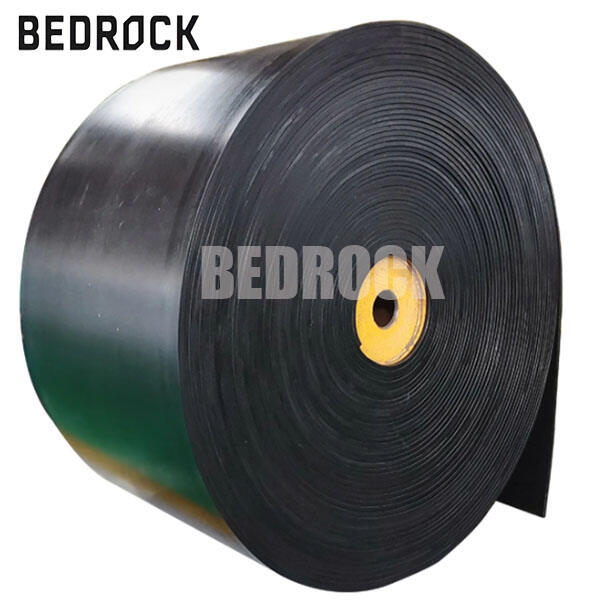

Marble conveyor belt The marble conveyor belt is the most important tool of factories and construction sites that makes you transport faster and safer than before. These belts are used to transport marble blocks or slabs without being broken or scratched. The marble conveyor belt has to be strong and robust because, as we’ve said, all the parts are made of wood. Here at BEDROCK we want to ensure that our belts are both rugged and smooth, so marbles simply roll out of the way! The right kind of conveyor belt can help workers get their job done more quickly, and also keep the marble looking as good as possible. It may sound simple, but picking the wrong belt can mean delays or worse, damage to costly marble items. So knowing how to work with marble conveyor belts will save time for people using particularly lumbering amounts of marble. For more options, consider our EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling.

Choosing the correct marble conveyor belt when purchasing in bulk is about more than cost. Lots of things can matter, including the belt’s material, size and how strong it is. For instance, if belt is too thin, it may tear while conveying heavy marble stones. On the other hand, if it’s too thick you might have trouble moving. At BEDROCK, we lean toward rubber or PVC belts which are strong and also gentle on the marble. And consider the belt’s width as well. Larger marble pieces can be carried by wider belts, but may require larger machines to function properly. Another concern is how the belt does with inclement weather or dust, if the marble is outdoors. Some belts also have reinforcement cushions to protect them from sun or rain and it’s a good thing. Every now and then, the speed of the belt slips a buyer’s mind. A fast belt can handle more marble, but could also slip or break things if not designed correctly. BEDROCK’s belts are engineered with the right balance of speed and safety, so marble remains safe even as its riders can fly. If you’re purchasing wholesale, it’s wise to see if the supplier provides support or replacement parts (since the belt can break or wear away). A lot of customers say that fast help has saved them from a whole lot of headache. Finally, consider how easy it is to clean the belt as marble dust or dirt may accumulate. Our belts have surfaces that are not dirt retentive, meaning cleaning is much faster. The best marble conveyor belt is one that considers all these tiny details, not just the type.

Wholesale Marble Conveyor Belt Suppliers You Can Trust Searching for the perfect supplier of wholesale marble conveyor belts could be a real hassle.

It is challenging to get a reliable marble conveyor belt supplier since not all vendors can cater to the needs of marble transportation. To discuss what you consider the standard for ‘on schedule.’ At BEDROCK, we feel that reliability is more than shipping products when it was agreed upon. It is knowing the products work days after day. Top-end suppliers have a lifetime of experience serving marble industries and they can tell you why some belts work better. There's one method of finding reliable suppliers is make sample order or go to their factory. It can be telling to see how belts are made or abused. Also, verify if the supplier provide warranties or guarantee. That tells you they believe in the strength of their product.” Some manufacturers give recommendations about how to install and maintain the belts; this is a great help especially for large marble factories. BEDROCK is constantly there for you with help and speedy delivery — even for large quantities. Another important factor is communication. Good proof suppliers will respond to questions clearly and promptly. When suppliers take too long to respond, buyers get irritated or when the answers are not clear. Suppliers listen and help solve problems Build trust. Finally, seek out suppliers who will be able to provide you with different kinds of belts as marble work can vary. Options, he said, mean you don’t have to discover new vendors every time your project changes. Bedrock provides marble conveyor belts to meet the specific product and customer requirements. So a good supplier search is about finding someone who cares about your business, not just selling belts. It’s that sort of joint venture that makes marble projects run smoothly and grow in time.

Marble conveyor belt is very important in the stone engineering industry. Marble is heavy and fragile. Once it’s ashe stone has been extracted from the earth, it has to be handled gingerly so that cracks and damage are avoided. That’s where marble conveyor belts come in. These belts assist in the movement of large marble blocks or slabs inside factories, or from one processing plant to another. Without conveyor belts, workers will have to lift heavy pieces of marble by hand or use machines that could damage the material. This can slow the work and make it more likely that you will break the stone. That is where BEDROCK’s marble conveyor belts come in, which can help to transport these heavy rocks they move as swiftly and safely as possible for an overall smoother operation. The belts themselves are strong and safe for marble’s surface. They also ensure the marble stays clean by shifting it in a manner that prevents dust and dirt from settling on the stones. Conveyor belts are also how stone factories save time, since no one needs to be running around with lots of pieces of marble at a time.” This means one can process more marble per day. In addition, the belts help to improve worker safety by minimizing heavy lifting. In a word, marble conveyor belts are indispensable tool in stone processing industry as it can protect the stone when work and make the operation more efficient as well as keep workplace safety. BEDROCK’s belts are created to withstand such challenges and help stone manufacturing companies keep things moving. This is precisely why you will find that every plant for processing stone uses superior quality of marble conveyor belts to get the job done. For more durable options, check out our Durable Steel Material Natural Rubber Conveyor Belt for Cement Industry and Construction Conveyor Use.

When individuals or businesses do a lot of work with big stone projects, purchasing marble conveyor belts in bulk, or wholesale, can be very smart and financially sound. Big projects require many conveyor belts to transport marble blocks all around the site of works or factory. Belts cost a lot of money if you buy them one at a time and they take forever to get. But when you stock up on wholesale belts from a reliable brand like BEDROCK, you’re getting a much better cost due to the fact that your belts are being sold in bulk. This is the cost per belt that you bought at a lower price. Plus, when you buy in bulk you have plenty of belts to keep a project motoring along without having to stop for more supplies. This is what allows large projects to complete as quickly as they do on time. Secondly, wholesale marble conveyor belts are cost-effective since they have a long sustainability. BEDROCK’s belts are constructed with durable materials that can hold up as you repeatedly move heavy slabs of marble every day. That also means you don't have to replace them that often - for much lower maintenance. The belts are also easy to clean and repair, if necessary, reducing the cost of replacement. By utilizing wholesale marble conveyor belts, companies have the option to tailor the belts to their needs. BEDROCK has various sizes and styles of belts available to fit many projects. So you don't waste money on belts that aren't right for the job. On the whole, there are many benefits to purchasing wholesale marble conveyor belts and some of these include saving money on overall cost, lower rates, quality that lasts and a fit for the job. When you choose BEDROCK for wholesale belts, you are saving money and keeping business moving in large stone processing tasks.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.