Conveyor belts are particularly common in many factories and warehouses, it helps to move things from one place to another. But sometimes, items on the belt can slip or fly off, causing trouble or even accidents. That is why BEDROCK has made special anti slip conveyor belts. These belts are meant to hold items securely and safely in place as they travel. Not only do they assist workers in doing their jobs more effectively, they also safeguard products and machines. Without good belts, work can be slow and people can get hurt. BEDROCK’s belts have a long-term service life under various working conditions. They do make sure that everything stays where it should be, regardless of what kind of stuff is on the belt.

You think safety, when you’re thinking of factories or the big warehouse spaces. Workers need to work quickly yet safety is also a concern. A less visible hazard is objects that slide or fall on conveyor belts. When a box slides off, it can hit someone, or cause a chain reaction that jams up the whole line. This is why anti slip conveyor belts are essential. BEDROCK’s belts prevent this from occurring by holding items securely in place. Consider a wet or oily solid — normal belts could allow it to slide, but an anti slip belt has a surface which clings much more tightly. This also means workers don’t have to be as concerned with things falling or slipping. It reduces the risk of injury, which means fewer sick days and a healthier workplace. Safety rules in places even claim you need these belts to keep workers or products safe. We know this best because we have witnessed first hand how a great belt changes the flow of a factory. Not only do they help prevent bad things from happening, but they also allow the machines to run without ceasing. When a belt slips, machines must frequently stop so workers can adjust them. But with our anti slip belts, business remains smooth and efficient. It’s as if you’ve got a silent helper that is always on hand to keep everything standardized. The belt is trustworthy, workers can rely upon it and managers can trust that their team are safe. Accidents are prone to happen in the blink of an eye without that perfect belt, and rectifying them costs you both time and money. To overcome these difficulties BEDROCK manufacture non slip conveyor belts which provide the required friction to facilitate drive and prevent product slip. So safety means more than rules — it’s about making sure the work goes well every day.

All conveyor belts are not created equal. Some don’t last long or do not grip things properly. BEDROCK anti series conveyor belts are made for durability and strength, varying with your needs. For one, the belt surface is made up of materials that hold on just enough to keep things at a standstill and not so much as to trap items. It’s not easy to strike the right balance here, but we’ve put in a lot of work. Then, the belts are constructed with durable rubber or synthetic materials that can withstand heavy loads and tough conditions. They’ll never rip or wear down after endless use, day in and day out, for years. Just think of lifting a bunch of heavy boxes or sharp parts — a weak belt can get gnashed up in no time. Our belts don’t. Plus, the belts are resistant to heat, water and chemicals. Some of the factories are ones where liquids are handled or hot and the belt must not splatter it or slip. BEDROCK’s belts retain their grip and strength no matte what happens. Another important feature is flexibility. The belt must be able to flex around wheels and pulleys without cracking or deforming. If a belt freezes up or pops, the whole setup goes down. Our belts are flexible, wear-resistant and stay tight over the long haul. And the edges of the belts are well-sealed to prevent dirt and liquids from seeping into the machine and harming it. This attention to detail adds life to the belt and saves money on repairs. Lastly, the belts also come in varying sizes and thicknesses to suit a variety of jobs. No matter whether it’s the tiniest parts or the toughest heavy boxes, BEDROCK has a conveyor system built to perform and designed to last. All of these elements combine to make a belt that's tough, secure and durable. In my experience, the right belt can make or break how well a factory operates every day. And this is about more than just moving things; it’s also about doing it right and safely. For example, our Flat Belt options showcase our commitment to both safety and efficiency.

In factories and warehouses around the world, materials need to be able to move quickly and safely from place to place. That’s where conveyor belts come in. Conveyor belts are neat, moving walkways that help things move from one place to another — like boxes or food or parts! But then, the items on the belt can become slippery or slide off and slow things down, or worse yet lead to accidents. This is the reason why anti slip conveyor belts are extremely necessary. These belts have special textures or patterns that prevent things from sliding. When a conveyor belt refuses to allow items to slide, workers are forced to do more work in lifting the additional weight and flex out of the way, actually slow down the line as they work, move less product per hour on the line — all while curving their body low with each load. The belt anchors everything in place so less stuff tumbles around and gets damaged. That’s less waste, and fewer delays. For this reason, the entire business of transporting goods improves greatly. BEDROCK’s anti slip conveyor belts use strong, durable surfaces in addition to smart materials that help them hold on to whatever is put on the belt. This makes the belt less of a safety hazard to use, and helps workers complete their jobs at them satisfactory time. When materials don’t slip, machines do not need to stop frequently for troubleshooting. This is a time and dollar saver for your business. As the name suggests, anti slip conveyor belts from BEDROCK reduces( or does not allow at all) things to slip on the conveyor line.Be it boxes, cartons, cardboard products anything and everything will move safely and quickly without any spillage with good design of belt.

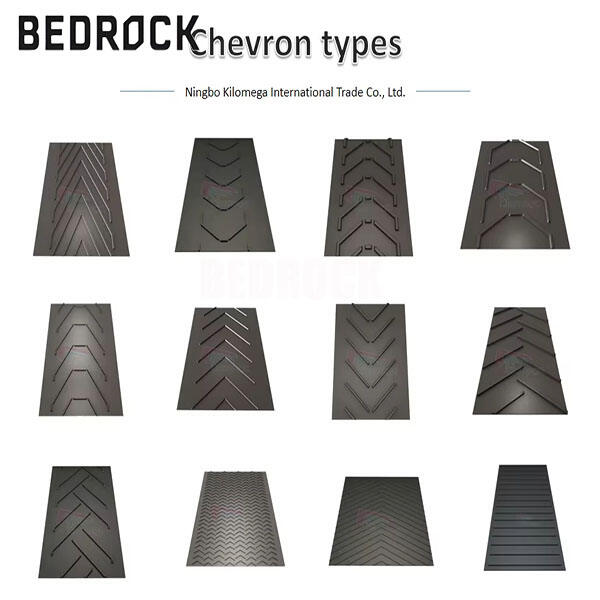

Various kinds of anti slip conveyor belts are required by different jobs. That’s because each sector is transporting different materials, and working in different ways. Food factories, for instance, require conveyor belts that are sanitary and safe for food. The company also produces special anti slip belts, that have smooth, but grippy surfaces so that are dirt and germs do not adhere to them. This prevents your food from falling out in the process of packing and is also secure. Elsewhere, in mining or construction, conveyor belts make heavy rocks or dirt easy to manage. These belts have to be tough and rough to keep the heavy loads from breaking or slipping them. BEDROCK provides durable anti slip belts through thick rubber or with special patterns that save heavy big things from slipping. At electronics or small-parts factories the material is light, but must be handled carefully. Here, BEDROCK’s anti slip belts have smooth surfaces that prevent tiny parts from slipping or falling. This is to ensure that the parts are secure and the work stable. Plus, some industries operate in wet or greasy environments that facilitate things slipping. BEDROCK supplies anti slip conveyor belts that not only resist water and oil, they keep materials from flinging off no matter what the weather or work environment. Companies can help ensure their products get from one place to another without slipping and sliding with the right kind of anti slip conveyor belt. BEDROCK has a wide variety of belts for many industries and those who wear them on the job will be able to do so more effectively. For example, our Rough Top Conveyor Belt is specifically designed for such tough environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.