A quary belt is very essential for minning and heavy material movement. It’s a strong, wide band that moves big rocks, small rocks, sand or other heavy material from one place to another inside a quarry. Quarries are where people go to dig out the rock and minerals from the earth. There would be no fast or easy way to move these heavy materials without a quarry belt. The belt is what enables workers, and the machines they operate, to keep the materials flowing smoothly — so work doesn’t stop or slow. At BEDROCK, we cater to help ensure you get the toughest and most durable tools out of your belt because we know they take just as much abuse and pressure that comes with the territory. Belts also occasionally snap from being poorly made, or they wear out quickly, slowing the entire mining process down. So, the proper quarry belt is essential for anyone in this industry involved in mining and construction. For more information on durable options, check out our EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling.

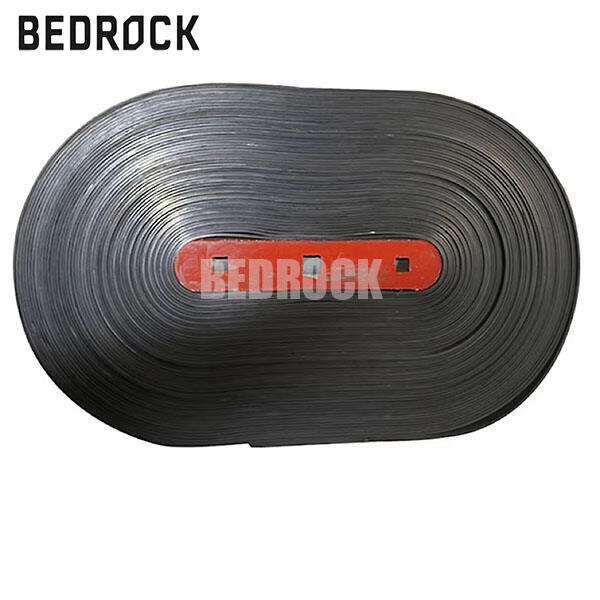

A quarry belt is a giant, loop that is created out of highly durable materials such as rubber and various special fabrics. It carries heavy things rocks and sand, gravel or coal in mines and quarries. Imagine carrying enormous rock piles by hand —those would be very time consuming and energy-draining. The wheels can help, but quarry belts make the process even simpler by allowing enormous loads be moved quickly and safely. This is known as bulk material handling. Without a belt, machines would have to be stopped frequently, or workers would have to rely more on trucks and shovels, both of which take time and money. A good quarry belt should be made tough against cuts, tears, and hazards such as sharp rock or large drop-offs. Here at BEDROCK, we understand that these belts do more than hold up your pants – they act as an extension of who you are. Belts can sometimes become wet or endure hot sun all day. Our quarry conveyor belts are largely used in this industry, which grow the habitat of wear and tear. One is when a quarry belt, which transports massive rocks from the digging spot to crushers, breaks down; all work stops until it is repaired. Which is why a belt that can be on the clock 24-7 is mandatory. Using a quarry belt can save you money, time and make your mining a safer process. Problems, even a little one, anywhere in the belt can lead to major headaches, so it is important have sturdy ones that they know will keep things turning smoothly.

It’s difficult to choose the right quarry belt since there are lots of varieties and sizes. BEDROCK always suggests to customers they figure out what exactly it is they are carrying and how much weight. For instance, if the materials are sharp stones or rocks, the belt must be especially resistant to cutting. If it’s largely sand or loose gravel, you want something with a smoother belt. The thickness and strength of these layers in the belt is important. Some belts have steel cords inside to give them strength, others use layers of fabric for flexibility. For heavy-duty mining, steel-cord belts are the ideal choice, as they allow for heavier loads to pass through without breaking. But they’re also more expensive, so it comes down to the budget as well. Another consideration is the speed and width of the belt. A wider belt can handle more material, but it requires additional power to operate. Also, the belt surface would need to be designed to grip material well so rocks didn’t fall over the sides of the belt.” BEDROCK consistently works alongside our customers to choose the best belt for their particular application. And while there are variables, some based on the weather where the quarry is located — that’s because some belts do better in cold places than hot ones — it’s dirt cheap. In a desert mine where the sun is shining down, the belt shouldn't become soft or melt on account of it. In cold mines, it has to remain flexible and not crack. Maintenance is also important. If you have a belt that is easy to clean and mend, this will save your sanity. Some quarry belts are made with special covers or layers that prevent dirt or chemicals from adhering to them and make for a longer-lasting belt. So when selecting quarry belt, it’s really about striking the right balance between strength, durability and price. We're proud that you can find our belts at work - from farming to coal mining, to logging, timber cutting and construction. We know you work hard and endure the worst of conditions and we go to great lengths in order to make belts that won’t quit. If you're looking for quality options, consider our High Quality Cheap Price Rubber Conveyor Belt 4 Ply 800mm Belt Flame Resistant Ep Conveyor Belt.

By quarry belts we mean special conveyor belts in places called quarries. Quarries are large, open pits in the ground from which rocks, stones and minerals are extracted. In such places you need strong and tough belts, capable of carrying heavy materials without getting damaged. A strong quarry belt is being built to do the hard, heavy work in these difficult places. One is size, another strength. And every day the belt must carry heavy rocks and pebbles along without tearing or stretching. BEDROCK quarry belts are reinforced with super-strong material that will hold up to the weight and never sag! Also, the resistance to wear is an important property. Quarry belts never cease to jostling sharp stones and harsh surfaces. If the belt wears too quickly, it needs more frequent replacement, and that is a waste of time and money. Special surface on BEDROCK belts that resists early wear, even in worst conditions. Then the belt should withstand extreme heat and cold. It tends to be rather warm in the quarries in summer, and rather cold in winter. BEDROCK QUARRY belts are designed to perform well in hot or cold weather without becoming weak and cracking. And the belt has to stand up to water and mud. At other times, the quarries can become wet from rainfall or from water used in the mining process. A quality quarry belt like the one by BEDROCK is not going to be ruined by water or mud and WILL keep stuff running as it’s supposed to. Finally, the quality quarry belt can be easily installed and maintained. If the belt gets dirty or torn, it can stop running and slow the whole quarry down. BEDROCK belts are also easy to clean and repair, ensuring that workers can get the quarry operating again. All in all that is what makes the BEDROCK quarry belts the best going choice for demanding quarry jobs.

Large purchases of quarry belts are expected by companies that operate quarries. Quarry belts are utilised on a daily basis, so it is crucial that they’re of high quality. When purchasing in bulk, one wants to be certain they are getting the highest quality belts that will last as well as perform. For one, you might want to take a closer look at what the belts are made of. Strong-grade, rubber and fabric constructed quarry belts are compounded to the bedrock formula for long life; a fabric with high strength can be tested before purchase. This ensures that the belts are able to hold heavy weights without snapping. Then it is critical to consider the construction of the belts. Decent-quality belts are made with strong layers inside, called plies, to keep everything together. Special machines and workers that know how make strong plies do not come apart easily belts for Bedrock. Also, prior to purchasing numerous belts, purchasers should request samples or try out belts. That way they can observe firsthand how well the belts work in actual conditions. BEDROCK does testing and samples, so that customers know they’re getting the right product. Another way of ensuring quality is by considering the reputation of the company. We’ve been cranking out reliable quarry belts for a long time, and customers know that if you come to us you’re going to get good product. Buyers should also check for guarantees or warranties on the belts. BEDROCK offers warranties that assure the belts will survive for a specified period and, if there is an issue and it’s the company’s fault, they will help fix it. It’s also wise, when purchasing large quantities, to inquire about delivery and storage. BEDROCK ensures the belts are bundled safely and sent on their way, with recommendations on storage to ensure they remain in prime form. Lastly, buyers need to maintain good records on whatever they buy and then frequently inspect the belts after being received. Customers can consult with BEDROCK on proper maintenance to keep the belts strong and safe during their use. Adhering to these procedures and selecting BEDROCK quarry belts will help them ensure they receive high-quality products that keep their quarries running smoothly. For even more options, explore our Customized Chevron Conveyor Belt Highly Durable Conveyor Belt for High-temperature Materials.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.