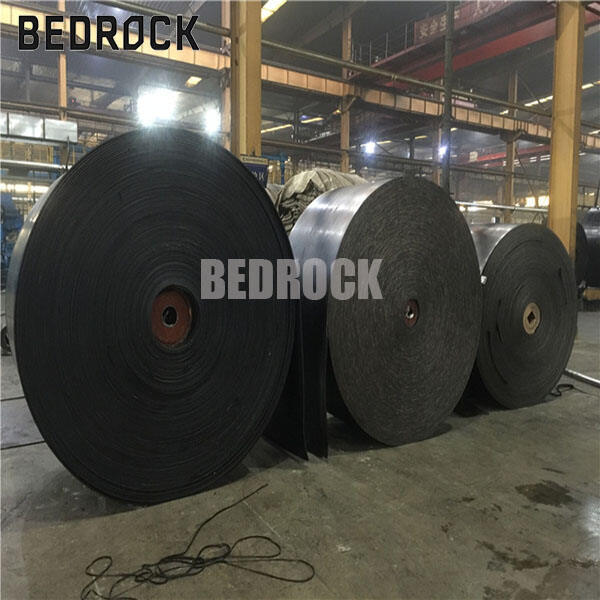

The machines that keep cement plants running need to be strong for moving heavy bags and powders from place to place. The conveyor belt is one such very important invention. It’s a bit like an endlessly moving road through which cement or raw materials travel inside the plant. The work gets slower and harder without a decent conveyor belt. SPRINGFIELD, ARKANSAS: BEDROCK has developed conveyor belts with the towing industry in mind that are specifically made to move heavy loads and remain durable. These belts are time saving and keep the cement flowing smoothly during production. If you are interested in heavy-duty options, check out our EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling.

Choosing the correct conveyor belt for a cement plant is extremely important. Cement is of course rough and heavy, so the belt needs to be tough and last for many years. There’s two major factors: the material of the belt. Some belts are composed of rubber and fabric that is both strong and flexible. The belt should not break or wear prematurely since replacing it often costs money and halts work. Additionally, the belt’s surface must have sufficient friction to prevent slipping of the cement. If the belt is too slippery, the cement can slide off and create a mess. At BEDROCK, we make sure the cement stays put regardless of how hurried the belt is moving by designing belts with unique surfaces.

The belt also has heat and chemical resistance. Cement plants are hot, and dust or chemicals can touch the belt. A belt broken by heat or chemicals will degrade in a short time. BEDROCK is made of materials that can withstand tough environments. The width of your belt also makes a difference. Thicker belts generally last longer but might be heavier and require more power to operate. The perfect thickness will depend on the size of a plant and how much cement the belt needs to carry each day. For high-performance belts, consider our Industrial Conveyor Belt Manufacturer Price, Heavy Duty Mining EP250 Chevron Rubber Conveyor Belt.

If you are seeking a supplier for your conveyor for cement, look to see if they have the belts “designed” specifically for conveying cement. A few belts may have been designed for food or light-duty processing applications and they will just not cut it amongst the rough conditions found in cement plants. BEDROCK’ s belts are constructed from hard-wearing material and have been tested dozens of times before they end up on a customer. Also, a reputable supplier will provide after sales services of the belt. From time to time belts require repairing or shifting, and BEDROCK offers service to make sure your belts are turning along!

Price is frequently top of mind for consumers, but the lower-priced belt might not be the cheapest in the end. If you buy cheap belts, they turn into broken belts and then there’s downtime and repair time. BELT King’s belts may be more expensive initially, but they save you money by lasting longer and requiring fewer replacements. If you prefer to compare the price of desirability with some form of measured performance, great! Another means to acquire trustworthy belts is by seeking the recommendations of other people in the cement company. Word-of-mouth is key to finding suppliers who live up to their promises.

Quick and safe transporting of heavy materials such as cement powder, sand and gravel in the cement industry is very important. This is where conveyor belts come into the picture: They are a type of continuous, moving band or belt that transports materials from one place to another within a factory or on construction sites! Conveyor belts are the ideal solution for the cement industry due to what is described above, tearing, breakage of edges and wear typically induced by impact or sliding on heavy and large lumps falling from a height. The BEDROCK conveyor belts are custom designed for a variety of applications and uses. They can function in challenging conditions, such as when there is dust, heat or sharp rock. These belts are made to be smooth and dependable so that the materials do not nest or jamb as they are moved along. That allows the work to proceed without interruptions, accelerating and possibly decelerating waves that might reduce its speed. For more robust options, consider our High Quality Cheap Price Rubber Conveyor Belt 4 Ply 800mm Belt Flame Resistant EP Conveyor Belt. Another reason why conveyor belts are perfect for this is that they can be made in different sizes and lengths. This allows the machines to land in small or large factories and get into places where trucks or workers have a hard time getting heavy loads. BEDROCK conveyor belts also incorporate special rubber and metallic layer designs to protect against premature wear. This can save time and money since the factory doesn’t have to continuously make repairs or replace belts. In summary, when it comes to the cement industry, conveyor belts are essential not only because they’re convenient, but also because they’re strong and safe, and move materials along without a problem so that plants function better each day.

Quality Matters When Purchasing Conveyor Belts For The Cement Industry Quality matters greatly when you are buying conveyor belts for the cement industry, particularly if you are going to be buying a lot of conveyor belts at one time. Buying in quantity is many conveyor belts for a factory or construction site. If you do not have quality belts, they may fail or wear out prematurely. This leads to major issues such as halted work, loss of materials and even accidents. That's why it's important to invest in strong, dependable brand like BEDROCK. BEDROCK conveyor belts are built to last with high-quality materials. They're also tough; they don't rip (we haul heavy, sharp cement products and materials every day). When a factory purchases its various conveyor belts, putting in place good quality belts will mean far less on repairs or replacements down the line. Less down time, when the factory must temporarily stop working to repair broken belts, too. Downtime is hugely costly — the factory cannot create cement when it’s not running. It’s conveyor belts with a nod to quality from BEDROCK that keep the work flowing smoothly and safely. It’s also crucial to make sure that belts are all the same size and strength if buying in bulk. This means belts can be quickly replaced or repaired if something goes wrong. In such markets, buyers will need for belts and excellent customer support to make the choice of belts bingo! BEDROCK supplies these demand with best belts available and great customer support. it's really quality that counts as buyers purchase several conveyor belts for the cement industry so it saves them money and time, keeps them safe and steady.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.