Belts are big in transportation, moving things from one place to another in factories and warehouses. They efficiently transport boxes, parts or even bulky items. Consider a colossal mechanism that never grows weary, forever toiling to keep everything turning. And that’s what a transportation belt does. At BEDROCK, we create these belts big and strong for those heavy duty jobs that are always on the move. It’s not enough to move stuff, it needs to be done safely and without incident. People depend on these belts every day, even if they don’t realize how essential they are. But when a belt breaks or goes wonky, everything can come to a screeching halt fast. That’s why it is really useful to know what makes a good belt and how to troubleshoot problems.

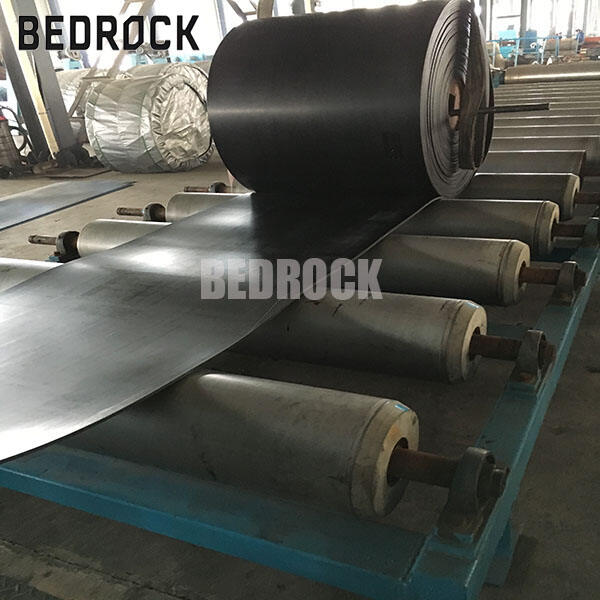

Hardy transport belts will carry loads of goods and continue to operate without breaking. At BEDROCK we are dedicated to building belts that last when your carrying heavy tools, sharp items or hot parts. And a key is the substance. Our belts have robust rubber and tough fabric material that are tear or stretch resistant. This means that it won’t easily develop holes in the belt or lose its shape. Another thing to consider is the edges of the belt. If edges are weak, jagged or frayed they can cause the belt to jam when fitted into the bonnet/housing and too much friction can damage the belt. BEDROCK ensures the edges are reinforced, so they continue to be smooth and strong. Sometimes belts need to be pliable, but tough. We engineer our belts to bend around wheels or pulleys without distorting, cracking, or losing grip. This keeps everything moving smoothly. And so, too, does the surface of the belt. Some need a rough surface to grip things tight, others need smoothness for slipping. We make different textures, according to what the customer wants. Weather and temperature resistance matter as well. In factories that get hot or cold, belts have to keep running without melting or freezing. BEDROCK patterns belts in a wide variety of conditions to ensure they won’t fail. Finally, the belt’s size and width determines how effective it will be. Thicker belts are more durable, but may be slower to use power. We assist our clients in selecting the correct size for their machine and reducing energy consumption. Building a belt that performs well and lasts a good long time is not easy to get right, but our years of experience mean we do just that. We hear what users need and create belts to fulfill those requests. For those looking for high-quality options, our EP Conveyor Belt is an excellent choice.

Transportation belts can be tricky, but if you know what to do, you can get them fixed quickly. Belt slipping is another most frequent problem. That happens as the belt moves too fast or too slow compared to the rollers. It is one of the things that can prevent items from doing what they are supposed to do. In general, slipping occurs when the belt is too loose or dirty. Slipping can be corrected by simply cleaning the belt and tightening it. BEDROCK recommends frequent monitoring to catch slip early. Another problem is belt misalignment. When the belt isn’t lined up right, it can wear quickly or even come off the rollers. This can delay and damage big time. Aligning is jargon for adjusting the rollers or belt guides to keep the belt in its proper location. Belts occasionally fall victim to cuts or tears from sharp edges or rough surfaces. When this occurs, the belt requires being repaired or replaced. Little cuts can be patched, but if it suffered major damage, replace the belt. Here at BEDROCK we are able to assist in helping identify the best possible repair as well as providing you with a sound solution with our replacement belt options. Tracking problems occur when the belt moves to one side rather than traveling straight. This could be a product of uneven tension or rollers that are worn out. Truing tracking is just to go through everything, adjust for good belt tension. Plus, belts stretch with time. When a belt stretches beyond its limit, it is loose and can slip or come off the track. The belt needs to be re-tensioned or replaced. Some also become worn out from heat, chemicals or dust. And, keeping the belt clean and using the correct materials can refrain from this. Resolving these problems rapidly saves time and money. BEDROCK understands how frustrating it is when a belt comes to a tool-grinding halt, so we offer tips and support to get things up and running quickly. Frequently, some maintenance — cleaning and tension-checking, in particular — ends up being what stops small problems from becoming larger ones. Those who keep an eye on their belts can ensure machines run longer and are never surprised. It’s not always pretty, but with help belts are strong and they work hard.

When purchasing transport belts in bulk you need to ensure that the quality offered is consistent. A conveyor belt moves things from one place to another in factories, airports and even on the street. If the belt is bad, it can snap or cease to function, which leads to big problems. Here are some easy steps to take before you buy high quality transportation belts.

The first is to always purchase from a reputable company like BEDROCK. BEDROCK is well known for crafting long-lasting, functional belts. One would hope that if you are buying something, particularly in large quantity, wholesale, that it is going to be of the same good quality from one time to another and you don’t have to worry about half of them breaking down twice as fast as the others. You can request samples from the outfit or even check the belts out before placing a big order. This makes it easier for you to check whether the belts fit your requirements. If you’re looking for options that are both reliable and affordable, consider our High Quality Cheap Price Rubber Conveyor Belt.

The tire factory is in the servce of great demand and a wide variety of transport belts is essential, must have to select under good with low price. Cost effective meaning the belts work great and are relatively inexpensive. When you’re manufacturing at scale and you need hundreds or even thousands of belts, purchasing them at a competitive rate means fast saving.

One key trend: using new materials. Belts of the past were generally of a retarded variety and simple rubber or fabric. Finally, companies use special plastics and reinforced materials that are stronger but lighter. It is these new materials which can make transportation belts last longer, and carry a larger weight without breaking.” BEDROCK takes these high-tech materials and turns them into belts that can take a beating.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.