6,EP1200/6 | |

Applications

Steel cord conveyor belts are widely used in long-distance, high-capacity material handling applications across industries such as mining (including coal and metal mines), ports, power generation, and building materials.

Advantages

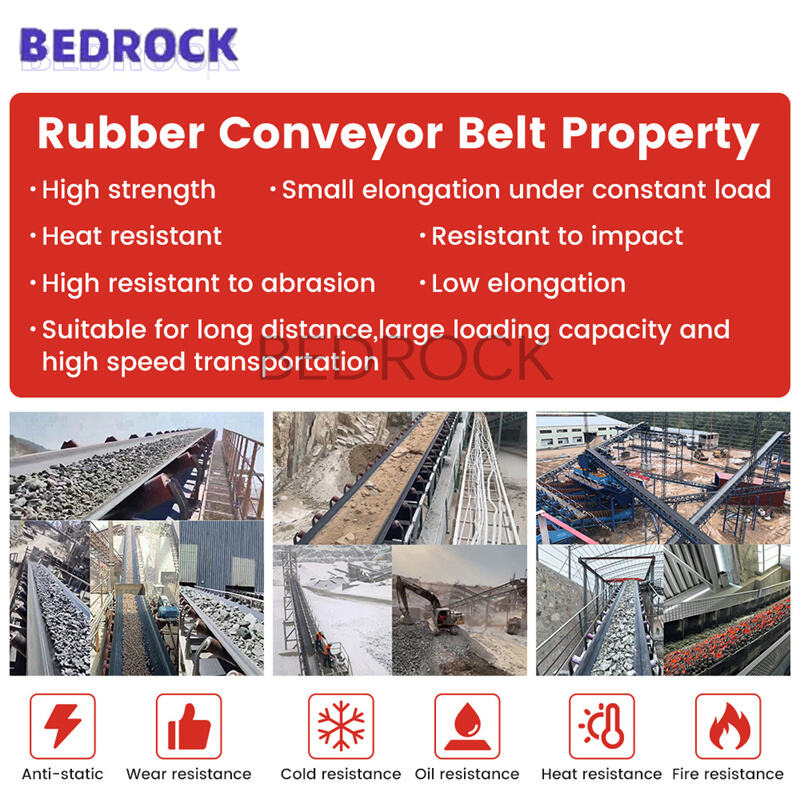

1. High-temperature resistance

2. Carry heavier materials without deformation or breakage

3. Suitable for harsh environments, with excellent chemical stability

4. Long service life, reduced maintenance costs

FAQ

1. What are the advantages of your conveyor belts compared to other brands?

1:Targeted Design: Based on years of field experience in Saudi Arabia, we engineer our belt’s ply count and rubber grade to precisely match your application.

2:Localized Service: We provide "hands-on" technical support throughout the entire process—from selection and installation to subsequent optimization—ensuring you achieve optimal results, not just receive a belt.

3:Cost Advantage: We have our own factory, eliminating middlemen. This allows us to offer more competitive prices while guaranteeing quality. We deliver long-term, stable operation, not just a product.

2. Is your conveyor belt under warranty? How long is the warranty period?

We provide clear and fair warranty terms to ensure mutual understanding:

1:A one-year warranty is provided under normal operating conditions (covering issues like delamination and core breakage).

2:Normal wear and tear of the top and bottom cover rubber is excluded.

3:Punctures and cuts caused by external factors are not covered.

Our Hot Vulcanized Jointing Service is covered by a separate one-year warranty. (This warranty excludes issues resulting from mechanical damage, human error, or improper maintenance.)

3. How is the belt splicing handled? Do you provide on-site service?

The splice is the "lifeline" of any conveyor belt, and we treat it with utmost importance. We offer:

1:Professional Hot Vulcanized Splicing Service: Our engineer team uses professional equipment to ensure a splice efficiency of over 90%, achieving a strength nearly equal to the belt itself.

2:On-site Guidance & Execution: We don't just advise; we can dispatch our engineers to your site to ensure the splice is done correctly the first time, preventing the risk of future breakages during operation.

4. What is the service life of the belt?

The service life of a conveyor belt depends on various factors, including material abrasiveness, load capacity, operating environment, and maintenance standards.

Based on our experience serving similar clients in Saudi Arabia, under normal conditions and with proper maintenance, our products are typically designed to last 1-2 years.

Most importantly, through accurate selection and regular maintenance tracking services, we proactively help you avoid abnormal wear, striving to maximize the product's service life and thereby reduce your cost per ton conveyed.

5. What is your response if we encounter a problem with the belt?

We have established a localized rapid response mechanism in Saudi Arabia:

1:Technical Consultation: For any operational queries, we provide remote technical support within 24 hours.

2:Emergency Breakdowns: For critical issues causing downtime, we commit to providing a clear on-site support arrival time and establishing an emergency communication channel.

3:Spare Parts Support: We maintain a local spare parts stock in Saudi Arabia to ensure the rapid supply of critical components.

Our goal is to become your long-term partner, not just a one-time supplier. Therefore, resolving issues quickly is in our mutual interest.