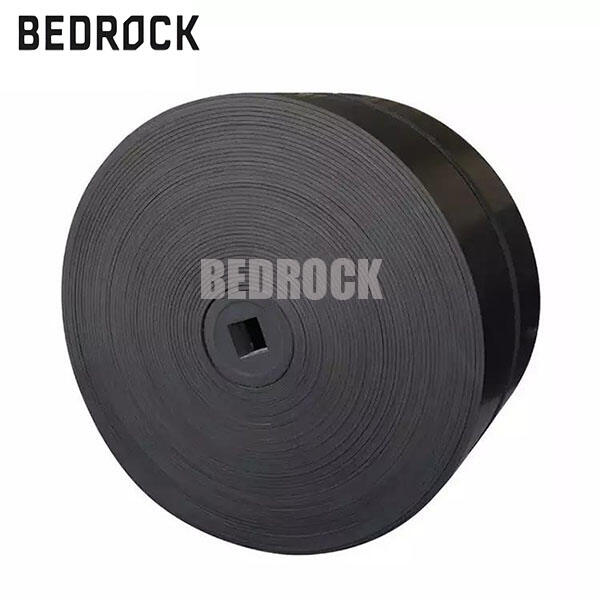

Many machines work to turn raw material, such as limestone and clay, into cement at a cement plant. A very important machinery is the Conveyor Belt. It transports heavy loads of materials from one place to another within the factory. Without a robust and dependable conveyor belt, the entire operation slows down or even comes to a complete standstill. Conveyor belts need to be rugged in a cement plant because they move rough, heavy materials like rocks and powder all day long. Bedrock is a maker of conveyor belts strong enough for this hard work. They keep workers safe and help enable plants to run smoothly. When you stop and think about just how much material is moving around via conveyor every single day, you begin to realize why it’s important to find the right conveyor belt.

Selecting The Best Conveyor Belt For Cement Plant Posted on June 25, 2018 by leizhanpaperpulper Whenever you are thinking of taking the production process to another high level, it is very important that you consider proper conveyor belts.

Choosing the right conveyor belt for your cement plant is no easy task. You need a belt that can hold up under the wear and tear of heavy materials like crushed stones or cement powder. First, there are definitely good and bad materials for belts. Rubber, fabric-layered and steel cord reinforced belt Some belts are rubber, others have fabric layers. For cement plants, sometimes a belt with steel cords inside is good because it won’t easily tear. The thickness of the belt matters, too. Thicker belts are more durable, but they may be heavier and less easy to maneuver. So, it’s a balancing act between your plant’s machines and how much material you move every day. Another consideration is the surface of the belt. A rough surface can catch hold of materials, preventing them from slipping as you move around. But a belt that’s too rough can wear out faster and become caked with dust, making it more difficult to clean. BEDROCK makes belts that keep this balance right, perfectly giving you a strong grip and good longevity. And consider the atmosphere inside your plant. If it’s very hot or dusty, the belt should absorb heat and not be degraded by dust. Some belts feature special layers to fend off these issues. Speed is another part. If your plant is moving product at max speed, the belt will need to handle that speed without stretching or snapping. BEDROCK conveyor belts are available to be test run at a variety of speeds so that you can choose the perfect speed for your plant. Maintenance matters too. A belt that is readily cleanable and repairable saves time and money. Seek out belts that have simple components and arrive with easy-to-follow directions. BEDROCK comes with plenty of assistance and advice to enable you to continue using belts for a long time. Selecting the best belt, then, is about a number of things at once: strength and thickness, surface and environment, speed and even maintenance. If you get all these things right, your cement plant will run better and work more consistently — and you will avoid many headaches.

Wholesale Buyers and the Perks of Buying in Bulk When purchasing plant conveyor belts for a cement plant, there are many reasons why wholesale is your best option according to company All-State Belting.

Purchasing conveyor belts in bulk can save you some money especially when you are working for larger cement plants, or companies with few plants to maintain. Wholesale buyers tend to get better prices when purchasing in volume, as manufacturers like BEDROCK can plan production more easily and cut costs on materials. That’s in part because buyers pay less per belt than they do when buying just a few at a time. But it’s about more than just price. By purchasing multiple belts at once, you have replacements in reserve when a belt becomes worn down. For a livening cement plant, production is lost waiting for that new belt, money and time. Spare belts on hand also means less downtime and quick changes. Plus, customers can request custom designs when they buy in bulk. BEDROCK is capable of making belts with unusual features, for example extra heat resistance or with custom sizes that fit special machines. Custom orders are more effective when they come in bulk, rather than a piece or two. Another point is delivery. And with each purchase of multiple belts, BEDROCK schedules the shipping to suit your needs so you’re not left holding on to belts or waiting for them. Also, wholesale buyers develop a strong relationship with intelligent manufacturers. That translates to quicker service and priority support, as well as sometimes extra training for your workers on how best to use and maintain the belts. Training is beneficial and helps prevent belt damage or safety issues from mistakes. And it can even help buyers better plan for the future, occasionally. Then the system can predict how many belts it will need, and not order them at the last minute, giving workers what they need to keep the plant running. BEDROCK understands the struggles that come with running cement plants and collaborates with wholesale consumers to offer options that are suited to their needs. Buying conveyor belts in bulk is wise because it will result in savings, reduced risks, and keep the floors running smoothly every day.

Conveyor belts are particularly useful in the cement industry because they can quickly move heavy materials (like cement, sand, and gravel) from one place to another. The right conveyor belt can save money and be a positive investment in both the short and long term. Its Quality That Counts Serving the cement industry we work on the principle of using best quality materials that together with unique innovative design guarantee products from last many years. Conveyor Belting CoastLine BEDROCK supplies conveyor belt for the most brutal crushing applications throughout N.C., S.C., and Va. All belts are engineered to meet all requirements of your application, including: resistance to ripping tearing impact shredding cover wear life and more. That means spending less on repairs and replacements. Purchasing from a company like BEDROCK makes sense because they know what cement plants require and are able to supply belts that specifically suit those requirements. Plus, BEDROCK’s belts are made to withstand tough loads and tough conditions from the cement that is hard on them as it is transferred. When purchasing your conveyor belts, check if the seller has excellent customer service so that they can help you with any of the issues. BEDROCK also offers nice words and technical assistance to ensure the belt is being installed and used properly. What’s more, they can play a role in selecting the appropriate belt for ascertaining conveyor size and speed. Another reason is that BEDROCK can deliver in short time, preventing any delay on production. Sourcing low cost conveyor belts – you‘d better get a quote from BEDROCK and compare with others. The lesson: Don’t go for the cheapest belt Since the least expensive belts are not necessarily going long term, you should invest in belts that save money over time by not breaking all of them way too often! In conclusion, BEDROCK is a reliable source of conveyor belts for the cement industry as their products are strong, reasonably priced and well-supported by the company’s service.

There are a number of reasons why the belts in cement plants can fail. Identifying these causes helps avoid problems and keeps the plant running smoothly. They’re often worn out due to the wear and tear on the belt. Cement products are gritty and large, which will wear on the surface of he belt, eventually. The belt itself may wear out quicker if it’s not made from durable material such as the one used by BEDROCK. Another cause is misalignment. When a belt isn't running straight on the rollers, it may slip off or wear out quickly. This is due to your conveyor system not being configured correctly or parts are loose. Similarly, objects with sharp edges or stones and other debris combined with cement can cause the belt to be torn, cut. Belt failure is the result of poor maintenance and sometimes, driving on an oil-soaked belt. Without regular cleanup or inspection, small problems become big ones. For instance accumulated dirt may make the belt slip and failure to notice damages on time will ultimately result in breaks. The heat as well as humidity in the cement plants can also deteriorate the durability of the belt over time, more so when it is not specifically designed to tolerate such extremities. In order to avoid belt failures, one must not risk using low quality belts, including imitation products promoted by BEDROCK BELT ASIA Pac the use of which might trigger belts failure and endanger production. W-9 Inspections shall be conducted on a regular basis to assess the condition, alignment and tightness of components. Wipe down the belt and rollers so that your system runs well and doesn't slip. Training workers to spot the early signs of belt problems helps fix issues before they lead to a breakdown. Suggest a guard covers and removing objects that might hit the conveyor are easy solutions. Doing so will help to prevent extreme losses and high costs of repairs by implementing these preventative measures, including choosing the most durable BEDROCK belts.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.