Mining belts are essential equipment in the mining industry and are designed to transport rock, minerals, and other materials. These belts transport materials from one location to another, so miners can move more dirt and do it faster and easier. They need to be rugged as much of the work they do is very hard on equipment. At BEDROCK we are Other focused on building long lasting and great working mining belts in these toughest conditions. There are many types and sizes available, but selecting the right one depends on what type of mining you are planning on doing and how much material you need to move. Wearing the wrong belt can lead to problems like breakage or it might slow down your work, so you must know what makes a good mining belt before making a purchase. For instance, you might consider an EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling for enhanced durability.

Selecting the proper mining belts while purchasing in bulk can sometimes seem confusing but it is extremely important. First, consider belts manufactured of strong material such as heavy-duty rubber or reinforced fabric. These materials make the belts last longer and able to carry heavy loads without ripping. Consider the thickness of the belt, as well. Thicker belts tend to come with longer life and the ability to convey larger loads, though they also might be heavier and more expensive. Also the design of the belt. Some belts also contain special layers on the inside to make them more resistant to heat, water or even a sprinkle of gasoline. If you’re mining in harsh weather or over sharp rocks, seek out belts that offer those extra protections. Also take a look at the belt’s width and length. They need to fit the machines you use and they need to be able to carry the amount of material that you hope they can. There’s also the question of how well a belt grips or resists abrasion; one that slips can slow you down and lead to accidents. At BEDROCK, we design belts that are tough as, well… you know. But does this product deliver value to miners? When purchasing in quantity, try some belts on your setup first to see how they fit and work. Better to take some time checking than to be stuck with belts that break down or don’t fit you the way you need them to. Remember, quality mining belts cost no more to make than poor quality, they work better and last longer.

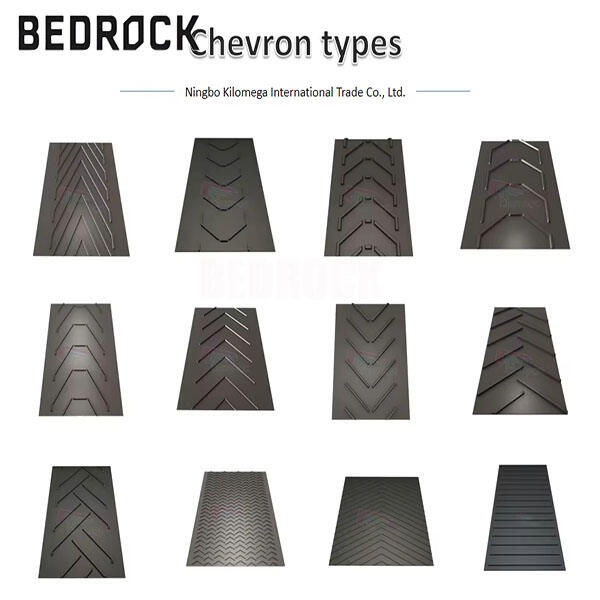

Choosing the best belts is only a part of the equation; you also need to choose a reliable belt supplier. You need a manufacturer that makes belts which are durable and meant to last the prolonged haul. Good suppliers will not only install the belt but also assist you in understanding what belts would work best for your mining needs. They often suggest sizes for belts, the materials that work best and how to make belts last longer. One such supplier is BEDROCK, who are recognised for their durable belts used in mining. See if the suppliers have good customer support when you look for them. You might need assistance with orders or questions post-purchase. And, of course, seek out suppliers who can meet your deadlines, particularly if you order in large quantities. Delays can hinder your mining efforts. Some suppliers have warehouses near mining sites, which can speed delivery. Price is a factor as well, but you don’t want to go picking up the cheapest belts with no thought to quality either. Cheap belts can wear out quickly and cost more in the end to replace. Inquire whether suppliers can supply samples or trial product. That way, you get to see and feel the quality of the belt before purchasing a large quantity. Finally, look for suppliers that offer guarantees or warranties on their products. That indicates they have confidence that their belts will do what it takes to get other people to trust them. At BEDROCK, we believe trust is the foundation of all business relationships and we ensure that high quality belts are our top priority to keep miners' equipment running efficiently. For high performance and durability, consider our Industrial Conveyor Belt Manufacturer Price, Heavy Duty Mining EP250 Chevron Rubber Conveyor Belt.

Mining belts are highly essential devices in mining tasks. These belts help move rocks, minerals and other materials from one place inside the mine to another. It’s even easier and faster when you work with mining belts. One major advantage of the mining belts: They keep some workers safer. And there are fewer chances for accidents among the miners when they don’t have to lug heavy loads by hand or use unsafe methods. Mining belts carry materials more easily, thereby reducing the risk of dropping heavy objects or getting injured. And, mining belts are built strong and durable to handle the rugged nature of materials and sharp rocks so that they don’t snap easily too. Viewers say this prevents accidents due to faulty equipment.

Beyond safety, mining belts also work to enhance the quality of performing mining jobs. Mining belts distribute materials in large quantities, quickly. This saves time and allows miners to do more work each day. Mining belts will work away all day without a break so mining becomes much more efficient. When they hum along, mining belts save time for machines and people that might otherwise stand idle waiting for a truck to negotiate the hundreds of kilometers of dirt roads on site in order to deliver tool platforms, oxygen containers or drilling equipment. The mining belt is good, the less likely it will fail or delay. This in turn means the entire mining project can be completed more quickly and less expensively. If you are looking for a reliable option, consider our High Quality Cheap Price Rubber Conveyor Belt 4 Ply 800mm Belt Flame Resistant Ep Conveyor Belt for your project needs.

If they buy in bulk from BEDROCK, companies pay less for each belt. This is a money saver because one belt at a time is usually more expensive. Also, purchasing new belts in bulk means companies don’t have to worry about running out while waiting for replacement belts. That way mining can carry on without the cost of lost equipment, they said. Apart from that, BEDROCK also believes in getting mining belts to you as fast and efficiently as possible–big projects lose minimal time.

Another development is the drive to make mining more efficient and sustainable. Mining companies hope to consume less energy and have fewer environmental disturbances while also pocketing more minerals. Higher level conveyer belts use material which has decreased friction, and will save power. They also have longer lifespans, meaning there are fewer belts to throw away, which is better for the environment. These trends are supported by the innovative products BEDROCK introduces to help mining operations work smarter and cleaner.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.