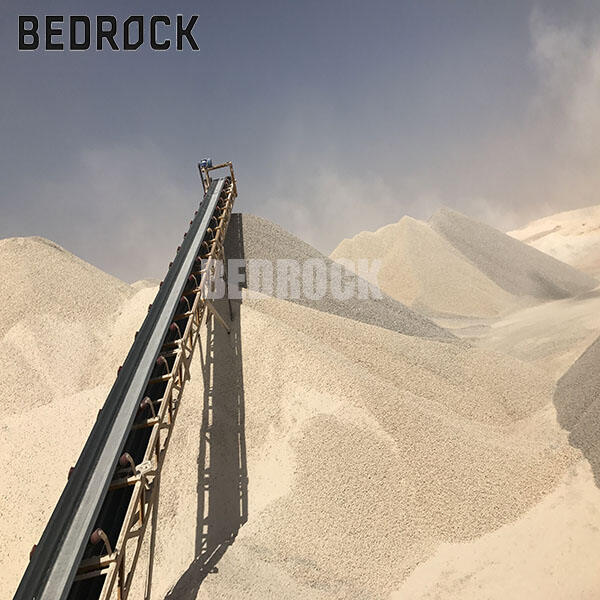

Mining conveyor systems are really important machines in mining, they help moving materials like rocks, ores and stuff from one spot to another. This make mining way more efficient and workers save lots of time plus energy. At BEDROCK, we know how much these conveyors matter so we try provide good quality solutions for different mining needs. You can find conveyor systems in big mines and also smaller ones, they keep everything running smooth and move materials safe and fast.

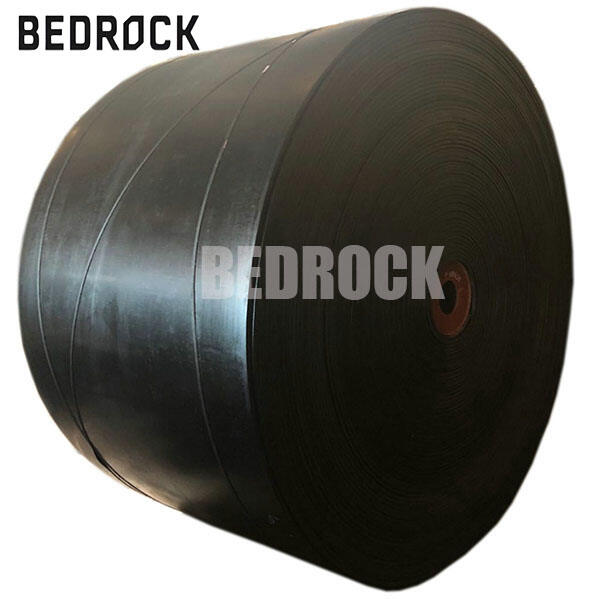

Finding a decent supplier for mining conveyor systems isnt always simple but its super important. Good suppliers can change a lot about the equipment quality and the service you receive. One way to begin is search online, lots of companies got websites where you see their products. Look for those with nice reviews and strong reputation. Also you can ask other mining peoples for suggestions, they maybe know trustable suppliers they used before. For instance, suppliers offering various types of Conveyor Belt solutions can be beneficial.

Another idea is go to mining trade shows or exhibitions. These places are great to meet suppliers in person, you ask questions and learn about their stuff. When you talk to them, better ask about their experience and how good their conveyor systems are. Its smart also check for warranties and support after sale. A reliable supplier will gladly give info and help pick right system for you. BEDROCK is knowed for reliable conveyors like the Flat Belt and very good customer service, we make sure clients get best products out there.

Mining conveyors sometimes have usual issues that people need watch out. One big problem is belt misalignment, if belt not straight it wears faster or can even break. To solve, regular maintenance is must, check alignment and adjust when needed so system runs good.

Also mechanical fails happen from wear and tear. To lower this risk, do routine inspections, look for wear on pulleys, rollers and other parts to catch early. At BEDROCK we suggest make a maintenance schedule to keep your systems in best shape. Being proactive help avoid big troubles and mining work goes smooth.

Mining conveyor systems are key machines that transport materials like rocks and minerals in mine from place to place. They are long belt structures carrying heavy loads over far distances. Biggest advantage is save time and labor, imagine carry heavy rocks by hand - it take forever and very tiring. But with conveyor, workers just load material on belt and machine move it where needed. So miners focus on other tasks like extract more valuable stuff. Also these systems work non-stop, no breaks needed like humans, so mining companies finish jobs quicker and better. Faster transport mean higher production, good for business. And using conveyors lower accident risks cuz workers stay away from danger zones more, they control from safe spot. Overall conveyors make material moving efficient, very vital for mining success.

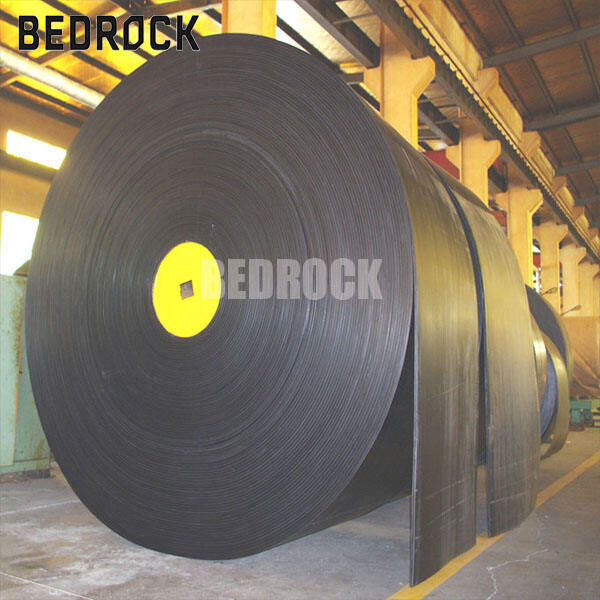

When searching for high-quality mining conveyor systems, some features are important to think. First durability is main thing, good system must last long in tough places with heavy loads. For example BEDROCK systems built to handle harsh conditions, so they dont break easy and save money later. Also size and capacity matter, pick one that handle your material amount, too small will slow work. Speed of conveyor important too, faster one move stuff quick which needed in mining. Flexibility also good - some systems can adjust or expand for different sites, no need buy new every time. And ease of maintenance, high quality ones easy clean and fix, less downtime. By look at these, companies like BEDROCK can get conveyor that work well and efficient for their needs.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.