Heavy duty conveyor belts are what makes things move in factories and mines. These belts bear the weight of large volumes of such materials as they move without breaking or slowing down, so there are many other implications for their mechanical properties. We at BEDROCK specialize in making conveyor belts strong and durable. Our belts are tough enough for big jobs, day after day. Heavy duty conveyors don’t just enter your mind as a belt. It’s built with special materials and it’s well-designed to work well even in the hard places. The folks at BEDROCK understand what it takes to make a belt that makes machines run right and users stay safe. Those who are buying in large quantities for industry applications need to choose the right manufacturer as belt quality can affect how well their entire system works. And it’s not about just buying a belt anybody can buy a belt, but one that suits the task at hand and stands up to heavy work

Solid conveyor belts require solid qualities towards make it through requiring function. Very initial, stamina is actually a should. The belt needs to birth remarkable tons, will certainly certainly not extend or brake. Rather, it depends on levels of hefty material as well as major rubber or even synthetic material towards build belts that will not twist under stress. The 2nd, use protection is very essential. These belts versus rough materials all the time rocks, state, or even steel components. The belt surface area can easily use down rapidly as well as lead to mishaps or even a stop in manufacturing. That is why the leading is actually typically created thicker or even dealt with along with unique coverings to always keep it coming from wearing out. Versatility matters, as well, as belts need to traveling easily about rollers and pulleys. A belt that is actually as well rigid can easily break or even damages the devices. BEDROCK strikes a cautious equilibrium in between stamina as well as versatility to always keep belts running strong. Another particular is actually warm protection or chemical protection which differs along with the location of use the belt. In warm, dirty factory atmospheres along with warm products or even destructive chemicals, the belt has actually to prevent up under severe problems. Some belts are actually created along with extra levels of material or even unique rubber to withstand these risks. The belt surface area should be actually durable sufficient to always keep products in position as they travel along the belt. This assists preserve a consistent process as well as prevent squander. The belt is actually also thicker or even thinner, as well as larger or even narrower, depending upon the job. Hefty loads typically need thicker as well as larger belts. BEDROCK comes in various dimensions towards satisfy the differing commercial requirements. Sometimes, belts include unique styles such as cleats or even sidewalls towards help along with the transport of loosened or bulk products up slopes in addition to on slopes

Heavy duty conveyor belts are crucial for the transportation of heavy goods in industries such as factories, mines, and construction sites. However, when used enough, these belts can develop some general issues. One major issue is wear and tear. Because of these heavy rough and uneven materials belts are liable to suffer from cuts and wear. Another issue is belt slip, which is when the belt slides along instead of running smoothly. This can occur when the belt is not snug, or when the surface is slippery. Sometimes belts can also be misaligned, so they don’t run straight on their rollers. This is excessive wear, and the belt may not operate correctly as a result.

Companies such as BEDROCK certainly endeavor to address these issues by producing thick and durable belts. They are made of materials that withstand heavy weights and the abrasion of blunt surfaces. For instance, they add thick layers of sturdy stuff or steel into the belt so that it can keep going for long. BEDROCK also features belts with a grip that prevents slip and so the belt runs smoothly even in high loaded condition. In order to avoid such mistakes, they test the belts with diligence and create guides or tools that help them keep track of where the belt is supposed to be. Manufacturers also offer advice on keeping the belts clean and properly maintained. This is good because this helps belts do better, and it helps them last a lot longer. By addressing these common problem areas, BEDROCK’s heavy duty Conveyor Belt stand up to the test and continue working for you with very little down-time!

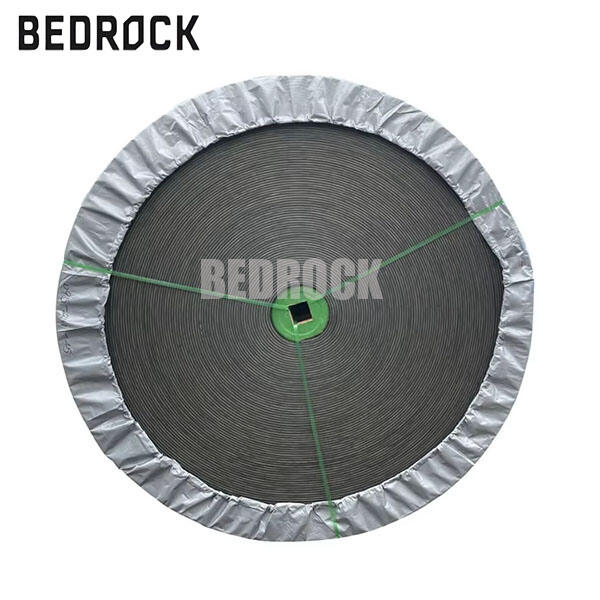

There are various types in heavy conveyor belts and each suited to the work as you want it. BEDROCK produces belts designed to meet the needs of a variety of industries, from mining and farming to manufacturing. There are mainly two kinds of conveyor belts, such as steel conveyor belts and nylon conveyor belts. This is the belt with steel wires inside, very strong. Purpose It is outstanding for long distance work while carrying a heavy load. Steel cord belts are preferred in mines because they can hump loads of rocks and minerals long distances without breaking. Another is the cloth belt. This belt is lined with layers of sturdy fabric, so it’s lighter but still rugged. Fabric belts are sometimes used in factories which have relatively light work and it is desired to save in the initial cost of the conveyor.

Some belts also have a special cover to resist heat, oil or chemicals. For instance, if a factory that processes hot materials comes to BEDROCK, belts that can withstand heat without melting or breaking are precisely what we produce. Other conveyor belt are produced to be resistant to oil or chemicals, and this is necessary where such substances would spill onto the belt. There are also belts intended to function in wet or cold environments. BEDROCK provides belts with covers that prevent water from penetrating or belts which remain flexible in cold temperatures. Selecting the correct belt type is critical to ensuring that your machine operates optimally and provides the longest possible service life. By knowing the needs of its client and providing the best solutions for all different trades in industry on belt selection, BEDROCK work for help its customers.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.