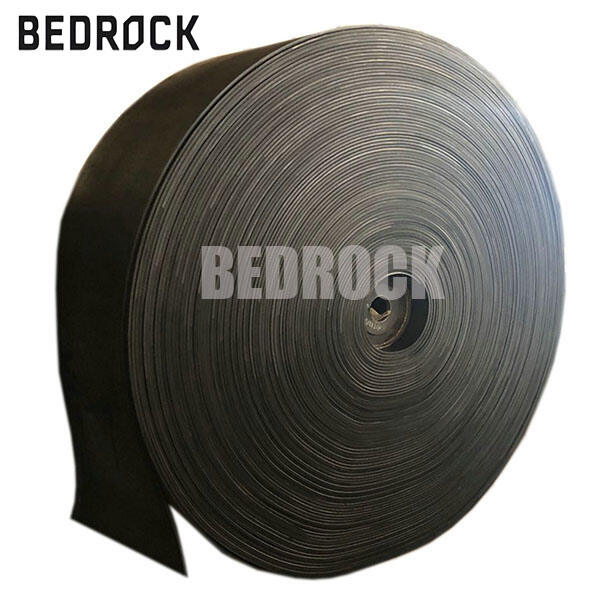

Wear-resistant conveyor belt is now an essential part in the industry and in mining. They are used to transport bulky materials from one end of a room to another. And companies that make such belts, like BEDROCK, have produced them sturdy and durable so they’ll hold up for a while — even when the going gets tough. This is particularly true of businesses in the mining, construction and manufacturing sectors where heavy loads and harsh materials can take their toll on a standard belt. These belts are made from special materials that can handle that kind of pressure, so the companies using them can spend less time waiting for replacement parts and more time on production. The right conveyor belt can help you save money over time because it won’t need to be replaced as frequently. For more information on durable options, check out EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling.

There are many good reasons for using wear-resistant conveyor belts in the “hard working” Heavy Industry. For one thing, they’re made to be durable. When mining companies transport ore or rock out of mines, they require a solid belt that can handle a beating without tearing. A decent conveyor belt will avoid the weight of large items while also protecting itself against any damage at the hands of jagged edges. In a coal mine, for example, the belt carries heavy lumps of coal rather than light kaolin. When that belt rips or wears out, there are big delays and money at stake. For businesses, time is money, so reliable equipment is super important. A great choice for such environments is the High Quality Cheap Price Rubber Conveyor Belt.

One other thing that makes these belts a must-have item is the safety. Conveyor belts can be hazardous when they stop. No workers would be hurt if they fell from the dust collector or had to work to repair a broken belt. The wear-resistant belt is effectively protected and the workplace is safer. That’s why companies should make sure that the belts being used meet high safety standards.

Highly abrasive resistant conveyor belts can also provide some added efficiency. The better materials flow, the better operations work. For instance, if you have a factory that’s producing things like car parts, a powerful conveyor belt will ensure everything gets moved along smoothly and with fewer stoppages. This means products can be made and shipped more quickly, and everyone is happy.

Another difference here is the ROI with respect to belts: by purchasing a high-quality wear-resistant conveyor belt---such as those produced by BEDROCK---companies can end up saving themselves money. The longer a belt can last, the more money a company saves on repairs and new equipment. So the decision to purchase a durable conveyor belt isn’t just smart, but it’s also in many cases imperative for heavy industry success.

For companies, selecting the best wear-resistant conveyer belt matters. And it can get overwhelming because there’s so much out there. But don’t worry! But if you know what to look for, this research becomes easier. Start by considering what you’ll be carrying on the belt. If your plant transports heavy metal parts, a belt that may be better suited for transporting light pieces of material such as paper or food products will not hold up to the harsh conditions.

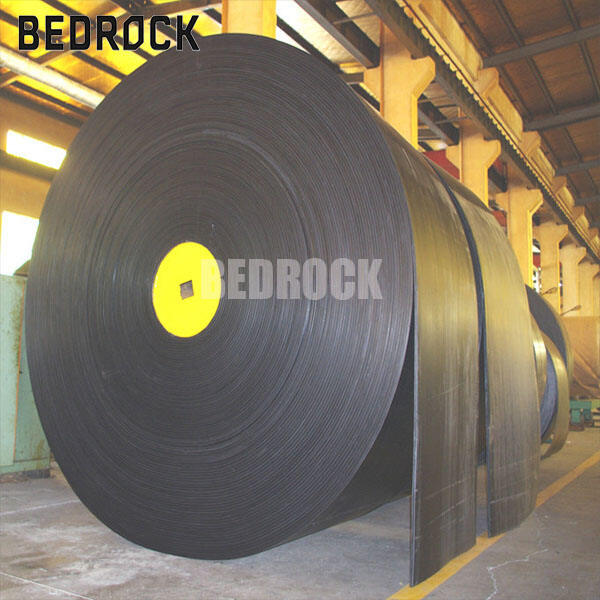

Wear resistant belts for example can also make a factory or production line more efficient. When the belts are strong and robust, everything moves faster and more efficiently. For instance, if a conveyor belt is able to support heavy loads without breaking, workers can be more productive in less time. That allows products to be produced and shipped out more quickly, which is really good for business. REDUCE DELAYS with BEDROCK wear resistant conveyor belts. When regular belts break, workers must stop work to repair or replace them. Not only does that loss time, it is also a loss in productivity. Unlike BEDROCK's thick belts the durable belts help to maintain a uniform flow. Workers can concentrate on their jobs without concern the conveyor will break down. These belts also contribute to energy conservation. Better belt function means equipment doesn’t have to work as hard. This saves energy, which is better for the planet and the company’s bottom line. With less failures, and a more efficient running, there is also an increase in overall productivity for companies. Happier, better working workers are those living in this far country where they can count on their equipment. It's a happy space where the best that everyone can do is encouraged. that have BEDROCK wear resistant conveyor belts installed can see an increase in up times of up to 286%, Production levels can also be increased by more than 25% as the conveyor belt will not need replacing as regularly, so running costs are reduced, Noisy conveyors will pass sound pollution tests and Tighter scrap metal/ product control is a double benefit.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.