A brick plant belt conveyor is a key product in the process of making bricks. It helps to transport things around the factory. Envision a long, flat structure that transports clay and bricks. It’s what makes everything go faster and easier. Without the crane, workers would spend much of their time heaving about heavy materials. We at BEDROCK know how important conveyors are to a brick plant. It’s the reason we design our conveyor systems to be ultra rugged, and provide high performance. This article focuses on how to choose the right conveyor belt for a brick plant and how to get the most out of these extraordinary machines.

Efficiency is critical when operating a profitable brick plant and no where else is the importance of that more crucial than your conveyor belt. One important way we can help make this happen is through technology. Such as conveyor belts where smart sensors can be attached. So those sensors feed into the system, tell us, “Everything is working fine. If it does go wrong, they can also warn workers before a potentially larger problem occurs. This paves the way for less downtime and simple repairs. All can concentrate on production.

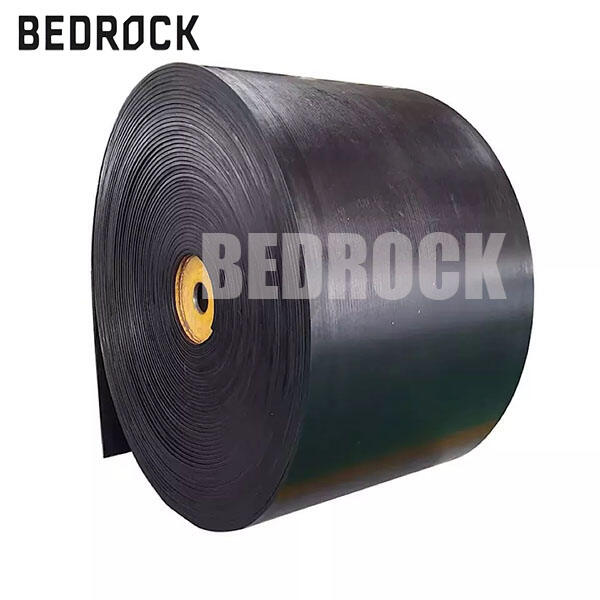

Selecting the correct conveyor belt for your brick plant is crucial. A quality conveyor belt can make your job easier and enable you to generate more bricks. First of all, consider what size bricks you want to make. Bigger bricks are heavier than smaller ones. And so you’ll need a stronger belt if you want to bring larger bricks safely. Also keep in mind how quickly you'd like to move those bricks. If you have large numbers of bricks to produce in a short time period, then you need a faster conveyor belt. But don’t forget, fast isn’t always best; the belt must also be strong enough to carry the bricks without dropping them.

Next, you will want to know what types of materials your conveyor belt is going to be handling. Some bricks are still scorching when they’re taken out of the kiln, and you want a belt that can tolerate high temperatures. If your bricks are wet, on the other hand, you’ll want to find a belt that won’t get slippery or damaged. You should also consider how long you would like the conveyor belt to last. Longer-wearing, high-quality belts are worth their higher price tags in the long run because you won’t have to replace them as often. For instance, a High Temperature Conveyor Belt is essential in this scenario.

Yet another is the condition of your brick plant. If your plant is dusty or dirty, you’ll want a belt that doesn’t have too much surface area and one that’s easy to clean without it being easy for it to go bad. And last you should pay attention to the conveyor belt price. Though cheaper belts may appear more attractive at first, they are not necessarily the most cost-effective once they break and result in more expensive repairs down the road. Don’t forget to ask for assistance from specialists such as BEDROCK when it comes to the ideal conveyor belt tailored for your requirements. They'll be able to give you a tip after about two league decades.

Regular maintenance can also improve the longevity of a conveyor belt. Regular maintenance may include occasional inspections of the belt to see if it is wearing out or damaged, catching small problems before they turn into bigger ones. Regular cleaning will also ensure that the belt is not neglected. When a company, like BEDROCK, provides customers with a conveyor belt it often comes with instructions for maintaining that piece of equipment. Observing this advice will ensure that you get maximum wear from your conveyor belt. Don’t forget, a stronger conveyor belt means less downtime and more time making bricks!

The brick plant belt conveyors are a great part of the process, helping to do things differently than making it by hand. These belts and conveyors aid in quickly moving bricks from one part of the plant to another. Moving bricks faster is a sign that the production line is fucking quick you know. That’s a good thing, because fast production means you can keep up with customer requests for the bricks and beause they will want their builiding -- or whatever it is — all in one piece by the end of this year. And with a conveyor belt, workers don’t have to manually lift heavy bricks, which both saves energy and keeps the work environment safer.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.