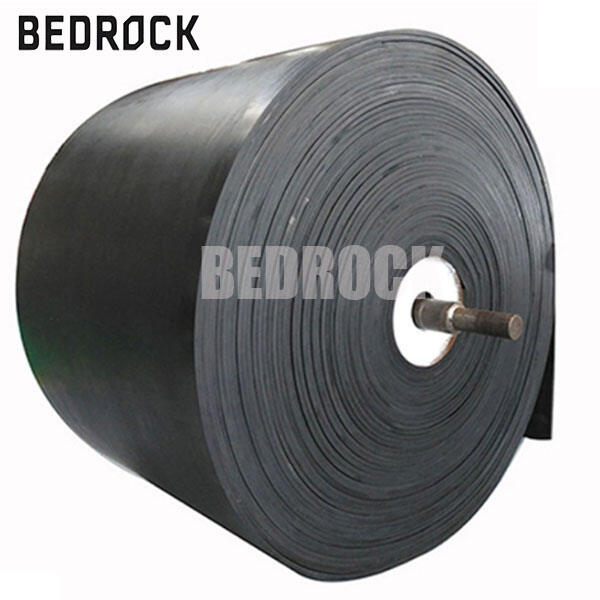

Conveyor belts are awesome when it comes to moving stuff in factories, mines and the like. They’re the ones who help products get from point A to point B efficiently, quickly. Of the four types of conveyor belts, abrasion-resistant conveyor belts are designed to withstand material wear from these items of heavy merchandise due to their durability. These belts are highly resistant to abrasion, which is key when you want everything in good working order at a bustling workplace. We know that conveyor belt solutions must be much more than run of the mill for our customers to receive true value, and we deliver on each and every one of their order.

It can feel like there are a hundred mountains to scale when you’re trying to choose the right abrasion-resistant conveyor belt. First you should know what materials will be moving on the belt. If you’re working with extremely abrasive material, you want a belt that is very tough so as not to be damaged. Find a belt that is crafted in heavy rubber or other hard-wearing materials. Finally, consider what size you will need. You want to measure the width and length accurately so you end up with a belt that fits your machine. A belt that is too large or small will not serve you well for your operations. Additionally, you might want to look into the EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling for optimal performance.

Also think about how simple it is to both set up and maintain your belt. With some belts there is no special tool required for installation, so you can save time when light trucks or vans are not in need of the extra grunt. And think, too, about where you are going to purchase from. A good supplier, like BEDROCK, will help you choose the best belt and provide guidance if you’re not sure. And finally, be sure to read reviews or ask other employees about their experiences with different kinds of belts. This may give you new perspective on what works best with your specific detox needs. When you take time to analyse the above points, it is then truly possible to source a conveyor belt that's right for your business and ensures smooth transitions at the point of production!

Conveyor belts are necessary in most warehouses and factories. They assist in the movement of goods and supplies from place to place. A conveyor belt resistant to abrasion is designed to resist being worn away whilst moving things like rocks or sand. And that’s significant, because when a conveyor belt breaks down, work is delayed and companies are out big money. With a strong chain that is not easily broken, about the movement of good things we can clink faster and safer. Picture a factory in which deluge of heavy materials must be hauled around each day. Alongside high-quality belts like those from BEDROCK, they can hold that workflow steady. This means production is able to roll without many hiccups. Consider investing in a High Quality Cheap Price Rubber Conveyor Belt to enhance your operations further.

And if a conveyor belt breaks, it can cause injuries. Workers could trip over, or drop a heavy item if the belt isn’t working properly. Abrasion resistant conveyor belts can act working on a tear as well as avoid costly replacements or alterations and remain lasting to all effects. They will be able to hold heavy weights and can work with rough surfaces (like in factories that involve working with stones, metals or chemicals). When companies select a heavy duty belt for their belt feeder from BEDROCK, they are getting a superior quality product that will perform to optimal standards while minimizing down time.

Maximising the lifespan of an abrasion-resistant conveyor belt Just like a regular one, your AR conveyor belting needs a bit of TLC to make sure you get the best out of it. Because as with a car, if you don’t take the occasional opportunity to maintain it properly, one day your conveyor belt will let you down. One of the best ways to help these belts last longer is by inspecting them frequently. Workers should check for any evidence of damage, such as cuts, tears or worn sections. It needs to be addressed immediately if they see something wrong. Spotting problems early on can save time and money over the long term.

There are numerous applications for industry that can make good use of the wear resistant conveyor belts. Mining is one of the most important industries. Materials such as coal, rock and ores must be literally moved from place to place in mining. Because these materials are both heavy and rugged, they can cause standard conveyor belts to break down fairly quickly. When mines have a lot of downtime due to repairs they are not making money so when this is minimized with BEDROCK wear resistant conveyor belts, the dollars generated do not go towards replacement parts.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.