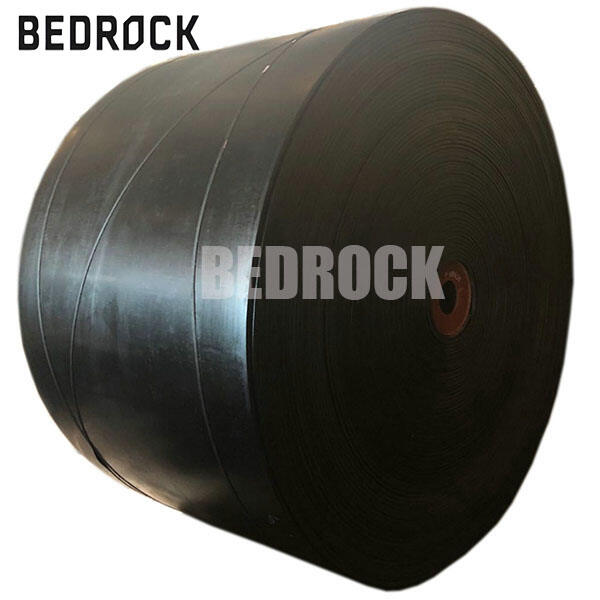

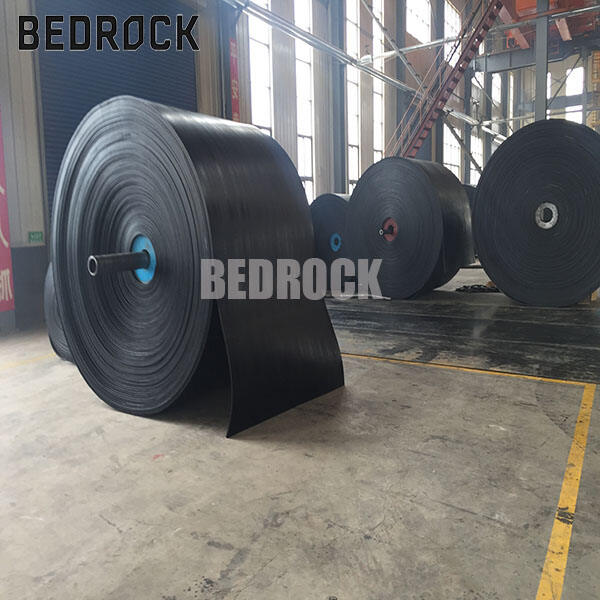

Coal conveyor belts are one of the most efficient ways in moving coal from one place to another for using it. They ease the transport of heavy loads over long distances without rest. Picture a long, strong belt — one that doesn’t stop moving for decades — that transports chunks of coal from where it is excavated to where it’s burned or stored. It’s this belt that has to be tough, because coal is heavy — and it can be hard on stuff. At BEDROCK, we design our coal conveyor belts to go beyond just the ordinary, with great care taken to ensure that all our belts are constructed to meet and exceed your specific systems needs. It doesn’t snap easily and your work goes quite smooth. The right conveyor belt saves time, money, and will outlast other belts – so make it a part of our workday. For instance, our EP Conveyor Belt is specifically designed for heavy-duty applications.

When it comes to purchasing a coal conveyor belt, there are concerns that new buyers may place at the top of their list. The first thing to consider is the belt’s strength. Coal is heavy and can be jagged, so the belt needs to be strong — high-quality rubber or a similar hardy fabric material that won’t tear under pressure. At BEDROCK, we stack our belts with 1000 lbs of tough and it proves itself so they last for years despite coal’s rough edges. And the width and length of the belt matter, too. If you have a big mine or factory, a narrow belt won’t carry enough coal and work will stop. You need a belt that is just right for you. Then there is the belts resistance to heat and fire. Coal can be a source of dust or sparks, and the fire-resistant belt helps make sure all is safe. Our BEDROCK belts have this feature built into them. Don’t overlook it’s speed either. It needs to move quickly enough that your production can keep up with it, but not so fast as to cause coal to slip off or for the belt itself to wear out at an unsustainable rate. Lastly, find belts that are easy to install and maintain. Some belts require special tools or a lot of time to repair. With BEDROCK belts, you are led to simple installation and trouble-shooting with no need to travel. When purchasing in bulk, it is wise to request samples or testing data. This goes to show just how strong and safe the belt truly is. Picking wisely at the beginning lowers headaches later. It seems like a good idea to buy a cheap belt, but if the thing snaps all the time, it costs money both in repair and in lost work. BEDROCK guides you to find the optimal equilibrium between price and quality, so that your investment is paid off.

It can seem like a few challenges when you want to find the best wholesale coal conveyor belt. You need someone who delivers great products and supports what they sell. At BEDROCK, we have learned that trust is something that accumulates with years of working shoulder to shoulder with customers and knowing their needs through and through. The name of the game in this business is trust; if a manufacturer isn’t asking questions or willing to provide some answers, something’s off. A quality supplier will gladly share specifics about their belts with you, like the types of materials they use and how each belt really holds up in actual mines or whatever your application may be. They answer questions clearly and they don’t hide problems. It is essential to ensure that your supplier has a solid support after the sale. Belts sometimes have problems or need to be replaced, and good vendors assist promptly. BEDROCK ensures that its customers have fast, knowledgable help at hand when they need it most. In addition, seek out vendors who adhere to rigorous quality standards and test each batch of belts. That means you can rely on products that performing very well, same as others. Some vendors only produce cheap belts that prove all too soon to be of poor quality but a dependable one takes great pride in long-lasting products. Price matters but don’t select only on the basis of low cost. Sometimes you pay a little bit more for less headache and added belt life. You also can find reputable vendors by asking other companies what they use or attending industry events where suppliers demonstrate their offerings. BEDROCK also hits the road to attend events, and there we have loved meeting customers and sharing how our belts are made and tested. Another thing to keep an eye out for are suppliers that have clear delivery plans. When you buy in bulk, you require belts timely so as not to let your work halt. BEDROCK will Get It Done as promised, because we get delays are a big deal. At the end of it all, selecting a trustworthy source is about following your business instinct and picking a partner that cares deeply about your success – not their product moving off the shelves. BEDROCK hopes to be that partner and assist your business in running efficiently on a daily basis.

Conveyor belts for coal are one of the most typical large use conveyor machines. They can carry coal from a mine to a power plant and over long distances. Since then, people have been working diligently to make these conveyor belts better and smarter. Today, the latest developments in belt conveyor technology begin to make some of the cleanest burning fuels even safer and more efficient to use than before. One major upgrade is the application of special materials that make the belts last longer and stand up to damage. These materials can also withstand the heat, sharp coal edges and extreme weather without breaking down quickly. A newer thought is to attach sensors to the conveyor belts. These sensors are monitoring this belt at all times and when there is something wrong like the belt’s slipping or too hot, they know. That way, workers can correct problems before they become large and bring the belt to a halt. And at least some conveyor belts are now equipped with smart systems that can adjust speed based on the amount of coal needed to move. It saves energy, and facilitates the process overall. We employ this new technology at BEDROCK to ensure our coal conveyor belts are resolute and intelligent. We want to help factories and mines transport coal more efficiently, while protecting workers. This new equipment and the material allow coal conveyor belts to work better and last longer, a saving of money and the environment through energy reduction. For example, our High Quality Cheap Price Rubber Conveyor Belt is designed to meet these demanding standards.

Coal conveyor belts should always be kept working efficiently because they are essential to moving coal around and need to withstand heavy loads and use every day. If the belts snap or fail, it can cause major issues — and be costly. Regular maintenance can help ensure that conveyor belts last a long time. This entails inspecting the belts for wear and tear, such as cracks, holes or loosened parts. It’s also important to clean the belts because coal dust and dirt can accumulate and damage them. Here at BEDROCK we recommend keeping the belts clean and free from sharp edges that could cut into the belt. Conveyor belts can also be kept healthy by ensuring the right tension. If the belt is too tight, it can stretch and snap. If it is too loose, it can come off the rollers. By being vigilant in ensuring the belt is tensioned you can avoid these problems. Also check the rollers and pulleys that hold up the belt. Those parts can harm the belt if they are either broken or dirty, and cause it to wear out quicker. By using the proper tools and following safety requirements during maintenance, workers are able to do a good job. BEDROCK offers clear paths to success while taking care of coal conveyor belts for companies. By taking these simple steps, those belts can last longer, perform better, and keep moving coal more safely day after day.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.