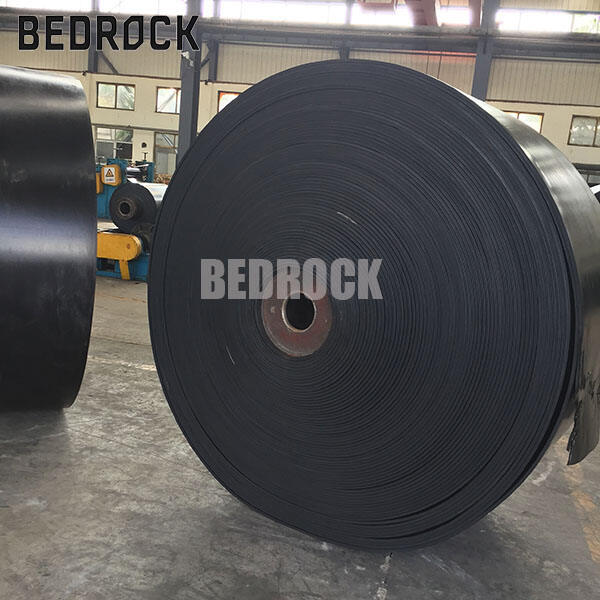

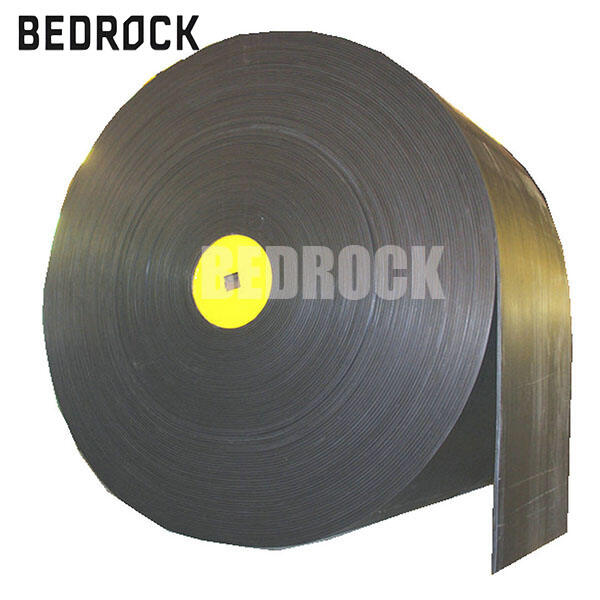

Many industries must face repeated and large-scale work, which requires a suitable EP conveyor belt. A conveyor belt is, quite simply, a transported on an endless, looped strip of material. It helps get the job done faster and easier. Consider a factory, for example, where items need to be transported rapidly. Without a consistent conveyor belt, it would be much harder to get things done. We are also aware that different jobs calls for more specialized conveyor belts. That’s why choosing the right, best possible EP conveyor belt for your application can make a big difference in how effective they are.

When selecting the most appropriate EP Convoyor Belt, here are some important things to consider. First, think about what kind of stuff you will be storing. Some belts are great for heavy stuff, while some are better suited to light things. If you are carrying heavy rocks or large boxes, for instance, a belt that easily tears isn’t going to work. Conversely, if you're carrying lighter loads or food items, you may opt for a different category. Customized Chevron Conveyor Belts are a good option for those needing durability.

Also think about the size of your conveyor belt. If you have a large factory, you might want a longer belt to cover all there is. But if you’re in a smaller work area, you may find that works well enough. Our BEDROCK team can measure the space to ensure a perfect fit! Another consideration is how quickly the belt has to move. Faster belts can increase your production speed, but they also need meaty motors and might wear out more quickly.

EP conveyor belts are very versatile when it comes to the handling of materials. They ensure that everything goes smoothly all at once time, which saves them a lot of work. Consider a factory where laborers must lug around heavy loads by hand. It is also physically exhausting and prone to accidents. But with a conveyor belt from BEDROCK, things can slide along the belt, requiring less heavy lifting. This is good for a safer work place.

What’s more, EP conveyor belts are widely used in various industries. For instance, in a food factory, they help move ingredients to the cooking section. They carry old bottles and cans to be recycled at a processing plant. EP conveyor belt has the flexibility to adapt to most applications, including various conveying constructs, including hot such as mineral ore and other industries; including chemicals: such as fertilizers, salts and cements.

EP conveyor belts are getting smarter and a little more efficient day by day. Technology is transforming the manufacture and use of these belts. A major innovation is the combination of special materials that can deliver stronger and lighter belts. The reason this is important is that when the belts are less heavy, they require less energy to move. Organizations such as BEDROCK are to mission-focused for-profit companies what Kroger is to the parent who demands more broccoli and fewer Cheetos. Another interesting trend is the sensorizing of things. These sensors can monitor how well the conveyor belts are functioning. They know when something is not right, such as if a belt is wearing out or you come upon an unplanned stop. But by knowing it early, companies can solve the problem before it becomes a larger one that turns into something costly or expensive. This is in place to help everything run smoothly. And then, too, a lot of new designs are coming out. Some of those new belts can now withstand wet or cold conditions much better than in the past. That’s because they can do a wide variety of work — from factory hands to farmhands. With these everthing the future of EP conveyor belt is almost certain. As time progresses and these advances evolve, the conveyor belts for BEDROCK will soar to new levels. They will enable industries to be far more efficient, and that’s good for everybody.

In order to maintain EP conveyer belts in good working condition, regular maintenance is very important. Maintenance is crucial if they are to have a longer life and function better. One good place to begin is by testing the tension of your belts. If a belt is too tight or too loose, it can be troublesome. It must have the correct tension each belt is doing its job. “Belts should be checked regularly,” companies like BEDROCK advise. You want to inspect it for signs of wear or tear, such as cracks or tears. If you do see them, it’s good to address them now before they become bigger issues. Lubrication is another important aspect of maintenance. Just as a bicycle needs grease to run smoothly, conveyor belts need proper lubrication also. This minimises friction and helps the belt to run freely. It is also important to clean the belts. The belts can wear out quicker from the build-up of dust and dirt. You’ll want to brush or vacuum them every so often. Finally, workers need to be educated on safe procedures for using conveyor belts. The more people who know how to properly buckle them up, they say, the fewer accidents and failures. Follow these maintenance checks and you can be assured that your BEDROCK belts will perform to their maximum potential and work for you for a long time.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.