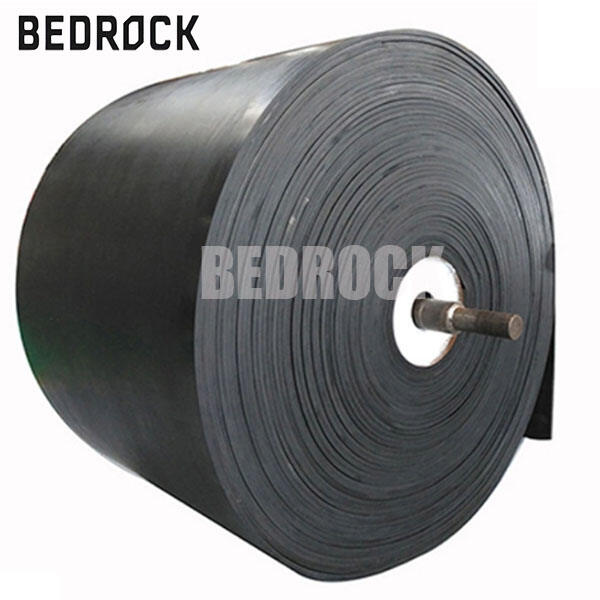

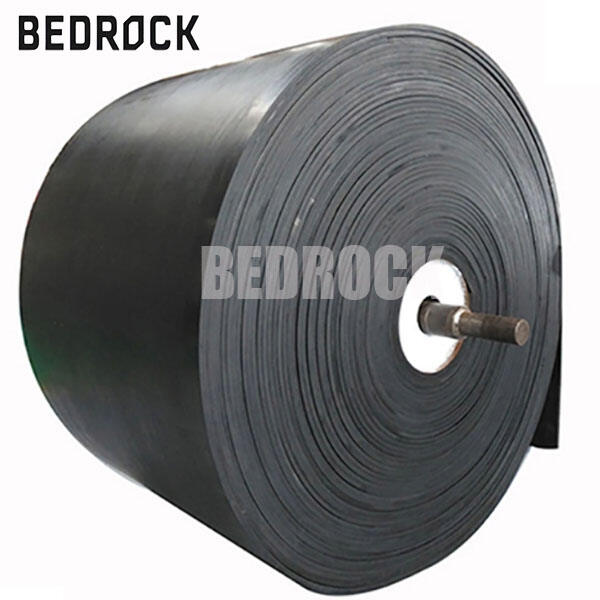

Oil resistant belts are used in a multitude of sectors. These belts help machines function smoothly despite oily conditions. Machines, when running, sometimes leak or splash oil. - This oil can cause the belt to slip, crack or break prematurely if not properly matched, by a manufacturer that focuses on belts just as this one does. That’s why it’s so important to select a belt that can withstand oil. At BEDROCK we are focused on belts that stay in play longer while the machines stay in play longer. Our belts are produced to withstand oil damage, so they don’t wear out quick. This will save you time and money because you don’t have to switch belts all of the time. Also, it ensures worker safety because a broken belt can cause machines to abruptly halt, possibly resulting in injuries. When you need a belt for oil and grit, and difficult environments, BEDROCK belts are the right call. For heavy-duty applications, consider our EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling.

Oil resistant belts are very important where the machines are in habit of using or getting in contact with oil frequently. Picture a factory in which machines churn all day and the oil gets everywhere. If the belt is not oil resistant on these, it may get slick or soft. This will cause the belt to slip, and in some cases, stop working or do so incorrectly. If a belt slips in, say, an auto factory, parts might not move at the correct speed and the entire assembly line slows or stops. Oil resistant belts retain their ability to transmit power despite being soaked in oil. That’s enough for machines to run and stop gently rather than all of a sudden. For that matter, some belts provide cracks or swelling when they come in contact with oil but a design Belt resistant to oil remains strong and pliable. That also helps protect the machine, since a bad belt can damage other parts. In industries such as mining, manufacturing or food processing, machines frequently come in contact with oil on their belts. Investing in oil resistant belts will likely save a company a great deal of money in repairs and replacements. The use of BEDROCK oil resistant belts can alleviate this problem. Our belts are manufactured using special oils which prevent the breakdown in oil. They've been tested in a lot of real factory environments to ensure they’re working well. Even under extreme pressure, or out in the heat of the field, BEDROCK belts won’t fold. That is why they are relied on in tough places. Workers are also safer since the belts don’t snap violently. This brings about fewer accidents and less machine downtime. So, oil resistant belts are more than just parts; they’re what keep machines safe and running well on a daily basis.

Choosing the proper oil resistant belt can be difficult. Before you buy, there are many things to keep in mind. First, consider what type of machine you have and how it works with the belt. Some machines move rapidly; others haul heavy loads slowly. These are the needs that a belt needs to meet. At BEDROCK, we say the belt material matters a lot. Some belts use rubber that turns soft with oil. Others are made of special rubber or synthetic materials that hold their strength in place. You’re looking for the strong stuff, good for heavy work. Next, consider the temperature at which the machine operates. When it’s very hot, some belts melt or change shape. BEDROCK belts do double duty in the face of heat and oil, yet never give out. The size of the belt as well as its shape should also be evaluated. This has to be a fit for the machine’s wheels and pulleys. It’s going to wear out faster if it’s too loose or too tight. And then there’s how long they last. So maybe the less expensive belts save money up front, but if they break like this one just has done then I think it is still best to invest. That means more stops and more work to change them. BEDROCK belts live longer, saving money over the long term. Sometimes, belts are made with additional layers or coatings that help prevent oil from getting on them more effectively. These are good for extremely oily types of areas. Finally, inquire whether the belt company provides assistance or guidance. At BEDROCK we assist our customers in selecting the proper belt for their machine. We want you to get a belt that can perform right, last long, and not hurt your clutches or machines. Picking the perfect oil resistant conveyor belt for your business will protect everything you have spent time and money on, keep your machines functioning well, and take the long view of what makes economic sense. It’s a wise buy for any heavy-duty task. For specific applications, our Customized Chevron Conveyor Belt Highly Durable Conveyor Belt for High-temperature Materials is an excellent choice.

When it comes to strong oil resistant belts, you need to know where you can get them. Oil resistant belts are special belts that navigate in machines and have frequent contact with oil or other liquids. These belts have to be strong enough not to snap or get damaged by oil. And when you are searching for these belts, you need to make sure that the company knows a lot about creating belts that last long and work as good in an oily environment. One excellent decision is BEDROCK, which sells the highest quality products around in wholesale oil resistant belts. BEDROCK ensures their belts are constructed from proprietary materials that would not break down easily when exposed to oil and heat. Purchasing from a company with integrity like BEDROCK assures you quality belts that continue to run your machines smoothly. When you buy wholesale, it also means that you can buy in bulk and purchase many belts at a time which accommodates factories or shops requiring multiple belts. It also saves you money because the larger quantity you purchase, generally the cheaper each belt ends up being. You can source these belts from the BEDROCK website or contact their sales department. They can help you select the right belt for your machine, and let you know prices and delivery times. It is a must to provide information about your type of machine and exactly where it will be used so that they can recommend the most suitable oil resistant belt for you. Remember, when you buy belts from a trusted brand like BEDROCK, you can have confidence that your products are tested and carefully constructed. The wheels of your machines stay balanced, and you can prevent issues associated with weak or damaged belts. So when you need oil resistant belts, search for a company which will have proven high tensile strength belts available in bulk, such as BEDROCK. This will help you get quality belts without having to wait and keep your machines running hassle-free.

Oil resistant belts are great but they can also have their issues. The familiarity with common problems and their solutions can make machines live a long life in continuing good health. The belt may also slip or lose traction easily. That’s when there is not enough tension on the belt, or when oil seeps in between the belt and the machine parts. To remedy this, you’ll want to check the belt tension often and ensure it’s tight enough. Clean the machine parts to remove oil or dirt can also improve the friction of the belt. A further disadvantage is that the belt breaks or cracks after a period of time. Cause Even though oil resistant v-belts are designed for use with oil, a very old belt or a belt in hot locations will start to wear. To remedy this, bring a new and reputable brand of belt system such as BEDROCK into the picture. Quality belts make all of the difference and it's easy to see they last longer. Belts may be noisy or make weird noises sometimes. This can occur if the actual belt is rubbing up against something it isn’t supposed to or perhaps it just isn't straight. Fixing this entails reviewing the machine’s components and ensuring that everything is properly aligned. If there is something wrong with the belt, replacing it with this all new oil proof belt from BEDROCK will decimate the noise and assist the machine run in silence. Belts can also stretch so much that they stop working properly. This is if the belt is used for to long or if it is not the right size for your machine. To combat this, always use the proper size belt and monitor it regularly. If the belt appears slack or is worn, replace it promptly. Frequent care and inspection helps maintain the belts in good condition. With our belts from BEDROCK, you get a belt that is strong and designed to withstand oil, heat and wear. This reduces the odds of issues and makes machines perform better. Therefore, with proper care of the belt and machine, and replacing belts when necessary, you can solve virtually all issues with oil resistant belts.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.