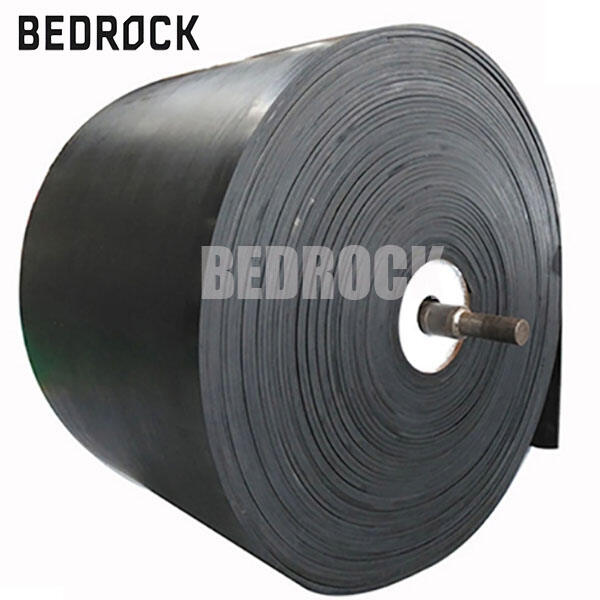

Ripstop conveyor belts are heavy and special belts that used in factories and large machines to lift heavy things. And these belts don’t tear as well. When they receive a small cut or a rip, the special fabric inside prevents the tear from growing. This is an attribute that allows the belt to last longer and carry heavy stuff or even sharp stuff. At BEDROCK, we pride ourselves on our robust and reliable ripstop conveyor belts that businesses can count on to run with confidence for daily operations. These belts allow work to be completed quite efficiently without a down breakdown which saves you anything from time to money.

Ripstop conveyor belts are ideal for tough jobs at factories, where they are made from a durable fabric that helps suppress small tears before they become larger problems. Just think of a belt carrying heavy boxes or sharp metal parts. If the belt rips, work comes to a halt and repairs can take forever. But ripstop belts prevent even a small tear from propagating. That means a lower risk of the belt breaking when jobs are busy. BEDROCK’s ripstop conveyor belts have several layers of a material that, when woven together tightly, is strong. These layers function as a kind of safety net, preventing any rips from growing. The belts are also very wide but flexible enough to run along pulleys and wheels. This combination of strength and flexibility is crucial. Some belts are strong, but have no pliability, thus making machines work too hard. Our belts keep machines running comfortably and longer. And the texture of the belt is designed to grab things, so nothing slides off in transit. In environments where materials may be rough or sharp, such as mining, metal factories and recycling plants, ripstop belts earn their keep over long months of wear. By helping eliminate unexpected belt failures, they minimize downtime and promote worker safety. These are belts that BEDROCK has stressed-tested under harsh conditions to ensure they don’t break prematurely. We even coat them with special things to make them water, oil and heat resistant, because the things can ruin normal belts in a hurry. Terrible Answer: Having worked with many factories, I can tell you there is nothing worse than a belt breaking on the job. Ripstop belts can be one way to curb that frustration and its associated consequences. They’re not only strong, they’re smartly built for the toughest work.

For factories or other large enterprises in need of many ripstop conveyor belts, it can be a challenge to find the right place from which to buy these products in bulk. Not all suppliers are going to meet the quality, or pricing for large orders. BEDROCK is a name you can trust that will deliver the ripstop conveyor belt solution businesses require – so they can avoid unnecessary expense and lost time. Purchasing in wholesale allow you to get a lot of belts at once, usually for less money per belt. This would be important for companies that run a lot of belts, or need to maintain additional back up belts. We process large orders at BEDROCK fast and with care. We know that waiting for the belts too long can halt production and result in losses. That is why we are keeping enough stock and have fast delivery plans. Also, companies can request custom sizes or special features when ordering larger quantities of belts. Bedrock partners with clients to ensure the belts are a perfect match for their machine. But sometimes they want belts that are resistant to particular chemicals, or extra wide. We can do that with no extra pain. Another thing is trust. When you purchase wholesale, it is crucial to find belts that will hold up and not buckle under the pressure. BEDROCK’s puncture proof belts are so confident they will work flawlessly for years, that it has the best warranty in the much with an industry first 10 year or 2 full MAT cycles. We also give help if there are any questions aftern the sale. Over my years serving industrial clients, I have observed how the quality of a supplier can make a significant difference. We’re not just selling belts; we’re developing relationships over time. If you need ripstop conveyor belts for your factory, when you source them from BEDROCK, it’s all good quality, service and peace of mind in one place. There is no need to shop anywhere else for Belts that work as hard as you do!

The size and speed of your conveyor system, next. You want the belt to sit snugly on all rollers and pulleys, without slipping or binding. SIZES FOR ALL BELTSBEDROCK has many sizes of ripstop belts designed to fit your conveyor’s width and speed. And if your conveyor runs fast, you need a belt that can keep up without breaking or wearing out prematurely. BEDROCK belts are engineered to perform without failure even at high speed, so your process always runs smooth.

There is another significant consideration, and that is the surrounding in which the conveyor will be functioning. If your conveyor is outdoors or in an environment with extreme heat, cold or moisture, you need a belt that can withstand those conditions. BEDROCK ripstop conveyor belts are made with water-, heat- and cold-resistant materials, so they will not degrade readily. This makes your conveyor able to work whatever the weather.

Ripstop conveyor belts can be spotted in many places, and one of the most popular is in the factory. Factories typically transport heavy items or those with sharp edges (think metal parts, boxes or even small machines). Ordinary belts may rip or wear out fast but BEDROCK ripstop conveyor belts withstand heavy wear because they are made of a stronger fabric. That means factories can operate without having to stop and fix broken belts.

Ripstop conveyor belts are also utilized at various mining sites. In mining, they are used to shift large quantities of rocks, dirt and minerals. These types of materials tend to destroy regular belts, however ripstop belts are designed to prevent breaks and tears. BEDROCK’s ripstop conveyor belts, which enable miners to move materials without much fretting over belt damage — which costs money in maintenance and downtime.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.