If you’re working in or around stone crushing, you understand how important a conveyor belt is. This system transits rocks and stones from one end to another and the whole process runs smoothly. We get how all aspects of a stone crushing plant work together. The conveyor is the system’s backbone. Without it, everything slows down. It is essential that you select the right conveyor belt to keep your stone crushing business operating smoothly. It can help minimize delays and guarantee your goods are transported smoothly. When it comes to choosing a conveyor belt there is much to consider, and so that’s what we are going to explore now.

Quality is the key factor when selecting stone crusher conveyor belts. What you need is a rugged conveyor that can handle heavy rocks without breaking. You’ll want to find a belt made of durable materials, like rubber or metal. Rubber is pliable but strong, so rubber construction is good when you have heavy loads. Metal may also be employed, but is generally reserved for special applications. The belt must be firmly held. This means it needs to have a rough texture, or even special patterns. This ensures that the stones do not slide off and fall down. Also, take note of the length and width of the belt conveyor. If it’s too short it won’t get you where you need to go. If it’s too narrow, you can’t fit enough stones in there; that slows things down.

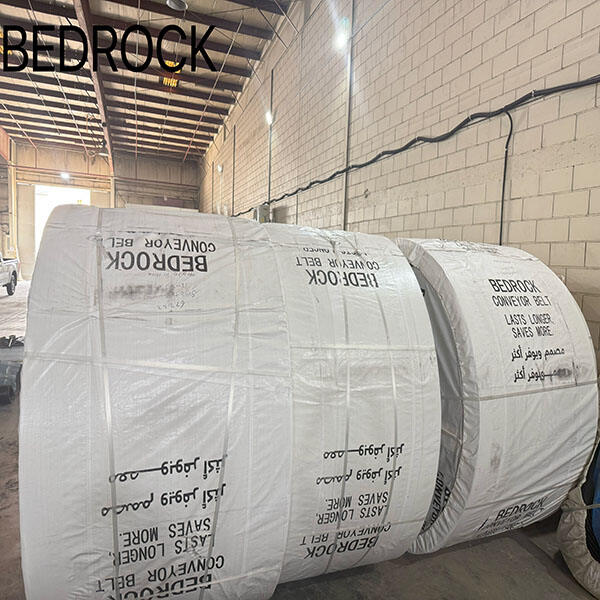

One of the reasons why a conveyor belt is necessary when crushing stone is it helps to speed up the entire process. When large rocks come out of a crusher, they need to be moved quickly or turned into useful material. If the conveyor belt is too flimsy it may rip or tear, and that slows folks down.” That’s why BEDROCK constructs conveyor belts from the highest quality materials to withstand the strain of moving heavy stones without issues. What’s more, a proper conveyor belt should be able to withstand the ravages of rough stones. If not built to last, they become worn out in no time at all and you find yourself needing repairs and losing production time. For those interested, options like the Rough Top Conveyor Belt could be considered for added durability.

Of course an excellent conveyor belt, in addition to the conditions already mentioned, has also be resistant to cuts at a stone crushing site. Dust, dampness and various elements can fade less expensive covers. BEDROCK understands this and that's why our belts are built to be equipped for the most challenging conditions. That way they can keep grinding in an unfriendly environment. So, if you are thinking of a conveyor belt for stone crushing, its good shape means it is in top condition and ready to help you get the job done. This ensures everything runs smoothly and efficiently, a key element to any stone crushing operation.

It is something you may want to take into Consideration When it comes to buying the right conveyor belt for the construction of your own stone crusher. BEDROCK specializes in belts that have something extra to make them the best for these kinds of hard work. Can have your signature belt Allegedly, one of the two best things about these belts is their strength. The belt would be made of rubber or steel and withstand the weight of heavy stones without breaking. This strength is crucial, as the stones can be heavy. The belt can break if it’s old and weak, choking off the whole operation.

Another key characteristic is that which is wear-resistant. Crushing of stones has sharp rocks, dust and heavy vibrations. Any good conveyor belt should be able to withstand these conditions without being easily damaged. This is why Kent shallow uses high quality, durable materials in their belts so that they last and require less maintenance. It's also essential that the conveyor belt has good friction. That's because the surface of the belt is what holds onto the stones as it travels. If the surface is too shiny, you can find stones slipping off it and that’s not good.

Finally, the best conveyor belts also offer ease of maintenance. It ought to be easy to inspect for any wear and tear, as well easy to replace if necessary. Not only is this a time and money saver in the long run. According to BEDROCK, however, a good conveyor belt is also flexible when it comes to integrating into various machine sizes. The flexibility accorded makes it to be used in many approaches which can be modified to suit evolving requirements. In general, if you need any conveyor belt for stone crushing application, you should deal only with a reliable manufacturer that can ensure up-to-standard quality. These top features come standard in BEDROCK conveyor belts to make everyone’s job more productive and hassle-free.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.