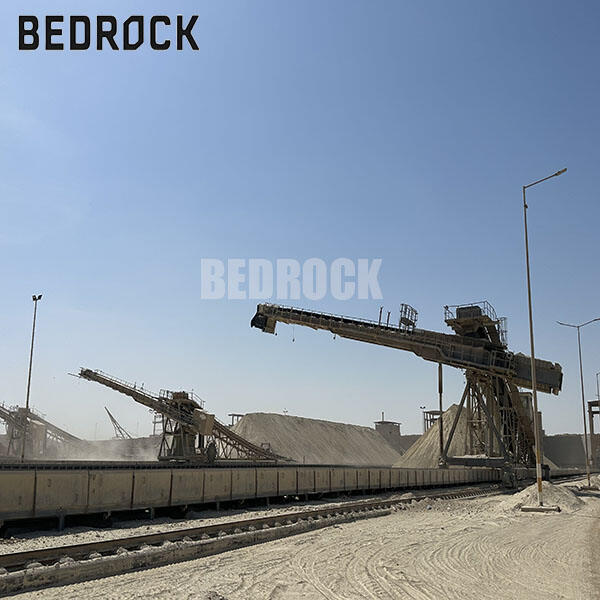

This is of particular importance on the stone crushing industry where you are dealing with big material. The EP200 belt has strength to last longer than the rest. Our mining conveyor belt for sale is also suitable to work on, due to the excessive generic raw materials in the production of other alternating products with stone crushers operation, making it convenient and way faster.

Also, the EP200belt is specially designed to hold the materials more efficiently. This means that it is less likely for stones and crushed materials to fall off as you transport them. This is a big help to the cleanliness and safety of work area. It also means less time spent retrieving fallen materials.

Selecting the correct chemical resistant conveyor belt will depend on your specific requirements. Size and weight of the items First of all, you should take into account the size and weight of the items that will packed in boxes. The EP200 table will support a lot of weight but it’s nice to know that it will work with your stone sizes. If you are dealing with really big rocks, you may require a belt that offers more support.

At BEDROCK, we can assist you with selecting the best fertilizer conveyor belt for your requirements. We know the difficulties that producers face behind every square foot, and we want to help you do what you do best: product quality material. The money you can save as a result of buying the appropriate conveyor belt for your enterprise is going to go a long way.

Issue with dust and dirt as well. In stone crushing applications, some other dust can build up on the high temperature resistant conveyor belt can cause the belt to slip, and when it does, the belt isn’t moving the stones as efficiently. Slipping belts can result in jams to the machine. Maintaining the belt is also critical. Keeping the belt dust free by scraping or brushing also helps maintain good operation.

If you are acquainted with other businesses in the stone crushing industry, they may have their heavy duty conveyor belt manufacturers have been long-time partners. Hearing from people who have been through it can be a time-saving, not to mention nerve calming, endeavor. You might also want to attend industry trade shows. You will also be able to meet with multiple suppliers face-to-face at these events.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.