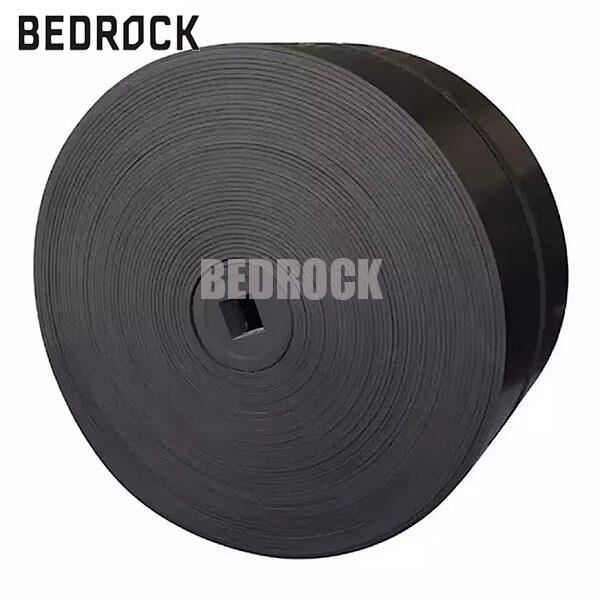

Abrasion resistant conveyor belt is a special type of belt which used in machines when it running the heavy and hard material. Those belts must be strong, because they get a lot of rubbing from things like rocks, sand and pieces of metal. If the belt isn’t rugged enough, it won’t wear well and will fail, leading to lost time and added expense. And that is the reason using a high abrasion conveyor belt ensures the materials convey in heavy, rough condition industry. BEDROCK manufactures these belts using sturdy materials to offer enduring performance even in difficult areas. Selecting the right belt can help machines run flat and save money in the long term. For instance, a Rough Top Conveyor Belt is ideal for transporting materials that require a non-slip surface.

High Abrasion Resistant Conveyor Belting – HARK FABRIC GRADING AND PERFORMANCE LIMITS * Cover Type Qualities and International Standards: TYPE QUALITY INTERNATIONAL STANDARDS IN PLAYING FIELD Low Abrasion resistance Elastomeric cover (resislient to wear) Medium to highly abrasive, nonscalping/ noncutting elastomeric covers A scale is provided specifically for such belts HR = NB 64π Return – 6 …

It’s not easy to choose high abrasion conveyor belt. There are a number of things to consider before buying one. To start, you need to know what type of material the belt will be moving. If it's jagged rocks and scratchy metals, then you require a belt from tougher-than-nails materials that are up to the job of blunt force trauma-induced slicing and dicing. For a softer material, the belt doesn’t have to be as strong. The strength of the belt is important, too. Thicker material may last longer, but it can be heavier and pricier. BEDROCK makes a variety of belts with varying thicknesses so you can find the best fit without burning a hole in your pocket. Another consideration is the surface of the belt. Some belts have nonslip surfaces to keep things from sliding off, while others are smooth so that materials move more quickly. Selecting the best surface depends on the job. Also take into account the temperature at which the belt will be operating. For very hot or very cold places, some belts are more suited to pass through, such as the Cold Resistant Conveyor Belt designed for extreme environments. We designed BEDROCK’s concrete breaking belts to work in a variety of harsh conditions, so you don’t have to worry about the weather or the heat. And finally, consider how frequently you plan to use the belt. If the machine is running for an entire day, the belt must be strong and sturdy. If it runs only occasionally, a cheaper belt may be O.K. The way it from my experience, many of the customers regular BEDROCK belts as they balance between cost and sturdiness/grace for serious work. It is wise to consult with experts before you buy, so that you find a belt best suited for your needs.

Where to Source Durable High Abrasion Resistant Conveyor Belts in BulkIf you are looking to procure various types of high durability conveyor belts with coating possible for your bulk orders, check out this URL;

It is not all the time when you will come across durable high abrasion conveyor belts wholesale. Lots of suppliers sell them, all belts aren’t designed to be put through the ringer. BEDROCK provides an option for bombproof belts, built with hearty materials and ingenuity which fair wear and tear better than your average belt. Purchasing from a reputable source such as BEDROCK you will get belts that have been tested and proven to work with heavy abrasive materials in them. Purchasing Wholesale When you make a purchase from wholesale, sometimes you can get better rates, especially if you need a whole lot of belts for one project. This also saves money and keeps your machines running without frequent repairs. Plus, when you buy from a factory as I have done at BEDROCK you can get belts made to YOUR requirements. Maybe you’re looking for a belt that’s a special size or one that can be used in extremely hot factories. BEDROCK can build belts that are ideal for your work. Some of them don’t last as long, because they are made of cheap material or don’t check quality meticulously. That creates all kinds of problems, and it’s more expensive in the long run. I have had customers move to BEDROCK belts and never think about belt damage months or years down the road. And, BEDROCK provides recommendations and support in case you have questions about selecting or using belts. Therefore, if you are in the market for strong conveyor belts that will last at fair prices, searching for wholesale deals through BEDROCK is a good place to start. The point is not that any belt will do, but that you need the right belt to keep your work running smooth and your machines safe!

High abrasion conveyor belts are especially important in the mining industry, where heavy materials such as rocks, coal and ore can travel long distances quickly and safely. These belts are strong and durable-in-use, even in challenging applications due to their key characteristics. The hard surface of the belt is a critical aspect. This surface is of special rubber or other quick-wearing material. Mining materials are rough-edged and abrasive in nature, so the belt has to be tough enough to withstand abrasions and cuts. Another major feature is the belt’s heavy-weight capacity. Mining materials can weigh a lot and the belt must have enough strength to handle large loads without breaking or stretching. This is because high abrasion belts are full of more layers on the inside which will provide extra support and strength. The layers are usually constructed of strong materials such as steel cords or sturdy fabrics, which help the belt remain strong yet flexible. It also needs to be flexible enough to move around pulleys and rollers without cracking. Furthermore, the high abrasion conveyor belts can grip well. In other words, the belt can retain the materials without allowing them to slip or fall off, which ensures safe and smooth working. Last but not least, these belts can stack up in various weather situations. The belt whether hot, cold, wet or dry should maintain its rigidity to ensure it doesn’t become either too soft or hard. We ensure our high abrasion conveyor belts do too, with the quality of our manufacturing trusted by many industries. We concentrate on working with robust materials and intelligent designs in order to assist the mining sector achieve good results. Our belts are very durable and cut their way through too many repairs or replacements. This both saves money, and keeps mining work on schedule. Opting for BEDROCK high abrasion conveyor belts is a guarantee that their materials will be transported safely and efficiently day in, day out.

Bulk transport systems transfer vast quantities of weighty materials from one location to another. Such systems are of critical significance to sectors such as mining, construction and manufacturing. High abrasion conveyor belts are a major part of making these systems work better and faster. One reason these belts are more efficient, is they last a very long time compared to standard type of belts. Since they are more durable, they don’t need as frequent replacement. A machine is never down for repairs, which means that the work continues without any interruption. An infrastructure that is down less time can move more material in a shorter period, saving money and allowing companies to achieve their objectives. High abrasion belts also help with the smooth and safe transportation of materials. Their solid surfaces and great grip prevent materials from slipping or falling. This eliminates waste, preventing a mess in the workplace. When you lose less material, companies save time to achieve superior results. Plus, they’re strong enough to support heavy loads without breaking or stretching. That means they can carry larger amounts at a time, while the whole transportation process speeds up. The structural construction inside the belt also helps it maintain its form even after hours of running. That allows businesses to plan their work better and prevent surprises. At BEDROCK, our high abrasion resistant conveyor belts are built to last and perform. Designed with unique materials and construction to make belt rugged, strong, and durable. Our belts also function well in a wide variety of machines, and are capable of handling all varieties of heavy material. By choosing BEDROCK belts, companies will have fewer headaches and better results. This makes it easier for workers to do their jobs and helps companies save money. After all, when it comes to the final product, high abrasion conveyor belts from BEDROCK make bulk material handling systems faster, more reliable and serve your heavy duty plant operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.