Stone conveyor belts are how frequently heavy stones and materials in mines, quarries and construction sites are transported from one place to another. This belts are well made, so it can support heavy and sharp stones without breaking or wearing out too quick. Bedrock makes long lasting and quality stone conveyor belts to fit any need, even in those harsh conditions! Stones can be placed in these belts and they will take them directly to the desired location without problem. Without them, the work of moving large quantities of stone would laborious and slow. And so, stone conveyor belts are very crucial tools for a lot of industries that works with heavy stuff everyday.

It's not easy moving a lot of heavy stones and rocks. Stone conveyor belts support not only by moving these materials quicker but one also ensures that there is added safety. Imagine trying to transport giant piles of rocks by hand or tiny machines at such a cumbersome rate and with that hazard potential. Stone conveyor belts, such as those sold by BEDROCK are built to handle heavy loads non-stop. Their surfaces are tough and robust enough not to tear easily, even if sharp rocks scratch them. The way in which the belt is designed also allows for stones not to fall off during movement, helping to keep any work site clean and safe. These will be found labor-saving in many mines and quarries in which such bands save the employment of heavy human labour, and increase the rate of work. For instance, in a rock quarry block stones are cut and then dumped on the belt. The belt moves these stones to crushers and trucks, which is faster. Without such belts, moving the materials would take many trucks or workers and slow the project down and cost more. In addition, stone conveyer belts are made to withstand wear-and-tear of various weathers. They resist rain, dust and heat well. This ensures work can proceed without breaks for belt replacement. BEDROCK’s belts are proven to perform well even in the harshest of conditions. So these belts are not only convenient — they’re a necessity.

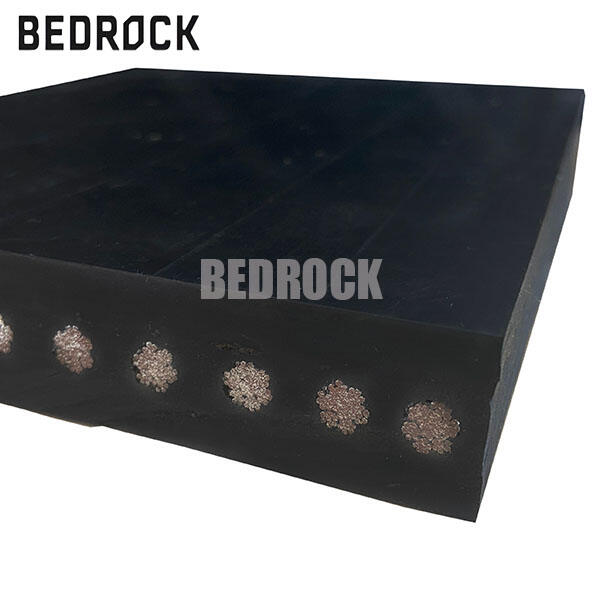

It is imperative to choose the correct AND suitable stone conveyor belt system as not all of them can transport heavy stones or work in demanding conditions. We know BEDROCK doesn’t stand for that, which is why we make belts that keep up with you. When selecting a belt, start by considering the weight and size of your stones. Larger stones require thicker, harder belts. Some belts have additional layers added inside to help reduce cuts and tears. It’s also wise to consider how quickly the belt has to travel. If the belt ran more quickly, stones could be lost. But if the pace is too slow, the work can remain stalled. Another thing to check is the surface of the belt. Rougher surfaces hold stones better but can wear out more quickly. Smooth surfaces are longer lasting but stones could potentially fall and require side guards. There are various types of belts to serve different purposes BEDROCK provide such kind of belts. The oil, chemical and heat resistance of the belt is one of the key factors. At times, stones may be wet or oily, and the belt should not disintegrate on contact with this. C) Our belts are built to withstand these issues. Also relevant is how easy a belt is to fix or replace. A belt that cannot be fixed can lead to hours of downtime. What’s more, the design of BEDROCK makes it easy to repair quickly, which is a smart way to save time and money. Lastly, and overall is the cost. It’s hard to resist going for a belt that costs very little, but these belts tend to wear out quickly and be more expensive in the long run. Patented Flip-Belt TensionerProven in tens of thousands of miles and passed all our tests for strength and durabilityPremium beltsIt just makes sense to put a strong belt on your BEDROCKREDUXYour old belt can be super long! That saves money and keeps business running smoothly. Selecting the correct belt is a carefully considered decision, but it can make all the difference when tackling heavy-duty work.

Stones and rocks in their natural form are a result of eruptions and deposits that have been under pressure for a long time in the Earth till they eventually hardened into making stones or rock shapes. Stone Conveyor Belts -: Stone conveyor belts are ideal for the transport of stone, used as an industrial construction material due to its extraordinary strength. But as with any machine, there can be troubles with these belts. Knowing how to troubleshoot common problems can keep the belt running well for a long time. One frequently encountered problem is belt mis-tracking. This occurs when the belt slides to one side instead of remaining in the center. This can, in turn, lead to belt edge and roller wear if allowed to continue. Workers must also adjust the rollers to keep the belt centered, and they should inspect the belt’s position on a regular basis to ensure it is where it needs to be. Another problem is that of belt abrasion. Conveyor belts may be subject to impacts from the carrying of heavy, sharp materials. In time this weakens the belt and makes it more likely to snap. Belts made with durable components such as those found in BEDROCK belts is one way to combat this issue. And routine inspection serves to find worn parts early so they can be replaced before they have a chance to cause more serious damage. Sometimes, stones will drop off the conveyor belt and wind up lodged in the machine, causing jams. Preventing these jams is as simple as keeping the belt clean and getting stuck stones off of it quickly. The belt’s motor and rollers may also encounter issues such as becoming stuck or loud noises. Popping the parts out and oiling the moving parts can keep them to running like new. And last of all, conveyor belts are susceptible to weather. Hot sun can dry and crack belts around the fan, while cold temperature can make them stiff and cause them to break. WEATHERPROOF Maybe--but using weather-resistant belts from BEDROCK and storing the belt correctly when not in use will address this issue. Understanding these common problems and easy fixes, employees can maintain stone conveyor belts and keep product moving without any unexpected downtime.

Choosing the right tools and equipment for large construction projects is very important. There are so many different tools to use when it comes to moving large stones with as much speed and safety as possible but stone conveyor belts is one of those indispensable tools. Purchasing conveyor belts wholesale means that you are going to be getting many belts at one time from a single manufacturer. Buying this way has many advantages, particularly for large projects. First, wholesale typically saves you money per belt. This is due to the fact that suppliers such as BEDROCK offer discounts on orders in bulk. If a project requires lots of belts, purchasing wholesale will save significant compared to buying one at a time. Second, wholesale purchasing insures that there are enough belts for the project. Construction work may shut down if a belt break goes unreplaced. Purchasing belts in bulk ensures workers always have one available. This helps the project to remain on schedule rather than get held up. Another reason is that wholesale sellers, like BEDROCK, sell good quality belts that have long service life. Trust the brand when buying a lot of belts, so you can have ones that work right and do not break. WORK SHARPINDEPENDENT OF BEDROCKBelts for any project, strong and built to haul the big rocks! And buying in bulk can save time, too. Instead of ordering belts several times the project manager can order once and have all the belts he need supply him. That means less waiting, and fewer problems with delivery. Wholesale purchasing also aids in planning. The team can better schedule maintenance and replacements, knowing exactly how many belts you have. For large construction companies, saving money, ensuring that there are enough belts on hand, and obtaining a quality product in a timely fashion are all high priorities. Which is why it pays to buy stone conveyor belts in bulk from BEDROCK for the best deal on all construction projects.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.