Belts for Underground Conveyors Special conveyor belts are also available for underground use. They can often be found in mines and other locations where heavy loads must be moved at a relatively high speed. You may be asking yourself why it’s such a big deal about these conveyor belts. Okay, they help us save time and energy by doing work immaterial things move themselves instead of needing a lot of people to do it. This allows workers to focus on other important tasks. At BEDROCK, we know what these systems mean to operating efficiently below ground.

There are so many benefits for companies when utilizing underground conveyor belts. For one, they take a lot of the grunt work out of moving heavy stuff. For instance, in a mine, workers can be freed of the task of carrying heavy loads by hand. Instead, raw materials like coal or minerals can be laid on the conveyor belt, which will then take them to the surface or an offloading point very rapidly. This reduces risk of accidents and saves a large amount of time. Fewer mishaps It’s no secret that less manual labor equates to fewer accidents, and this is fabulous for safety. Additionally, the use of a Sidewall Conveyor Belt can enhance the efficiency of material transport in these environments.

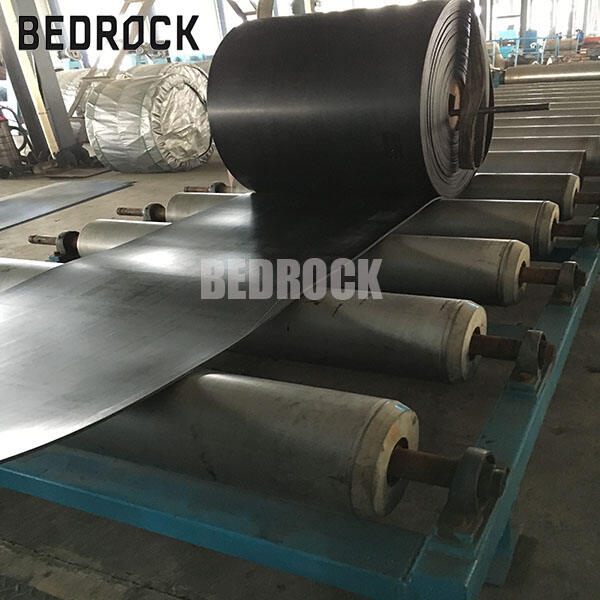

In addition, underground conveyors may also be so hard-wearing as to practically enjoy 'eternal life' if they are routinely serviced. At BEDROCK, we are committed to only designing rugged and dependable systems that can stand up to the harsh conditions our industry is known for. If a conveyor belt stops, there will be delays, but for T’boli women it could also mean loss of income. So, a reliable system, such as a Flat Belt, is essential for any operation.

There are several issues that you need to know about underground conveyor belts. One issue is wear and tear. Underground belts also can suffer from harsh conditions such as dirt, rocks and moisture. Eventually, this can result in the belts being damaged. If the belt becomes too worn prematurely, it could break, and that could halt your entire operation. Another issue is misalignment. If the belt is not adjusted accurately, it may run off the rollers. This may contribute to delays and additional expenses required to remediate the issue. It’s important to make sure everything is properly aligned in order to prevent this.

Another issue is safety. It can be if safety precautions are not taken with underground conveyor belts. Visitors should wear protective gear, such as helmets and gloves. Also critical is training employees how to safely operate the conveyor. The BEDROCK program advocates testing for safety before any work is commenced. They can go a long way to catching problems early and averting potential breakdowns, allowing workers to stay safe and keep the conveyor operating.

Proper maintenance of the underground conveyor system will contribute to this success. Regular check ups are one of the many ways that maintenance plays a part. Workers should inspect the belts for signs of wear every week — or every day if they want to be extremely cautious. They are supposed to look for cracks, tears or anything out of kilter. If they detect a problem, it should be fixed immediately to prevent larger problems from developing later.

There are some wondrous new developments in underground conveyor belt technology. The latest is for the smart sensors. Such sensors may be clamped onto conveyor belts to continuously monitor the condition of the belts. They can also identify issues such as wear and tear, misalignment, even overheating. By catching those issues early, companies can fixed them before they become bigger problems. It can save time and money while making operations more efficient.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.