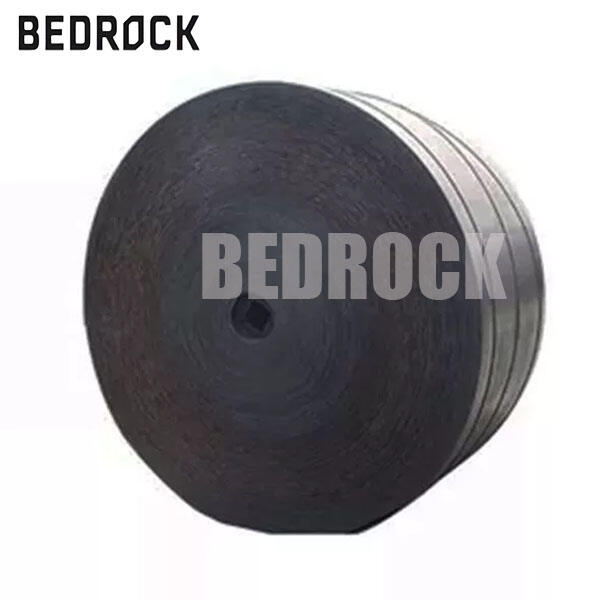

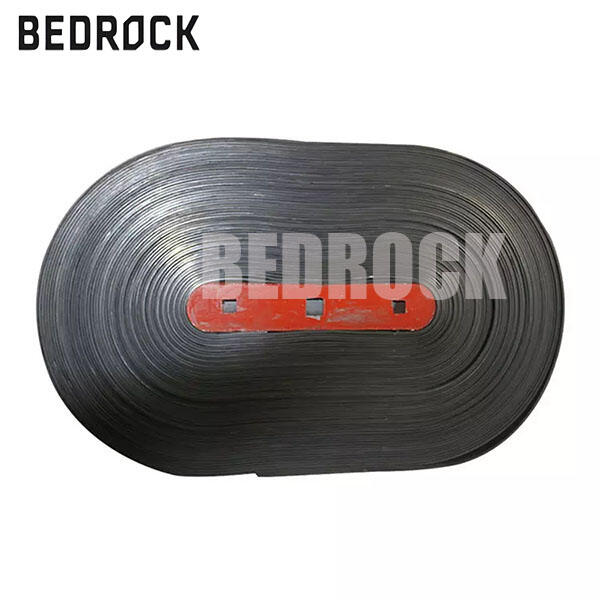

Fabric Rubber Conveyor Belts are a valuable item for lots of markets. These belts facilitate transport of material from one place to another and decrease help hoisting. Picture a manufacturing facility with hefty points that need to be moved speedily. Absolutely nothing could be packed and unloaded by hand as fast as with conveyor belts. BEDROCK is a business that creates high quality fabric rubber conveyor belts. They are made to perform well and hold for years. These belts are worn in a variety of work environments — from warehouses to building websites to also food manufacturing facilities. Knowing how to select the right one can change everything for how well a company runs.

For any business, choosing the correct fabric rubber conveyor belt is extremely crucial. First, consider the materials you will be bring. There are some fabrics that are heavy vs. light-weight. When you're bring something hefty, you need a strong belt. For circumstances, if considering hefty products, belts should be of thick rubber with fabric support. On the other hand, if you're communicating a lighter substance you might find the thinner conveyor belt is a better suit for your process. Then think of the conditions for which this belt will serve you. Is it hot or cold? Will it be wet or dry? For instance, if you work with a fertilizer conveyor belt in an area where water is present, you will want to select a water-resistant belt.

Size of the belt is also a key factor to consider. A bigger belt will have the ability to hold more products at the same time and might also cost more. A slim belt is less expensive, but holds less. Consider how a lot you will need to move, and select a dimension that is finest for you. You also should consider how quickly you would certainly prefer to move the products. It may run quickly, it may run gradually. Find a belt that can suit your functioning speed with no problems.

While the purchase of fabric rubber conveyor belts many buyers comes up with problems. A common issue is the belts might wear prematurely. This can occur if the belts are not of high quality. For instance, if a belt births hefty tons but has weak fabric, it will be broken or torn. The belts are often worn earlier than they should be, requiring buyers to purchase new ones very early and incurring more costs. Another problem is that it is not the right dimension. Many people may cannot measure their equipment accurately, and as a result receive an ill-fitting belt. Loose belts lead to bad belt efficiency or also complete breakdowns of the system.

Fabric reinforced conveyor belts are ideal for mining, mineral processing, quarrying, earth moving and agriculture. They can also be used on both sides and at the center. These conveyors make materials move efficiently and speedily from one spot to the other. When we discuss efficiency, we’re referring to getting faster and better at what you do. Fabric-rubber conveyor belts are easy to operate and they enable the transport of various kinds of metallic materials at all times. They convey such items as boxes, parts or food products from one area of a factory to another. Instead of workers lugging these items around by hand, that toil is done via the cement plant conveyor belts. This saves time and energy. Less labor is necessary to produce products, and companies have a new source of capital — the money earned from these automated processes.

It's a brand that creates fabric rubber conveyor belts. These belts are made to work very well and last a very long time. They're made of durable fabrics that will handle the toughest jobs. Rubber surface of the belt works in grasping most types of components production it favorable non slide belt. This is especially crucial in the situation of bulky or hefty fabrics. What is more, belts can be tailored to various devices and requirements too - production them very versatile. Not just do businesses conserve money with BEDROCK conveyor belts, but they also decrease expensive downtime - say goodbye to down time while waiting on devices to do their job. This outcomes in enhanced efficiency and more efficient source use, necessary in such a fast paced culture.

If you are in the market for fabric rubber conveyor belts and want to purchase them in bulk, or wholesale there are a few things you should be able to consider. First Look at the quality of belts. Good belts are going to last longer, run truer. Belts are made to keep your pants up, no matter how heavy they are. It's also important to be aware of the sizing requirements for your job and what kind of heavy duty conveyor belt will do the job you need. Various belts suit the needs of different industries, so knowing what you are using it for is essential. Another factor is the price. Sure, you want to get a great deal, but not at the expense of quality. Never mind that you'll save in the long run and probably wind up with one of those anyway. Additionally, consider the supplier’s reputation. Purchasing from a well-known company like BEDROCK, guarantee you with high quality customer support and service. And lastly, do the belts come with any warranties or guarantees? This can offer you a peace of mind and safeguard your investment.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.